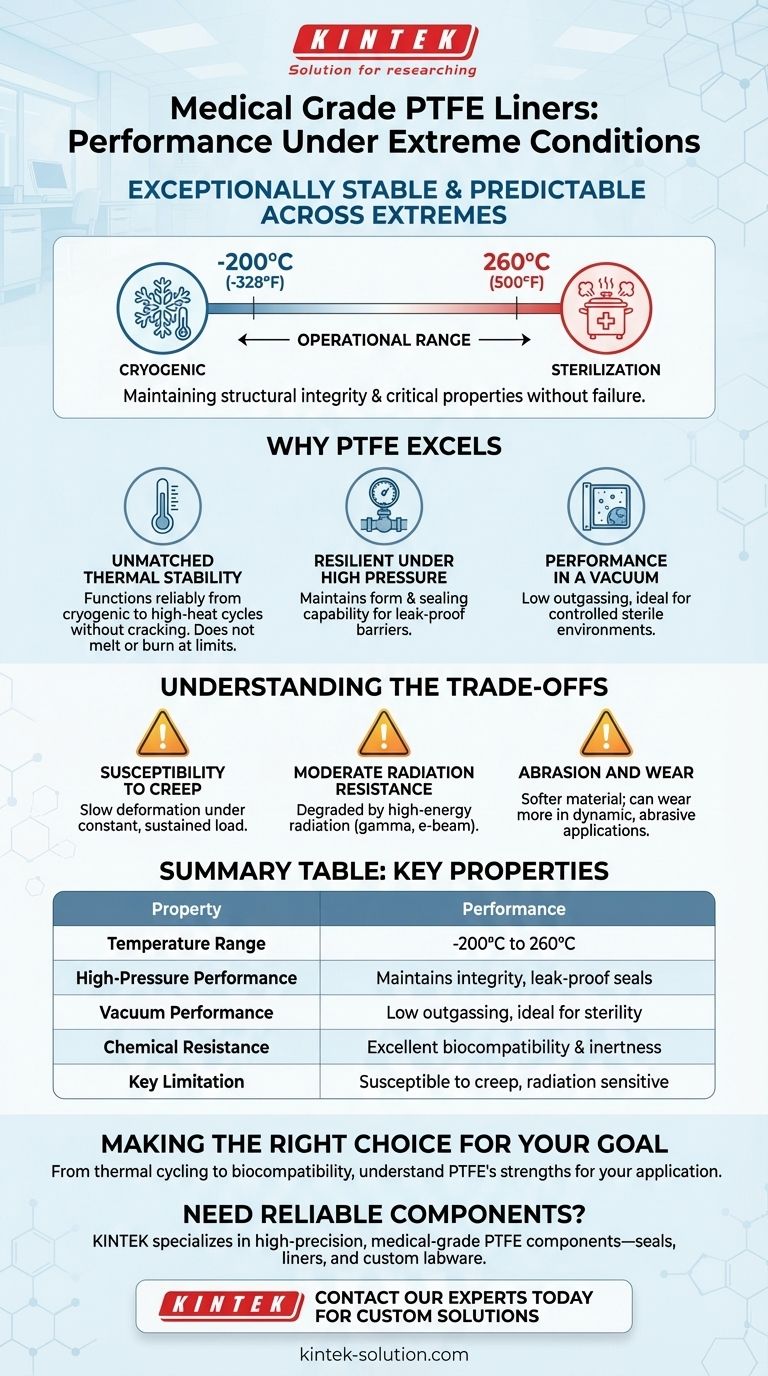

To put it directly, Medical Grade PTFE liners perform exceptionally well under extreme conditions. They maintain their structural integrity and critical properties across a vast temperature range, from cryogenic lows of -200°C (-328°F) to high-heat sterilization temperatures of 260°C (500°F), all while withstanding high-pressure fluid and gas environments without failure.

The true value of Medical Grade PTFE is not just its tolerance for extreme conditions, but its remarkable stability and predictability across that entire operational range. This consistency ensures reliable, failure-proof performance in the most demanding medical applications where safety is non-negotiable.

Why PTFE Excels in Extreme Environments

The material's molecular structure gives it a unique combination of properties. This makes it a default choice for components that will be exposed to punishing temperatures, pressures, or chemical agents.

Unmatched Thermal Stability

Medical Grade PTFE offers one of the widest operating temperature ranges of any polymer. It functions reliably from -200°C to 260°C (-328°F to 500°F).

This means it is perfectly suited for applications involving cryogenic processes as well as high-temperature sterilization cycles, such as in pharmaceutical production, without cracking or losing functionality.

Unlike many other polymers, PTFE does not melt or burn at its upper temperature limits, providing a critical margin of safety.

Resilient Under High Pressure

PTFE maintains its form and sealing capability even when containing pressurized fluids or gases.

This structural integrity is essential in medical devices where a liner must ensure a consistent and leak-proof barrier between mating surfaces, guaranteeing the purity and containment of the media being transferred.

Performance in a Vacuum

PTFE’s inherent stability allows it to perform reliably even in the vacuum of space.

In a medical context, this translates to excellent performance in controlled or sterile environments where outgassing (the release of trapped gasses) could be a source of contamination.

Understanding the Trade-offs

No material is without its limitations. Objectively evaluating PTFE requires understanding where it may not be the optimal choice. These trade-offs are well-understood and can be engineered around, but they must be considered.

Susceptibility to Creep

Under a constant, sustained mechanical load, PTFE can be subject to "creep" or "cold flow." This means the material can slowly deform over time.

For applications involving high static loads or precise, long-term dimensional stability, this characteristic must be accounted for in the design phase.

Moderate Radiation Resistance

While chemically inert, PTFE can be degraded by high-energy radiation, such as gamma or e-beam, which are common methods for sterilizing single-use medical devices.

If this sterilization method is required, the specific grade of PTFE and the radiation dosage must be carefully evaluated to ensure material integrity is not compromised.

Abrasion and Wear

Standard PTFE is a relatively soft material. In dynamic applications with significant friction or abrasive contact, it can wear more quickly than harder polymers.

This can often be mitigated by using filled grades of PTFE, which incorporate materials like glass fiber or carbon to enhance wear resistance, though this may impact other properties.

Making the Right Choice for Your Goal

Your specific application will determine if PTFE’s strengths align with your needs.

- If your primary focus is thermal cycling: PTFE's ability to withstand both high-heat sterilization and extreme cold without degradation is its key advantage.

- If your primary focus is high-pressure fluid or gas delivery: Its proven structural integrity and reliable sealing performance ensure containment and prevent leaks.

- If your primary focus is biocompatibility and sterility: PTFE’s chemical inertness and low outgassing make it an exceptionally clean and safe material for critical medical contact.

By understanding both its unparalleled strengths and its known limitations, you can confidently specify Medical Grade PTFE for applications where performance cannot be compromised.

Summary Table:

| Property | Performance Under Extreme Conditions |

|---|---|

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| High-Pressure Performance | Maintains structural integrity and leak-proof seals |

| Vacuum Performance | Low outgassing, ideal for sterile environments |

| Chemical Resistance | Excellent biocompatibility and inertness |

| Key Limitation | Susceptible to creep under sustained load; moderate radiation resistance |

Need a reliable PTFE component for your most demanding applications?

At KINTEK, we specialize in manufacturing high-precision, medical-grade PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and laboratory industries. Our expertise ensures your components perform predictably and safely under extreme conditions, from cryogenic processes to high-temperature sterilization.

We offer custom fabrication from prototypes to high-volume orders, prioritizing the precision and material integrity critical to your success.

Contact our experts today to discuss your specific requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech