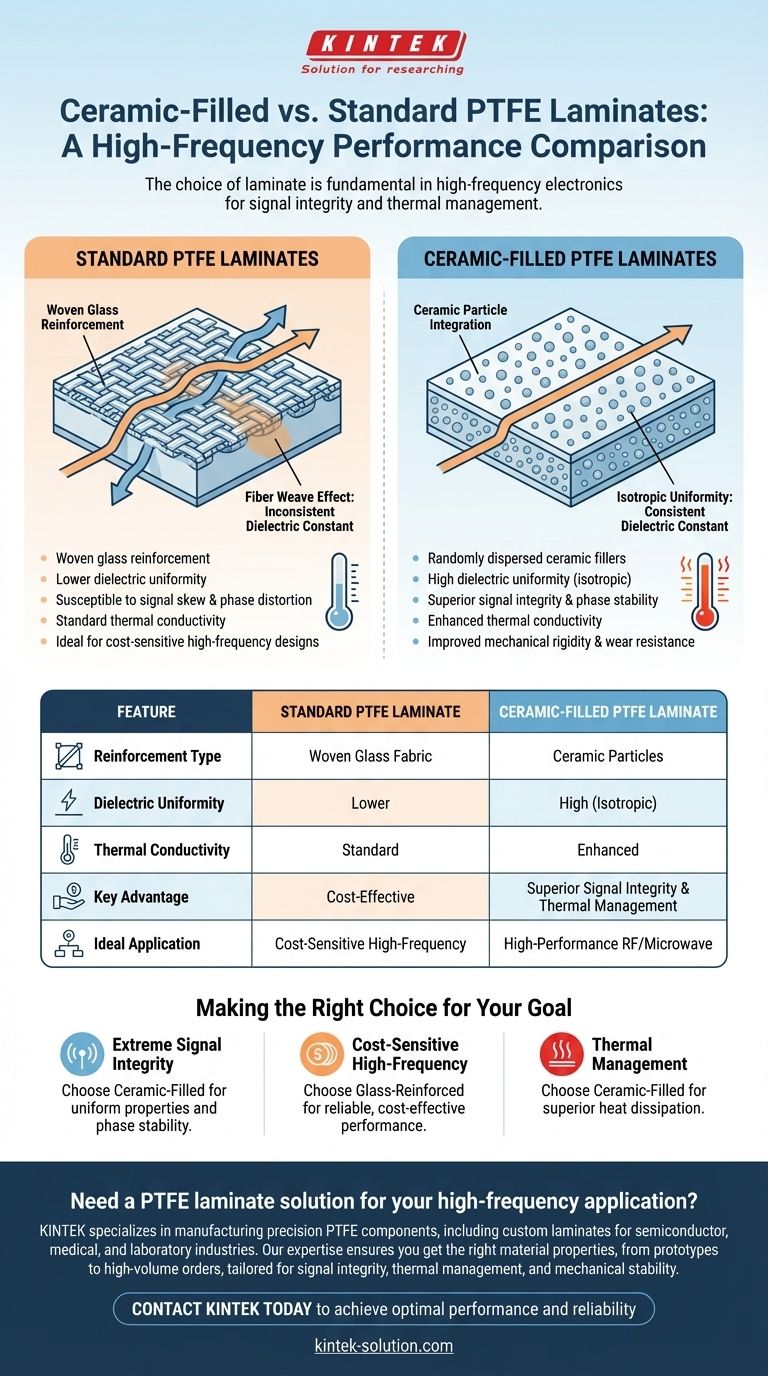

In high-frequency electronics, the choice of laminate is fundamental. Ceramic-filled Polytetrafluoroethylene (PTFE) laminates are a specialized evolution of standard PTFE-based materials. They integrate microscopic ceramic particles into the PTFE matrix to significantly improve thermal conductivity and mechanical rigidity. Most critically, this addition provides uniform electrical properties, which standard glass-reinforced PTFE can struggle to achieve at very high frequencies.

While both materials leverage PTFE's excellent electrical properties, the choice of filler is the critical differentiator. Ceramic-filled laminates typically replace woven glass reinforcement to eliminate the 'fiber weave effect,' resulting in superior signal integrity and thermal management for demanding RF and microwave applications.

The Core Problem with Standard Reinforcements

To understand the value of ceramic fillers, we must first understand why PTFE needs reinforcement at all and the limitations of the most common method.

PTFE's Need for Reinforcement

Pure PTFE is an exceptional insulator with a very low dielectric constant (Dk) and loss tangent, making it ideal for high-frequency signals.

However, pure PTFE is mechanically soft and has a high coefficient of thermal expansion. For use in a rigid Printed Circuit Board (PCB), it requires a reinforcing material, which is most commonly woven glass fabric.

The "Fiber Weave Effect" Explained

Woven glass provides the necessary rigidity, but its fibrous structure creates microscopic inconsistencies in the laminate.

The signal path on a PCB will cross over areas with more glass fiber (higher Dk) and areas with more PTFE resin (lower Dk). This inconsistent dielectric constant can cause signal skew and phase distortions, which become significant problems in high-speed digital and RF/microwave systems.

How Ceramic Fillers Provide a Superior Solution

Ceramic-filled laminates solve the problems created by woven glass by using a different approach to reinforcement. The ceramic particles are distributed evenly throughout the PTFE.

Isotropic and Uniform Electrical Performance

Instead of a structured weave, the randomly dispersed ceramic particles create a material that is isotropic, meaning its electrical properties are the same in every direction.

This uniformity eliminates the fiber weave effect. It ensures a consistent dielectric constant across the entire board, leading to predictable signal behavior, minimal skew, and stable phase response—all critical for high-fidelity systems.

Enhanced Thermal Conductivity

Ceramics are generally better thermal conductors than glass fibers or PTFE resin.

Integrating ceramic particles into the laminate creates a more efficient pathway for heat to dissipate away from active components like power amplifiers. This improved thermal management increases component reliability and performance.

Improved Mechanical Stability and Strength

The ceramic fillers add significant rigidity and dimensional stability to the PTFE. This results in a mechanically robust laminate with improved wear resistance compared to many standard glass-reinforced options.

Understanding the Trade-offs

While ceramic-filled laminates offer clear advantages, there are practical considerations to keep in mind.

Cost Considerations

Ceramic-filled materials are often more expensive than their glass-reinforced counterparts. However, for applications where their specific benefits are required, they become cost-effective by enabling higher performance and reliability that would otherwise be unattainable.

"Reinforced" vs. "Filled" Terminology

It is important to note that material vendors sometimes use the terms 'ceramic-reinforced' and 'ceramic-filled' interchangeably. Always consult the material datasheet to understand the specific composition and properties.

Fabrication Challenges

While based on PTFE, these advanced laminates can have unique processing requirements compared to more common materials like FR-4. Working with an experienced PCB fabricator who understands these materials is crucial for success.

Making the Right Choice for Your Goal

The decision between standard glass-reinforced and ceramic-filled PTFE laminates hinges on the specific demands of your application.

- If your primary focus is extreme signal integrity for high-frequency RF/microwave circuits: Ceramic-filled PTFE is the superior choice for its uniform electrical properties and phase stability.

- If your primary focus is cost-sensitive high-frequency design where minor signal variations are acceptable: Glass-reinforced PTFE offers excellent performance and is a proven, reliable option.

- If your primary focus is thermal management for high-power components: The enhanced thermal conductivity of ceramic-filled laminates makes them a clear winner.

Ultimately, selecting the right PTFE laminate depends on a clear understanding of your circuit's sensitivity to signal phase, thermal load, and mechanical stress.

Summary Table:

| Feature | Standard PTFE Laminate | Ceramic-Filled PTFE Laminate |

|---|---|---|

| Reinforcement Type | Woven Glass Fabric | Ceramic Particles |

| Dielectric Uniformity | Lower (Fiber Weave Effect) | High (Isotropic Properties) |

| Thermal Conductivity | Standard | Enhanced |

| Key Advantage | Cost-Effective | Superior Signal Integrity & Thermal Management |

| Ideal Application | Cost-Sensitive High-Frequency | High-Performance RF/Microwave |

Need a PTFE laminate solution for your high-frequency application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom laminates for the semiconductor, medical, and laboratory industries. Our expertise ensures you get the right material properties—whether you need the uniform electrical performance of ceramic-filled PTFE or the cost-effectiveness of standard reinforced PTFE.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact requirements for signal integrity, thermal management, and mechanical stability.

Contact us today to discuss your project and let our experts help you achieve optimal performance and reliability.

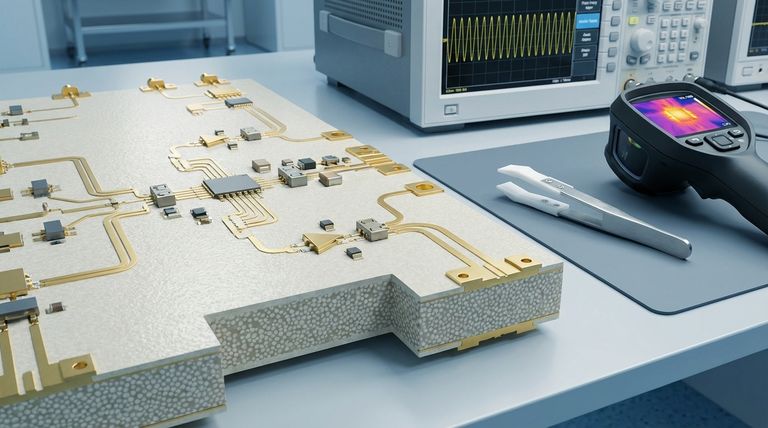

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability