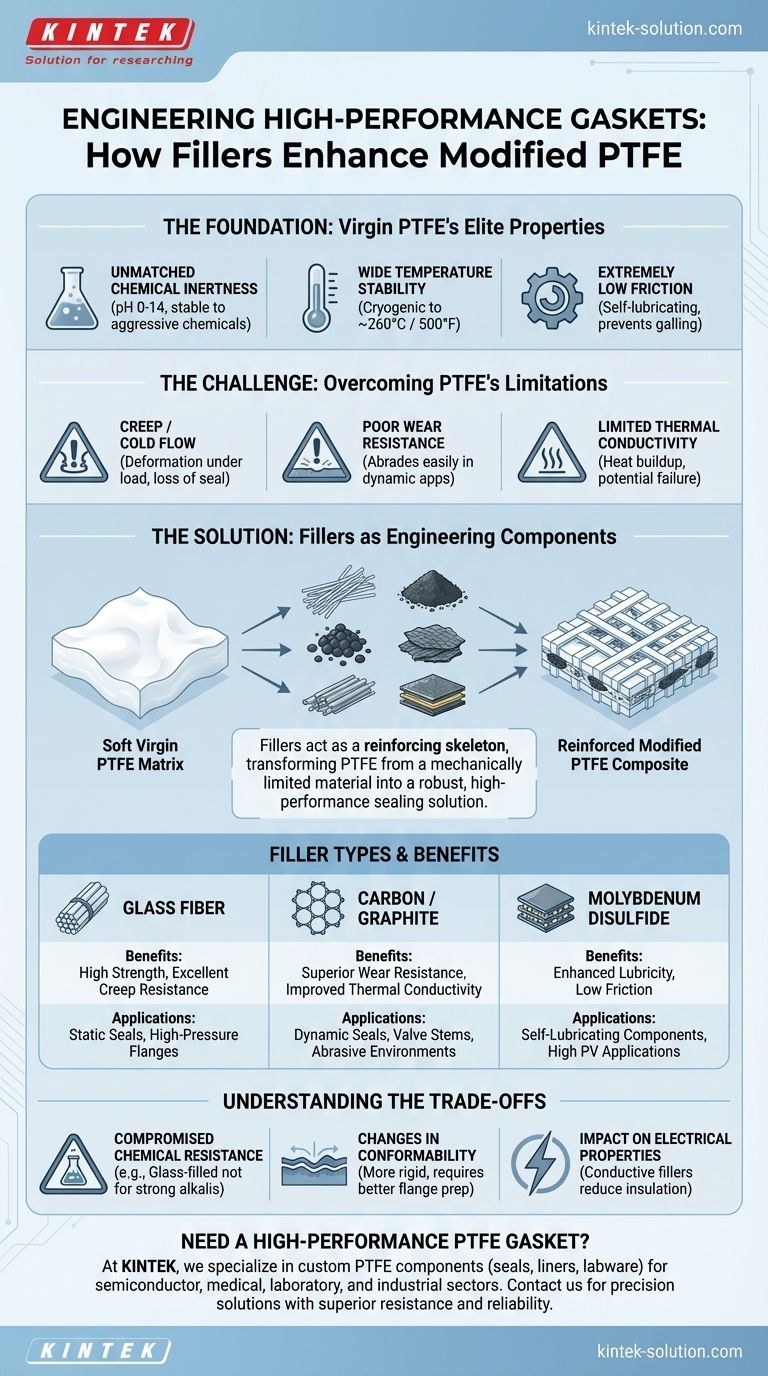

In essence, fillers are added to Polytetrafluoroethylene (PTFE) to fundamentally enhance its physical properties. While virgin PTFE is an exceptional material for chemical resistance and low-friction applications, it has inherent mechanical weaknesses. Fillers like glass fiber, carbon, and graphite are integrated into the PTFE matrix to significantly improve its strength, wear resistance, and resistance to deformation under load.

The core purpose of modifying PTFE with fillers is to overcome its natural softness and tendency to deform, a phenomenon known as "creep." This transforms it from an excellent but mechanically limited material into a robust, high-performance sealing solution for demanding industrial applications.

The Foundation: Why PTFE is an Elite Sealing Material

To understand the role of fillers, we must first appreciate the exceptional baseline properties of virgin PTFE. Its unique molecular structure makes it one of the most versatile sealing materials available.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It remains stable across the entire pH range (0–14), making it suitable for sealing even the most aggressive acids, bases, and solvents.

Wide Temperature Stability

PTFE performs reliably in extreme temperature ranges, from cryogenic levels up to approximately 260°C (500°F). This allows it to be specified for both high-heat and deep-freeze processes.

Extremely Low Friction

Known for its non-stick surface, PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property reduces torque requirements and prevents galling in dynamic or rotating applications.

The Challenge: Overcoming PTFE's Inherent Limitations

Despite its elite chemical and thermal properties, virgin PTFE is a relatively soft material. This presents critical limitations in applications involving high pressure, mechanical stress, or abrasive conditions.

The Problem of "Creep" or Cold Flow

When subjected to a constant compressive load, such as in a bolted flange, virgin PTFE has a tendency to slowly deform or "flow" out of the seal. This loss of gasket thickness can lead to a reduction in bolt load and eventual leakage.

Poor Wear Resistance

The softness and low friction of PTFE also mean it abrades easily. In dynamic sealing applications or environments with particulate matter, virgin PTFE gaskets can wear out quickly, compromising the seal.

Limited Thermal Conductivity

PTFE is an excellent thermal insulator. While often a benefit, this can be a drawback in high-speed applications where heat needs to be dissipated away from the sealing surface to prevent failure.

How Fillers Engineer a Superior Gasket

Fillers are not simply additives; they are engineering components that create a composite material with specifically targeted properties. They act as a reinforcing skeleton within the soft PTFE matrix.

Enhancing Mechanical Strength and Rigidity

Fillers like glass fiber and carbon fiber add significant structural integrity. They drastically reduce the material's tendency to creep under pressure, ensuring the gasket maintains its sealing force over time in high-pressure systems.

Improving Wear and Abrasion Resistance

Harder filler materials like graphite, carbon, and molybdenum disulfide significantly increase the gasket's durability. They create a tougher sealing surface that can withstand abrasive media and the friction of dynamic applications.

Boosting PV (Pressure-Velocity) Value

By improving both wear resistance and thermal conductivity (especially with graphite and carbon), fillers increase the gasket's PV rating. This value represents the material's ability to handle high pressures and high surface velocities simultaneously without failing.

Understanding the Trade-offs

Modifying PTFE is an exercise in engineering trade-offs. While fillers solve key mechanical problems, they can alter some of the material's original properties.

Compromised Chemical Resistance

The primary trade-off is a potential reduction in chemical inertness. For example, glass-filled PTFE is not suitable for strong alkalis or hydrofluoric acid, which can attack the glass fibers themselves.

Changes in Sealing Conformability

A more rigid, filled PTFE gasket may not conform as easily to scratched or uneven flange surfaces as a softer, virgin PTFE gasket. Proper surface preparation becomes more critical.

Impact on Electrical Properties

While virgin PTFE is an excellent electrical insulator, the addition of conductive fillers like carbon or graphite will change its electrical properties. This must be considered in applications where electrical isolation is required.

Making the Right Choice for Your Application

Selecting the correct gasket material depends entirely on the demands of your specific service environment.

- If your primary focus is ultimate chemical purity and inertness: Virgin PTFE remains the undisputed choice for applications in pharmaceuticals, food processing, or for sealing the most aggressive chemicals where mechanical stress is low.

- If your primary focus is high-pressure service and creep resistance: Glass-filled PTFE is often the standard, providing excellent mechanical stability for static seals like pipe flanges in chemical plants.

- If your primary focus is dynamic sealing and wear resistance: Carbon or graphite-filled PTFE provides the low friction and high durability needed for rotating shafts, valve stems, and other moving components.

Understanding these modifications allows you to specify a gasket that is not just suitable, but perfectly engineered for its task.

Summary Table:

| Filler Type | Key Benefits | Common Applications |

|---|---|---|

| Glass Fiber | High strength, excellent creep resistance | Static seals, high-pressure flanges |

| Carbon/Graphite | Superior wear resistance, improved thermal conductivity | Dynamic seals, valve stems, abrasive environments |

| Molybdenum Disulfide | Enhanced lubricity, low friction | Self-lubricating components, high PV applications |

Need a high-performance PTFE gasket engineered for your specific application? At KINTEK, we specialize in manufacturing custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services ensure you get a solution that delivers superior chemical resistance, mechanical strength, and long-term reliability. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support