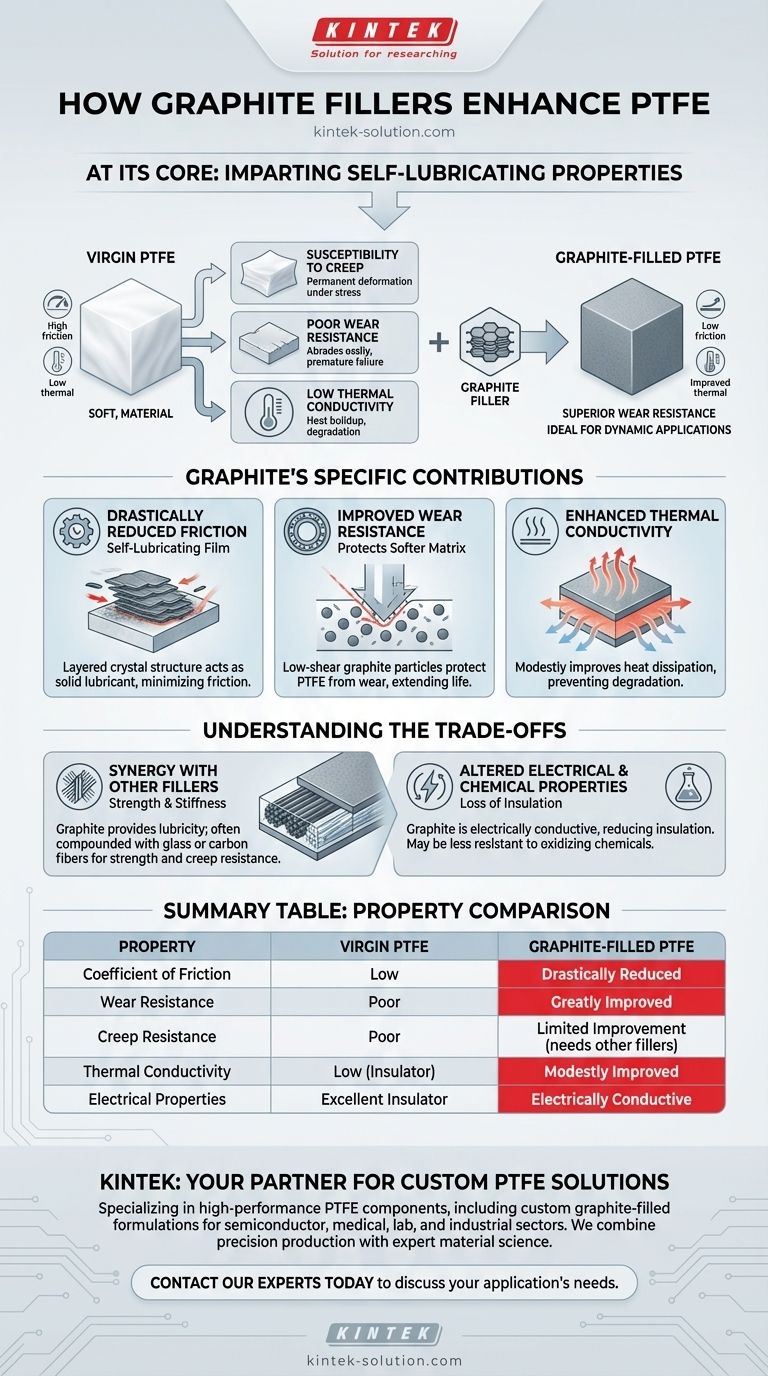

At its core, graphite enhances Polytetrafluoroethylene (PTFE) by imparting self-lubricating properties that significantly reduce its coefficient of friction. This addition transforms the material, creating a composite with superior wear resistance, making it ideal for dynamic applications where surfaces are in constant contact.

The fundamental purpose of adding fillers to PTFE is to overcome its inherent weaknesses, such as poor wear resistance and deformation under load. Graphite is a specialized filler that excels at providing lubricity, turning standard PTFE into a high-performance bearing and seal material.

Why Virgin PTFE Needs Enhancement

Unfilled, or "virgin," PTFE is a remarkable polymer known for its extreme chemical inertness and low friction. However, it has significant mechanical limitations that restrict its use in demanding engineering applications.

Susceptibility to Creep

Virgin PTFE is mechanically soft and prone to creep, which is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. This makes it unsuitable for components that must hold their shape under a constant load.

Poor Wear Resistance

Despite its low friction, pure PTFE abrades very easily. In dynamic applications like seals or bearings, it wears down quickly, leading to premature failure. Research shows that adding fillers can improve abrasion resistance by a factor of nearly 1000.

Low Thermal Conductivity

PTFE is an excellent thermal insulator. While useful in some cases, this property is a disadvantage in high-speed applications where friction generates heat. The inability to dissipate this heat can cause the material to degrade and fail.

Graphite's Specific Contributions

Graphite is added to PTFE to directly address these weaknesses, often in combination with other fillers like glass or carbon to achieve a balance of properties.

Drastically Reduced Friction

The primary role of graphite is to act as a solid lubricant. Its layered, flaky crystal structure allows planes to shear off and coat the mating surface, creating a highly effective self-lubricating film that minimizes friction between moving parts.

Improved Wear Resistance

By lowering friction, graphite directly enhances wear resistance. The low-shear nature of the graphite particles protects the softer PTFE matrix from abrasion, extending the service life of components like piston rings and slide bearings.

Enhanced Thermal Conductivity

While not as effective as metallic fillers, graphite modestly improves the thermal conductivity of the PTFE composite. This helps dissipate localized heat generated at wear surfaces, preventing thermal expansion and material degradation.

Understanding the Trade-offs

Adding any filler, including graphite, is an engineering compromise. Enhancing one property often comes at the expense of another.

Synergy with Other Fillers

Graphite provides excellent lubricity but offers little improvement in creep resistance. For this reason, it is almost always compounded with carbon or glass fibers. These structural fillers provide the stiffness and compressive strength that graphite lacks, creating a robust material that is both strong and low-friction.

Altered Electrical Properties

Virgin PTFE is one of the best electrical insulators available. Graphite, however, is electrically conductive. Adding it to PTFE significantly reduces the material's insulating properties, making it unsuitable for applications requiring high dielectric strength.

Chemical Resistance Considerations

While the PTFE matrix remains highly inert, graphite is not. The resulting composite may be less resistant to highly oxidizing chemicals compared to virgin PTFE. The application's chemical environment must always be considered.

Making the Right Choice for Your Application

Selecting the correct PTFE formulation depends entirely on the mechanical, thermal, and electrical demands of your specific use case.

- If your primary focus is the lowest possible friction in a dynamic seal: A graphite and carbon-filled PTFE blend is an ideal choice.

- If your primary focus is high load capacity and creep resistance: A glass or carbon-filled PTFE is necessary, with graphite added only if lubricity is also a key requirement.

- If your primary focus is electrical insulation: You must avoid graphite and other conductive fillers, opting for virgin PTFE or one filled with glass.

Ultimately, understanding how fillers like graphite modify PTFE's base properties empowers you to select a material precisely engineered for your specific challenge.

Summary Table:

| Property | Virgin PTFE | Graphite-Filled PTFE |

|---|---|---|

| Coefficient of Friction | Low | Drastically Reduced |

| Wear Resistance | Poor | Greatly Improved |

| Creep Resistance | Poor | Limited Improvement (needs other fillers) |

| Thermal Conductivity | Low (Insulator) | Modestly Improved |

| Electrical Properties | Excellent Insulator | Electrically Conductive |

Need a PTFE component engineered for your specific challenge?

KINTEK specializes in manufacturing high-performance PTFE components, including custom graphite-filled formulations, for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with expert material science to deliver solutions that offer superior self-lubrication, wear resistance, and longevity—from prototypes to high-volume orders.

Contact our experts today to discuss how our custom PTFE solutions can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications