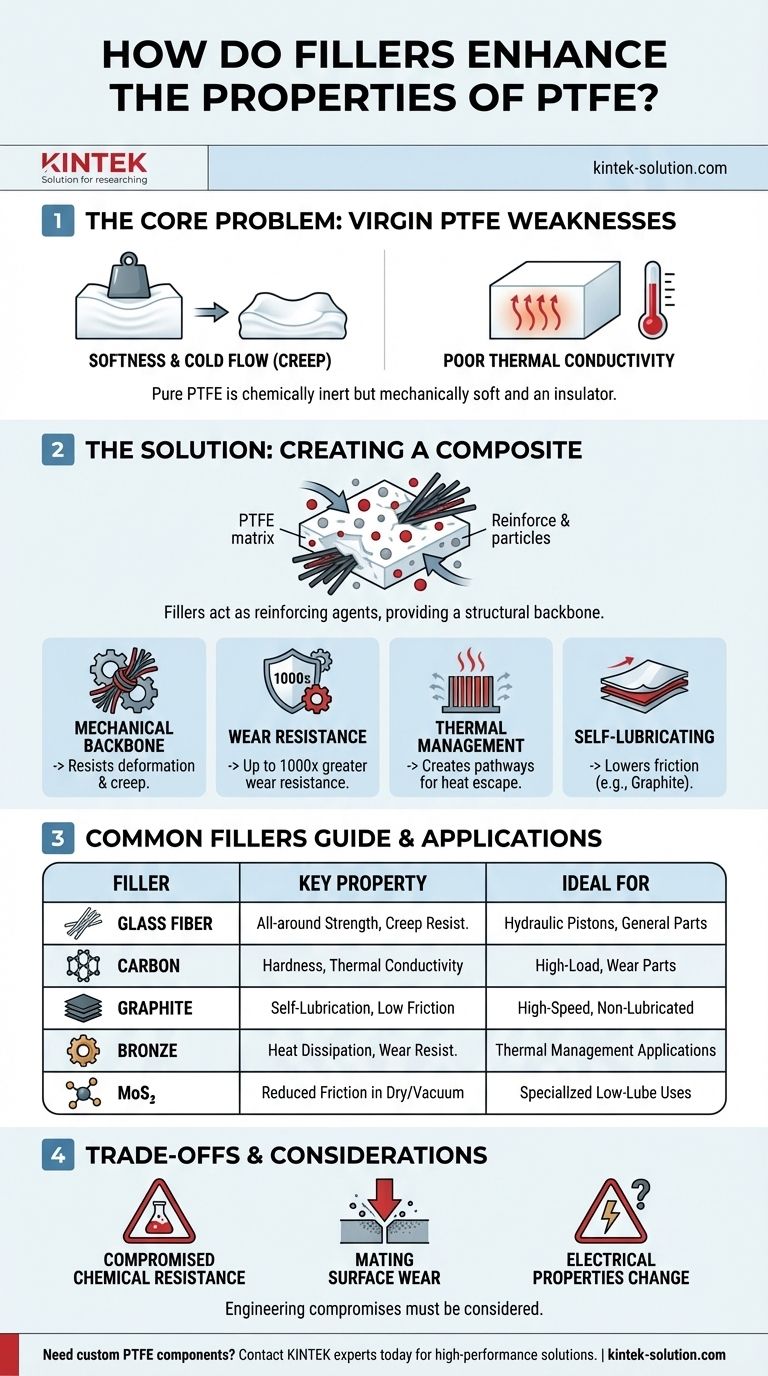

In short, fillers are added to Polytetrafluoroethylene (PTFE) to overcome its inherent mechanical weaknesses. While pure, or "virgin," PTFE is prized for its extremely low friction and chemical inertness, it is mechanically soft and deforms easily under load. Fillers act as a reinforcing agent, dramatically improving properties like wear resistance, compressive strength, and thermal conductivity.

The core problem with pure PTFE is its tendency to "creep" or deform under pressure, a phenomenon known as cold flow. Fillers provide a structural backbone within the soft PTFE matrix, creating a composite material that retains low friction while gaining the mechanical integrity needed for demanding applications.

The Fundamental Weakness of Unfilled PTFE

To understand why fillers are essential, we must first appreciate the limitations of pure PTFE. It excels in specific areas but fails in others without modification.

Softness and Cold Flow (Creep)

Pure PTFE is a relatively soft material. When subjected to a constant load, especially at elevated temperatures, it will slowly deform and "flow" away from the pressure point. This makes it unsuitable for high-load bearings or structural components.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. In dynamic applications like seals or bearings, friction generates heat. Because pure PTFE cannot effectively dissipate this heat, temperatures can build up, accelerating wear and creep, and potentially leading to component failure.

How Fillers Engineer a Solution

Adding filler materials creates a composite that leverages the best of both worlds: the low friction of PTFE and the physical strength of the filler.

Providing a Mechanical Backbone

Fillers like glass fiber and carbon are much more rigid than PTFE. Dispersed throughout the material, they form a supportive matrix that resists deformation and significantly reduces creep, sometimes by a factor of two or more.

Enhancing Wear and Abrasion Resistance

The addition of hard filler particles drastically improves PTFE's ability to resist abrasion. Research shows that filled PTFE can have up to 1000 times greater wear resistance than its unfilled counterpart, making it suitable for dynamic seals and bearings.

Improving Thermal Management

Fillers such as bronze and graphite are far more thermally conductive than PTFE. They create a pathway for heat to escape from friction-heavy surfaces, preventing thermal buildup and maintaining the material's stability at higher speeds and loads.

Adding Self-Lubricating Properties

While PTFE is already slick, graphite takes this a step further. Graphite has a flaky, layered structure that shears easily, acting as a dry lubricant. This results in an extremely low coefficient of friction, ideal for non-lubricated or high-speed applications.

A Guide to Common Filler Materials

The choice of filler directly dictates the final properties of the PTFE compound. Each one is selected to solve a specific engineering challenge.

Glass Fiber

This is the most common and versatile filler. It provides an excellent all-around improvement in compressive strength, creep resistance, and wear resistance. It's a cost-effective choice for components like hydraulic piston rings.

Carbon

Carbon enhances hardness, compressive strength, and wear resistance. It also provides good thermal conductivity and is lighter than many other fillers. It is often combined with graphite.

Graphite

Graphite is primarily used for its self-lubricating properties, which lower the coefficient of friction and improve wear characteristics, especially in high-speed applications. It is often blended with carbon or glass.

Bronze

Bronze offers excellent wear resistance and high thermal conductivity, making it a good choice for applications that need to dissipate heat quickly. It also provides higher compressive strength and creep resistance.

Molybdenum Disulfide (MoS₂)

Often used in conjunction with other fillers, MoS₂ improves hardness and reduces friction, performing particularly well in dry or vacuum environments.

Understanding the Trade-offs

Adding fillers is not a universal upgrade. It involves a series of engineering compromises that must be considered for any application.

Compromised Chemical Resistance

The primary trade-off is a reduction in chemical inertness. Fillers like glass can be attacked by strong alkalis and hydrofluoric acid, while bronze is susceptible to corrosion. Pure PTFE remains the superior choice for extremely corrosive environments.

Mating Surface Wear

A harder, filled PTFE compound can be more abrasive to the surface it runs against. A carbon-filled seal, for example, may cause more wear on a soft aluminum or brass shaft than an unfilled one would. The hardness of both surfaces must be considered.

Electrical Properties

While pure PTFE is an exceptional electrical insulator, the addition of conductive fillers like carbon or bronze will change these properties. This is a critical consideration for any electrical or electronic application.

Making the Right Choice for Your Application

Selecting the correct filled PTFE compound requires matching the material's strengths to your primary operational goal.

- If your primary focus is general-purpose wear resistance and strength: Glass-filled PTFE is the most common and cost-effective solution.

- If your primary focus is low friction in high-speed or non-lubricated systems: Graphite or carbon-graphite-filled PTFE provides superior self-lubricating properties.

- If your primary focus is maximum compressive strength and creep resistance under heavy loads: Carbon-filled or bronze-filled PTFE are excellent choices.

- If your primary focus is dissipating heat from a dynamic system: Bronze-filled PTFE offers the best thermal conductivity.

By understanding the role of fillers, you can specify a PTFE compound precisely engineered to meet the mechanical demands of your application.

Summary Table:

| Filler Material | Key Property Enhancement | Ideal For |

|---|---|---|

| Glass Fiber | All-around strength & wear resistance | Hydraulic piston rings, general components |

| Carbon | High hardness & thermal conductivity | High-load applications, wear parts |

| Graphite | Superior self-lubrication & low friction | High-speed, non-lubricated systems |

| Bronze | Excellent heat dissipation & wear resistance | Applications requiring thermal management |

| Molybdenum Disulfide (MoS₂) | Reduced friction in dry/vacuum environments | Specialized, low-lubrication uses |

Need a PTFE component engineered for your specific application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from custom seals and liners to labware and more. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you select the right filled PTFE compound to maximize wear resistance, compressive strength, and thermal performance.

Let us provide you with precision parts, from prototypes to high-volume orders, tailored to your needs.

Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments