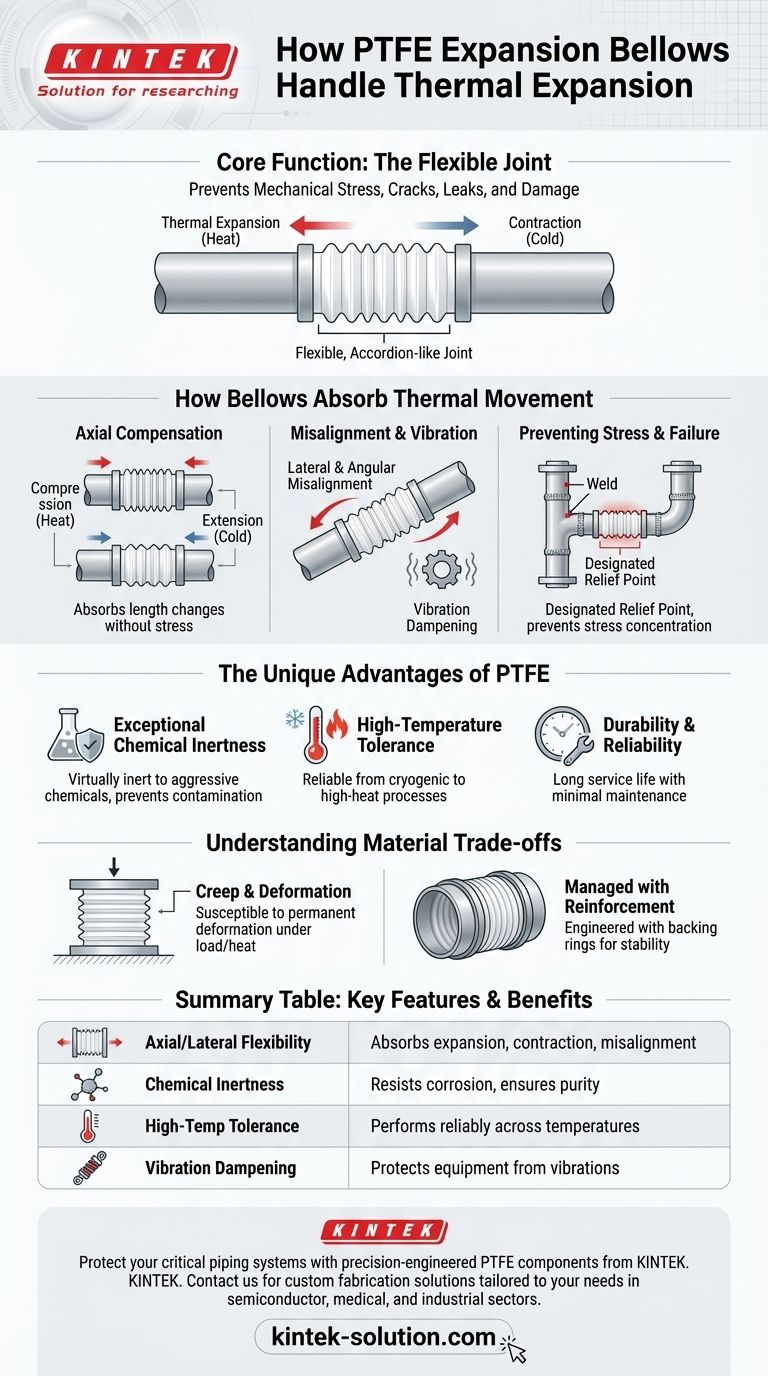

At their core, PTFE expansion bellows serve as flexible, accordion-like joints within a piping system. They are designed to compress and extend, absorbing the dimensional changes that occur when pipes expand with heat or contract in the cold. This controlled flexibility prevents the buildup of mechanical stress, which would otherwise cause cracks, leaks, and damage to the rigid pipe sections and connected equipment.

The essential function of a PTFE expansion bellow is to isolate rigid piping from the powerful forces of thermal expansion. It accomplishes this by leveraging PTFE's unique combination of flexibility, chemical inertness, and thermal resistance, but requires careful design to manage the material's inherent softness.

How Bellows Absorb Thermal Movement

A piping system without a point of flexibility is vulnerable to self-destruction from temperature changes. Expansion bellows introduce a controlled point of movement to safely dissipate this stress.

The Principle of Axial Compensation

The primary function of an expansion bellow is to compensate for changes in the pipe's length, known as axial movement.

As the pipe heats up and expands, the bellow compresses. As the system cools and the pipe contracts, the bellow extends. This accordion-like action absorbs the change in length without transferring stress to the pipe anchors or equipment nozzles.

Handling Misalignment and Vibration

The same flexibility that absorbs thermal expansion also allows the bellow to compensate for other types of movement.

This includes lateral misalignment (pipes that are slightly offset) and angular deflection (pipes meeting at a slight angle). It also helps dampen system vibrations from pumps or seismic events, further protecting the entire structure.

Preventing Stress and System Failure

By absorbing these multi-directional movements, the bellow acts as the designated point of relief in the system.

This ensures that stress from thermal cycles does not concentrate at weak points like welds, flanges, or valve connections. The result is a dramatic increase in system integrity, reliability, and safety.

The Unique Advantages of PTFE

While expansion joints can be made from metal or rubber, PTFE (Polytetrafluoroethylene) is chosen for its distinct combination of properties, making it indispensable in demanding environments.

Exceptional Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This makes it the ideal choice for pipes carrying corrosive fluids in chemical processing, pharmaceutical, or food and beverage industries, preventing both leaks and product contamination.

High-Temperature Tolerance

PTFE maintains its properties across a wide range of operating temperatures. This stability allows it to perform reliably in systems that experience significant temperature fluctuations, from cryogenic applications to high-heat processes.

Durability and Reliability

The combination of chemical and thermal resistance results in a long service life with minimal maintenance. This reduces costly downtime and enhances overall system reliability.

Understanding the Material Trade-offs

As a technical advisor, I must emphasize that no material is without its limitations. Understanding PTFE's inherent characteristics is crucial for proper application.

The Challenge of Creep

PTFE has relatively low stiffness, which means it can be susceptible to creep—a slow, permanent deformation when subjected to a constant load, especially at elevated temperatures.

Managing Deformation

To counteract creep and provide stability under pressure, PTFE bellows are often engineered with reinforcement. This can include metal backing rings or full encapsulation to prevent over-extension and ensure the bellow maintains its shape and function.

Dimensional Instability

The same high coefficient of thermal expansion that allows PTFE to be flexible also makes it sensitive to heat during manufacturing. This must be carefully managed with controlled machining parameters and the use of coolants to ensure the final product meets precise dimensional specifications.

Making the Right Choice for Your System

Selecting the correct expansion joint requires a clear understanding of your system's specific demands.

- If your primary focus is handling highly corrosive chemicals or meeting sanitary standards: PTFE is an unparalleled choice due to its chemical inertness and non-stick properties.

- If your system involves high pressures or significant temperature fluctuations: Ensure the specified PTFE bellow includes reinforcement, such as backing rings, to prevent creep and ensure long-term dimensional stability.

- If your main concern is absorbing vibration and minor misalignment: The inherent flexibility of a PTFE bellow makes it a highly effective solution for improving system stability and reducing mechanical noise.

Ultimately, a properly specified PTFE expansion bellow is a critical engineering control that protects your entire piping system by safely managing its response to thermal energy.

Summary Table:

| Key Feature | Benefit for Piping Systems |

|---|---|

| Axial/Lateral Flexibility | Absorbs thermal expansion, contraction, and misalignment. |

| Chemical Inertness | Resists corrosion from aggressive fluids, ensuring purity. |

| High-Temperature Tolerance | Performs reliably from cryogenic to high-heat processes. |

| Vibration Dampening | Protects equipment from pump or seismic vibrations. |

Protect your critical piping systems with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our PTFE expansion bellows are designed to handle thermal expansion, chemical corrosion, and vibration, ensuring system integrity and preventing costly downtime.

We specialize in custom fabrication, from initial prototypes to high-volume production, to meet your exact specifications.

Contact KINTEK today to discuss your application and receive a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications