From a purely financial standpoint, Nitrile (NBR) oil seals are significantly more affordable than Polytetrafluoroethylene (PTFE) seals. NBR's lower cost is due to its widespread availability and less complex manufacturing process. The higher price of PTFE is a direct reflection of its advanced material properties, which are necessary for demanding applications.

The choice between PTFE and NBR is not a simple matter of upfront cost. It's a strategic decision based on the total cost of ownership, where NBR offers immediate savings for standard applications, while PTFE's higher price is an investment in reliability for extreme operating conditions.

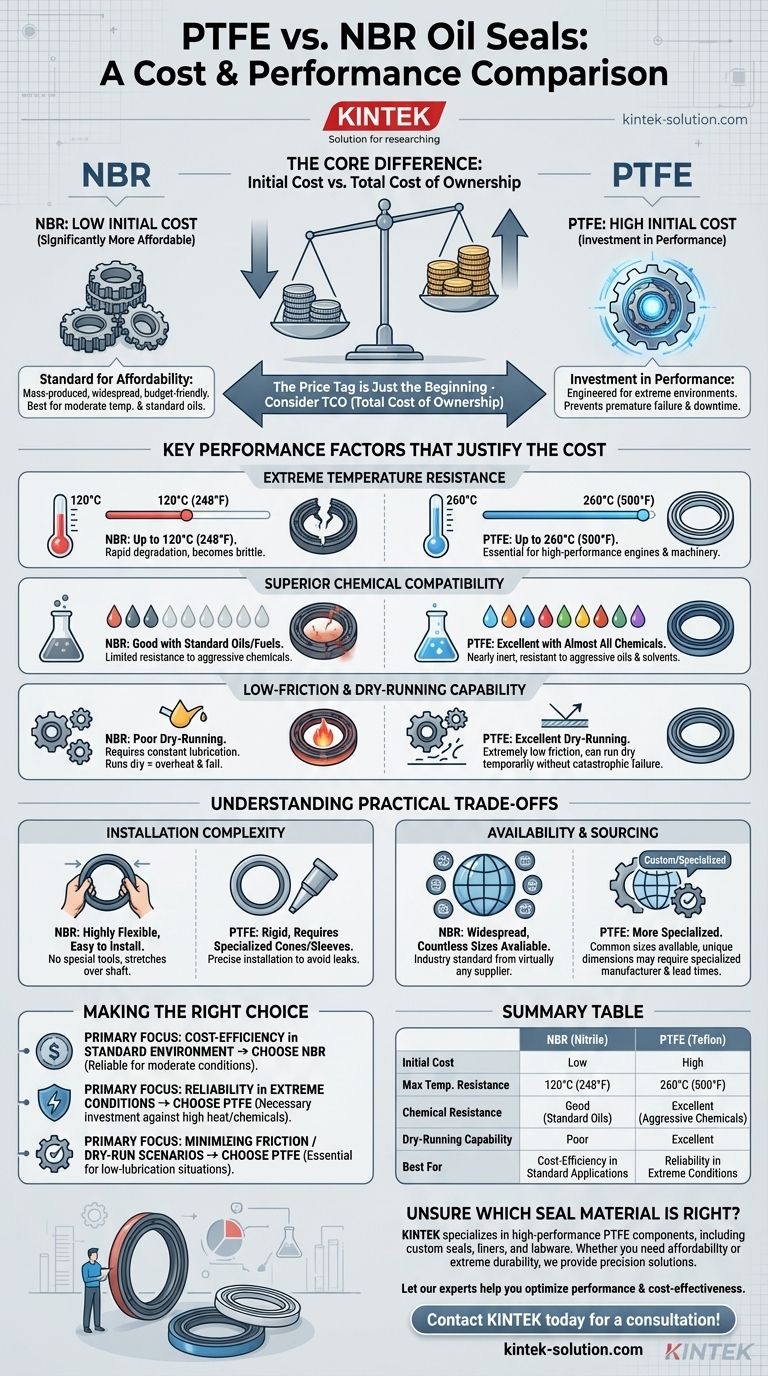

The Core Difference: Initial Cost vs. Total Cost of Ownership

The price tag of a seal is only the beginning of the story. The true cost is revealed over the component's service life, factoring in potential downtime, maintenance, and replacement expenses.

NBR (Nitrile): The Standard for Affordability

NBR is the go-to material for general-purpose sealing applications. It is mass-produced and widely available, making it the most budget-friendly option on the market.

Its cost-effectiveness makes it the default choice for environments with moderate temperatures and standard oils or fuels.

PTFE (Teflon): An Investment in Performance

PTFE seals are more expensive because they are engineered materials designed to survive where NBR would fail.

Think of the higher price not as a cost, but as insurance against premature failure in high-stress environments. This investment often prevents far more expensive damage and downtime later.

Key Performance Factors That Justify the Cost

The price difference is directly tied to the vast gap in performance capabilities between the two materials. You are paying for specific properties required to handle operational stress.

Extreme Temperature Resistance

PTFE can withstand continuous operating temperatures up to 260°C (500°F), making it essential for high-performance engines and industrial machinery.

In contrast, NBR's performance degrades rapidly above 120°C (248°F), at which point it becomes brittle and will fail.

Superior Chemical Compatibility

PTFE is nearly inert and resistant to almost all industrial chemicals, aggressive oils, and solvents. This makes it indispensable in chemical processing or applications with specialized synthetic lubricants.

NBR performs well with standard petroleum-based oils and fuels but has limited resistance to more aggressive chemicals, which can cause it to swell, soften, and break down.

Low-Friction and Dry-Running Capability

A key advantage of PTFE is its extremely low coefficient of friction. This allows it to run with minimal lubrication and even survive short periods of dry running without catastrophic failure.

NBR, being a flexible rubber, requires a constant film of lubrication. Running it dry, even for a moment, can cause it to overheat and be destroyed.

Understanding the Practical Trade-offs

Beyond performance, the physical nature of each material introduces important considerations for installation and maintenance.

Installation Complexity

NBR seals are highly flexible and forgiving, making them very easy to install. Their elasticity allows them to be stretched over a shaft without special tools.

PTFE seals are rigid and have no memory. They require careful, precise installation using specialized cones or sleeves to avoid damaging the sealing lip. An improper installation will cause an immediate leak.

Availability and Sourcing

As the industry standard, NBR seals are available in countless sizes from virtually any supplier.

PTFE seals are more specialized. While common sizes are available, unique dimensions or configurations may require sourcing from a specialized manufacturer and could have longer lead times.

Making the Right Choice for Your Application

The decision between NBR and PTFE hinges entirely on your specific operational demands and budget priorities.

- If your primary focus is cost-efficiency in a standard environment: NBR is the clear choice, offering reliable performance for moderate temperatures and common lubricants.

- If your primary focus is reliability in extreme conditions: The higher upfront cost of a PTFE seal is a necessary investment to prevent premature failure from high heat or aggressive chemicals.

- If your primary focus is minimizing friction or handling potential dry-run scenarios: PTFE is essential, as NBR requires constant lubrication to function correctly and avoid damage.

Choosing the right seal is about matching the material's capabilities to your application's demands, ensuring both performance and long-term value.

Summary Table:

| Feature | NBR (Nitrile) | PTFE (Teflon) |

|---|---|---|

| Initial Cost | Low | High |

| Max Temp. Resistance | 120°C (248°F) | 260°C (500°F) |

| Chemical Resistance | Good (Standard Oils) | Excellent (Aggressive Chemicals) |

| Dry-Running Capability | Poor | Excellent |

| Best For | Cost-Efficiency in Standard Applications | Reliability in Extreme Conditions |

Unsure which seal material is right for your application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom seals, liners, and labware. Whether you need the affordability of NBR for standard use or the extreme durability of PTFE for demanding environments in the semiconductor, medical, or industrial sectors, we provide precision solutions from prototypes to high-volume orders.

Let our experts help you optimize performance and cost-effectiveness. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers