Yes, PTFE expansion bellows are designed to meet a wide range of stringent industry standards. This compliance is fundamental to their use in highly regulated sectors, ensuring they meet critical requirements for material safety, purity, and environmental regulation, including key standards like FDA, ASTM, USP, RoHS, and REACH.

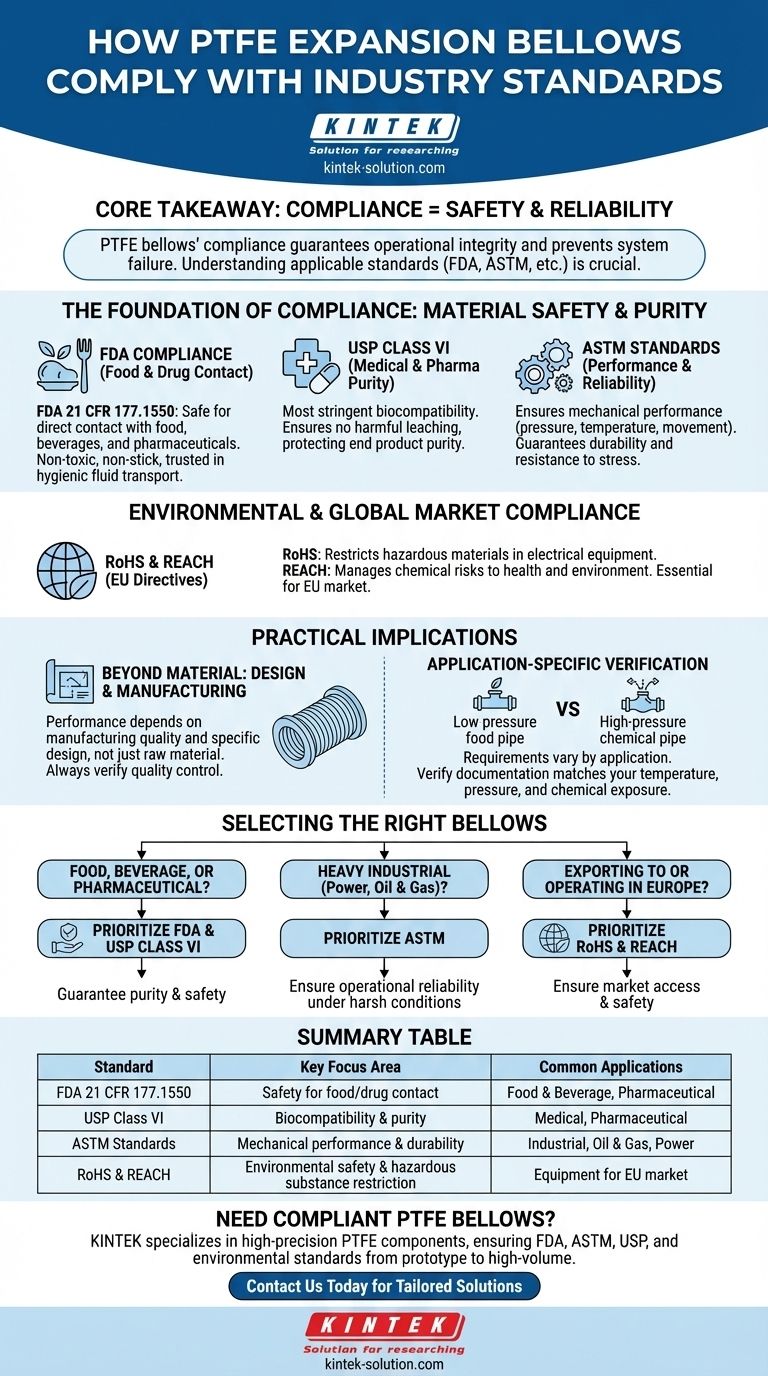

The core takeaway is that compliance for PTFE bellows is not just a technicality; it is a guarantee of safety and reliability. Understanding which standards apply to your specific industry—from FDA for food contact to ASTM for industrial durability—is crucial for ensuring operational integrity and preventing system failure.

The Foundation of Compliance: Material Safety and Purity

The suitability of PTFE expansion bellows for sensitive applications stems directly from the inherent properties of the Polytetrafluoroethylene material itself. Its chemical inertness and purity allow it to pass rigorous testing required by global regulatory bodies.

FDA Compliance for Food and Drug Contact

PTFE materials used in these bellows typically comply with FDA 21 CFR 177.1550. This standard certifies the material as safe for direct contact with food, beverages, and pharmaceuticals.

The non-toxic and non-stick surface of PTFE prevents residue buildup and contamination. This is why they are trusted in breweries, dairy processing plants, and pharmaceutical manufacturing to ensure hygienic fluid transport.

USP Class VI for Medical and Pharmaceutical Purity

For medical and pharmaceutical applications, compliance with USP (United States Pharmacopeia) Class VI is often required. This is the most stringent USP classification and involves rigorous biocompatibility testing.

This standard ensures that no harmful substances will leach from the material into the process fluid, protecting the purity and safety of the end product.

ASTM Standards for Performance and Reliability

ASTM (American Society for Testing and Materials) standards relate to the physical and mechanical properties of the bellows. Compliance ensures the component will perform reliably under specified conditions of pressure, temperature, and movement.

In demanding environments like power plants or oil and gas facilities, this compliance guarantees the bellow's durability and resistance to stress-induced cracks, directly impacting system stability and safety.

Environmental and Global Market Compliance

Beyond product safety, compliance with environmental regulations is critical for modern manufacturing and global trade.

Meeting RoHS and REACH Directives

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) are European Union directives.

RoHS restricts the use of specific hazardous materials in electrical and electronic equipment. REACH focuses on managing the risks posed by chemicals to human health and the environment. Compliance with these standards is essential for components used in equipment intended for the EU market.

Understanding the Practical Implications

Simply knowing a component is "compliant" is not enough. The context of its application determines which standards are most critical and what you must verify.

Beyond the Material: Design and Manufacturing Matter

While the raw PTFE material meets these standards, the final product's performance also depends on the manufacturing quality and the bellow's specific design.

Always ensure that the manufacturer's quality control processes validate the integrity of the finished component, not just the raw material.

The Importance of Application-Specific Verification

A bellow designed for a low-pressure syrup line in a food plant has different performance requirements than one handling corrosive chemicals in a high-pressure oil pipeline.

It is critical to verify that the bellow's compliance documentation matches the specific demands of your operating conditions—including temperature, pressure, and chemical exposure.

Selecting the Right Bellows for Your Application

Use these guidelines to prioritize the most relevant standards for your project.

- If your primary focus is food, beverage, or pharmaceutical production: Prioritize FDA and USP Class VI compliance to guarantee product purity and safety.

- If your primary focus is heavy industrial use (power, oil & gas): Prioritize ASTM compliance to ensure mechanical durability and operational reliability under harsh conditions.

- If your primary focus is exporting to or operating within Europe: Ensure the components meet RoHS and REACH directives for environmental safety and market access.

By aligning the bellow's certified standards with your specific operational needs, you ensure both regulatory compliance and long-term system integrity.

Summary Table:

| Standard | Key Focus Area | Common Applications |

|---|---|---|

| FDA 21 CFR 177.1550 | Safety for food/drug contact | Food & Beverage, Pharmaceutical |

| USP Class VI | Biocompatibility & purity | Medical, Pharmaceutical |

| ASTM Standards | Mechanical performance & durability | Industrial, Oil & Gas, Power |

| RoHS & REACH | Environmental safety & hazardous substance restriction | Equipment for EU market |

Need PTFE bellows that meet your industry's strictest standards? KINTEK specializes in manufacturing high-precision, compliant PTFE components—including seals, liners, labware, and custom expansion bellows—for semiconductor, medical, laboratory, and industrial applications. We ensure every part meets relevant FDA, ASTM, USP, and environmental standards, from prototype to high-volume production. Contact us today to discuss your requirements and receive a solution tailored to your compliance and performance needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability