In the simplest terms, Polytetrafluoroethylene (PTFE) offers a dramatically lower coefficient of friction, making it one of the "slipperiest" materials known. Nylon provides good all-around wear resistance and superior mechanical strength, but with a significantly higher level of friction compared to PTFE. The correct choice depends entirely on the specific mechanical and environmental stresses of your application.

The decision between Nylon and PTFE is rarely about a single property. It is a strategic trade-off between PTFE's unparalleled low-friction performance and Nylon's cost-effective strength and durability.

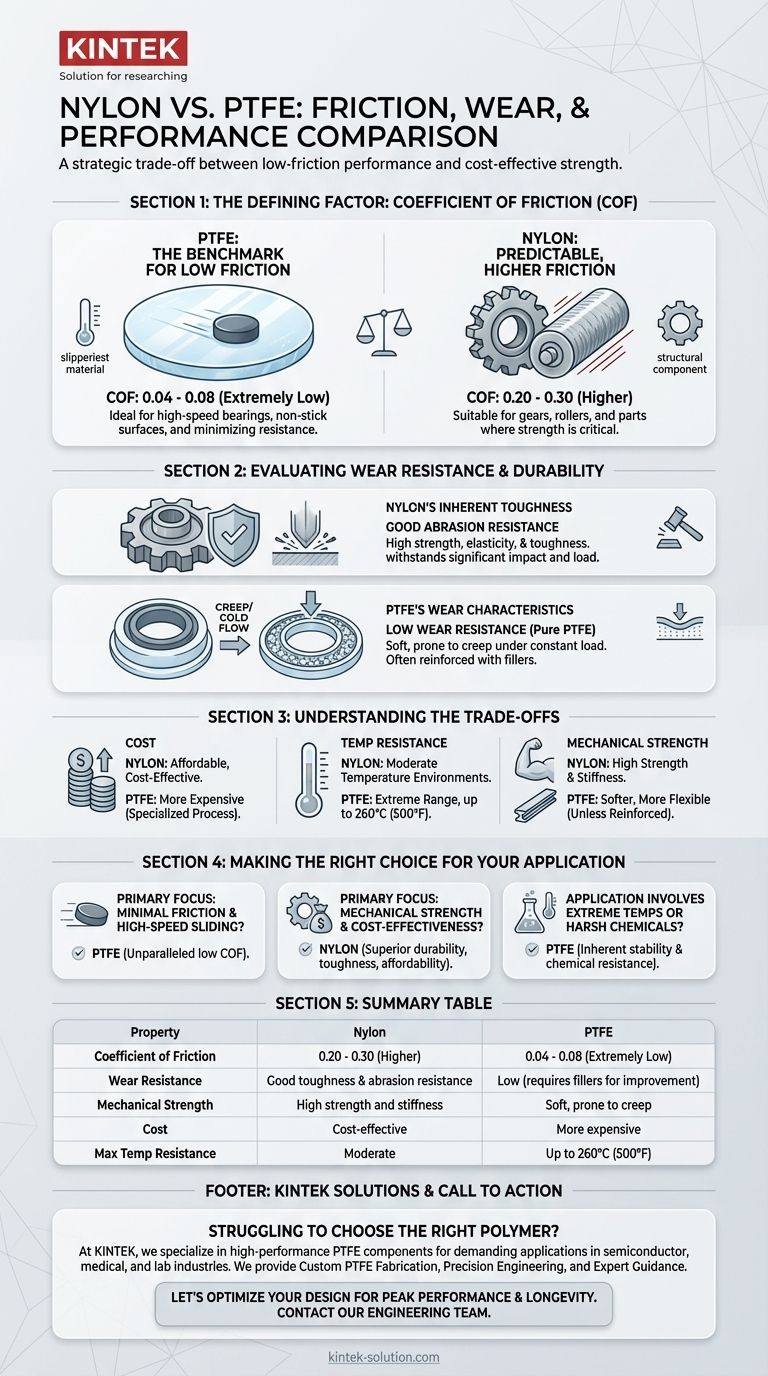

The Defining Factor: Coefficient of Friction

The most significant distinction between these two materials is how they behave under sliding contact. This property, the coefficient of friction (COF), dictates energy loss, heat generation, and overall efficiency in moving parts.

PTFE: The Benchmark for Low Friction

PTFE is the undisputed leader for low-friction applications. Its static and kinetic coefficients of friction are nearly identical and exceptionally low.

The dynamic COF for PTFE typically ranges from 0.04 to 0.08. This is significantly lower than almost any other solid engineering material, including lubricated steel.

This unique property makes PTFE the default choice for high-speed bearings, non-stick surfaces, and any component where minimizing resistance is the primary engineering goal.

Nylon: Predictable, Higher Friction

Nylon exhibits a much higher coefficient of friction, generally in the 0.20 to 0.30 range.

While not suitable for pure low-friction sliding, Nylon's properties make it an excellent material for gears, rollers, and structural components where its strength is the more critical factor. Its friction characteristics are well-understood and predictable.

Evaluating Wear Resistance and Durability

While friction is a critical metric, a material's ability to resist wear and deformation under load is equally important for longevity.

Nylon's Inherent Toughness

Nylon is well-regarded for its strength, elasticity, and overall toughness. This combination gives it good wear resistance, particularly in applications involving abrasion or high mechanical stress.

It can withstand significant impact and load without fracturing, making it ideal for components that need to be both durable and cost-effective.

PTFE's Wear Characteristics

Pure PTFE is a relatively soft material. While its slipperiness prevents abrasive wear, it can be susceptible to "creep" or cold flow, meaning it can deform over time when under a constant load.

For this reason, PTFE is often reinforced with fillers like glass or carbon to dramatically improve its wear resistance and mechanical stability while retaining its low-friction properties.

Understanding the Trade-offs

Choosing the right material requires a clear understanding of the compromises you are making beyond friction and wear.

Cost

Nylon is a significantly more affordable material, making it a common choice for cost-sensitive projects and high-volume production.

PTFE is a more expensive polymer due to its specialized manufacturing process and unique chemical properties.

Temperature Resistance

Nylon is well-suited for applications in moderate temperature environments.

PTFE excels in extreme conditions, maintaining its properties across a very wide temperature range, from cryogenic levels up to 260°C (500°F).

Mechanical Strength

Nylon is mechanically strong and stiff, capable of handling high loads and serving as a structural component.

PTFE is much softer and more flexible, which is not ideal for applications requiring high structural integrity unless it is mechanically contained or reinforced.

Making the Right Choice for Your Application

Your selection should be guided by the single most critical requirement of your design.

- If your primary focus is minimal friction and high-speed sliding: PTFE is the unparalleled choice due to its exceptionally low coefficient of friction.

- If your primary focus is mechanical strength and cost-effectiveness: Nylon offers a superior balance of durability, toughness, and affordability for gears and structural parts.

- If your application involves extreme temperatures or harsh chemicals: PTFE's inherent stability and chemical resistance make it the only viable option.

By aligning the material's core strengths with your application's primary demand, you ensure optimal performance and reliability.

Summary Table:

| Property | Nylon | PTFE |

|---|---|---|

| Coefficient of Friction | 0.20 - 0.30 (Higher) | 0.04 - 0.08 (Extremely Low) |

| Wear Resistance | Good toughness & abrasion resistance | Low (requires fillers for improvement) |

| Mechanical Strength | High strength and stiffness | Soft, prone to creep |

| Cost | Cost-effective | More expensive |

| Max Temp Resistance | Moderate | Up to 260°C (500°F) |

Struggling to choose the right polymer for your component?

At KINTEK, we specialize in high-performance PTFE components for the most demanding applications in the semiconductor, medical, and laboratory industries. Our expertise ensures you get the optimal material solution, balancing low friction, wear resistance, and mechanical properties.

We provide:

- Custom PTFE Fabrication: From prototypes to high-volume production of seals, liners, and labware.

- Precision Engineering: Components designed to meet your exact specifications for friction, temperature, and chemical resistance.

- Expert Guidance: Leverage our material science knowledge to select the perfect polymer for your unique needs.

Let's optimize your design for peak performance and longevity. Contact our engineering team today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers