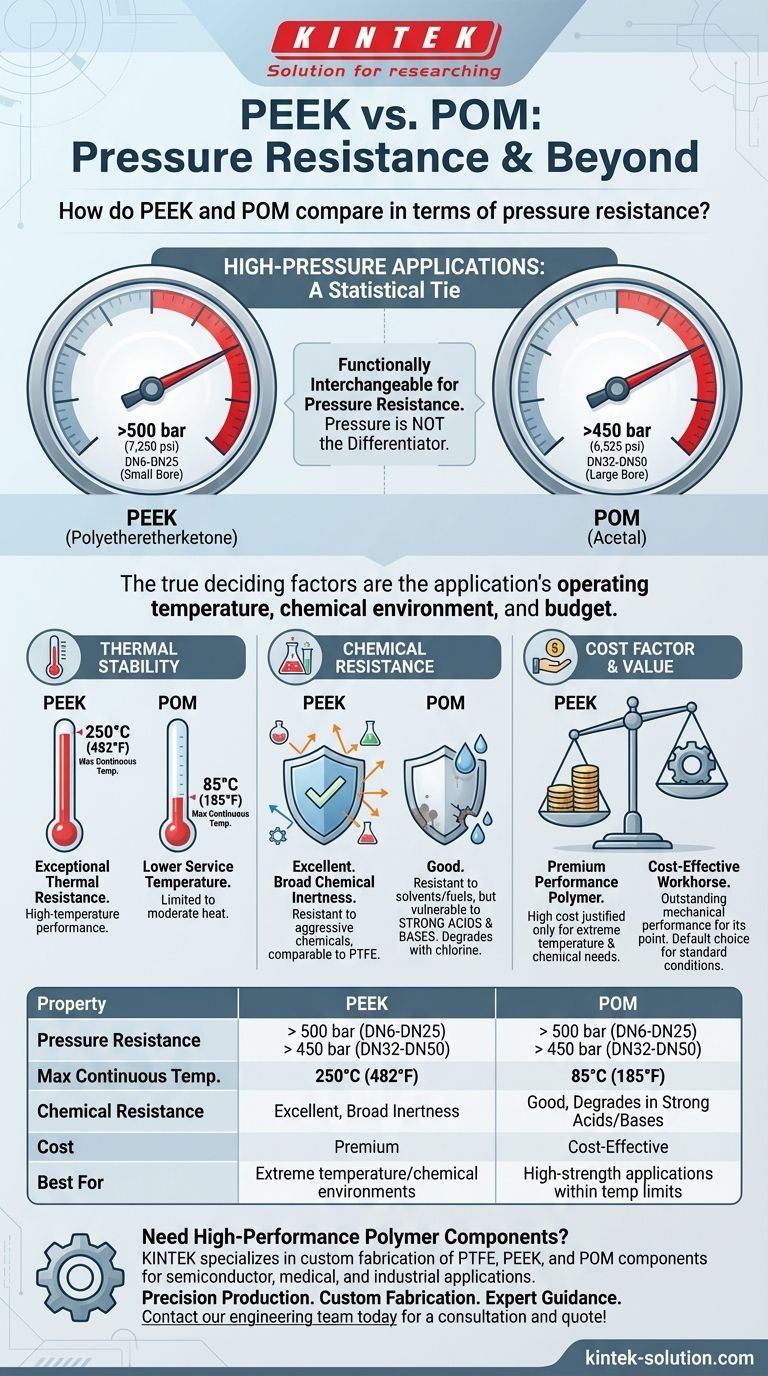

For high-pressure applications, PEEK and POM (Acetal) offer nearly identical pressure resistance. Both materials can reliably handle pressures of 500 bar or more in smaller bore sizes (DN6-DN25) and 450 bar or more in larger sizes (DN32-DN50), making them functionally interchangeable on this specific metric alone.

The choice between PEEK and POM is rarely about pressure resistance. The true deciding factors are the application's operating temperature, chemical environment, and budget.

A Direct Comparison of Pressure Handling

When evaluating materials for high-pressure systems, both PEEK and POM stand out as high-performance options, far exceeding the capabilities of materials like PTFE.

Capability in Small Bore Applications (DN6-DN25)

For smaller diameter piping and components, both PEEK and POM demonstrate exceptional strength. They are rated to withstand pressures exceeding 500 bar (7,250 psi), making them suitable for demanding hydraulic and processing systems.

Capability in Larger Bore Applications (DN32-DN50)

As the internal diameter increases, the total force on the material also increases. Even in these larger sizes, both polymers maintain robust performance, with a pressure rating of 450 bar (6,525 psi) or more.

The Key Insight: Pressure is Not the Differentiator

Because their pressure ratings are so similar, you cannot select the right material based on this factor alone. A deeper look at their other properties is necessary to understand where each one excels.

The Critical Differences Beyond Pressure

The true distinction between PEEK and POM emerges when you consider the complete operating environment. These differences are often far more important than their shared pressure capabilities.

Thermal Stability

PEEK (Polyetheretherketone) possesses exceptional thermal resistance. It can operate continuously at temperatures up to 250°C (482°F) without significant loss of its mechanical properties.

POM (Polyoxymethylene), often known as Acetal, has a much lower service temperature. It is generally limited to continuous use at around 85°C (185°F).

Chemical Resistance

PEEK is renowned for its broad chemical inertness, which is comparable to that of PTFE. It stands up to a vast range of aggressive organic and inorganic chemicals, even at elevated temperatures.

POM offers good resistance to many solvents and fuels but is vulnerable to strong acids and bases. Exposure to these substances, particularly chlorine, can cause it to degrade rapidly.

Mechanical Strength and Wear

Both materials are very strong, stiff, and exhibit excellent dimensional stability. However, PEEK maintains its strength and stiffness at much higher temperatures. It also has superior fatigue and wear resistance, especially in high-load, high-temperature dynamic applications.

POM has a naturally low coefficient of friction and high stiffness, making it an excellent choice for bearings and gears in moderate environments.

Understanding the Trade-offs: The Cost Factor

Your final decision will likely be constrained by budget, and this is where the two materials diverge dramatically.

PEEK: The Premium Performance Polymer

PEEK is one of the most expensive engineering thermoplastics on the market. Its cost is justified only in applications where its extreme temperature and chemical resistance are non-negotiable requirements.

POM: The Cost-Effective Workhorse

POM delivers outstanding mechanical performance for its price point. It is the go-to material for high-strength, high-stiffness applications where the environment is not thermally or chemically extreme.

Making the Right Choice for Your Application

To select the correct material, you must analyze the full scope of your project's demands beyond just pressure.

- If your primary focus is performance in high-temperature or aggressive chemical environments: PEEK is the only suitable choice due to its unmatched thermal and chemical stability.

- If your primary focus is mechanical strength and stiffness at a reasonable cost: POM provides exceptional value and is the default choice for applications within its temperature limits.

- If pressure resistance is truly the only critical factor: Both polymers are equally capable, making the more economical POM the logical starting point for your design.

Ultimately, your decision should be based on a complete picture of the operating environment, not a single performance metric.

Summary Table:

| Property | PEEK (Polyetheretherketone) | POM (Acetal / Polyoxymethylene) |

|---|---|---|

| Pressure Resistance | > 500 bar (DN6-DN25) > 450 bar (DN32-DN50) |

> 500 bar (DN6-DN25) > 450 bar (DN32-DN50) |

| Max Continuous Temp. | 250°C (482°F) | 85°C (185°F) |

| Chemical Resistance | Excellent, broad chemical inertness | Good, but degrades in strong acids/bases |

| Cost | Premium | Cost-Effective |

| Best For | Extreme temperature/chemical environments | High-strength applications within temp limits |

Need High-Performance PTFE or Engineered Polymer Components?

Choosing between PEEK and POM is just the start. For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, you need components manufactured with precision and expertise.

KINTEK specializes in the custom fabrication of high-quality PTFE components (seals, liners, labware) and other engineered polymers. We understand the critical balance of performance, durability, and cost.

We deliver value by:

- Precision Production: Ensuring every component meets exact specifications for reliable performance under pressure.

- Custom Fabrication: From initial prototypes to high-volume production runs, we tailor solutions to your unique needs.

- Expert Material Guidance: Helping you select the optimal material for your specific temperature, chemical, and mechanical requirements.

Let's discuss your project requirements. Contact our engineering team today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments