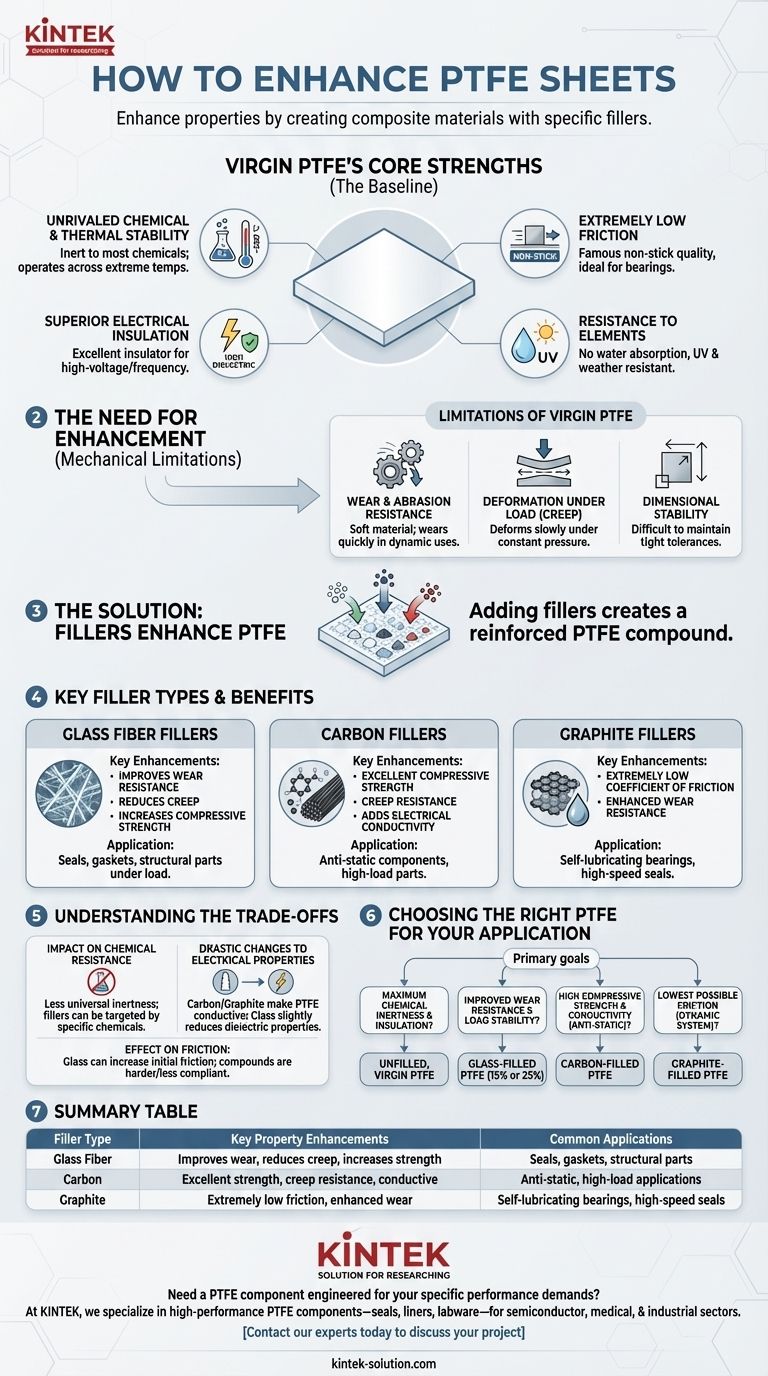

The most direct way to enhance the properties of Polytetrafluoroethylene (PTFE) sheets is by creating a composite material through the addition of fillers. While virgin PTFE is an extraordinary material, incorporating specific additives like glass fiber, carbon, or graphite targets and improves its mechanical properties, such as wear resistance and strength under load, which can be limitations in certain demanding applications.

The core challenge with virgin PTFE is not its chemical or thermal resistance, but its relative softness and tendency to deform (creep) under pressure. Enhancing PTFE is a strategic trade-off: you sacrifice some of its universal inertness to gain significant improvements in mechanical strength and wear life.

First, Understanding Virgin PTFE's Core Strengths

To appreciate the enhancements, we must first establish the exceptional baseline of virgin, or unfilled, PTFE. This material is renowned for a unique combination of high-performance characteristics.

Unrivaled Chemical and Thermal Stability

Pure PTFE is almost completely chemically inert, resisting nearly all industrial chemicals, fuels, and solvents. It also operates effectively across an extremely wide temperature range, typically from -190°C to +260°C (-310°F to +500°F), without losing its physical properties.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it the "non-stick" quality it is famous for, making it ideal for bearings, seals, and low-friction surfaces.

Superior Electrical Insulation

As an excellent electrical insulator with high dielectric strength, virgin PTFE is a go-to material for high-frequency and high-voltage applications. Its electrical properties remain stable across wide temperature and frequency ranges.

Resistance to Elements

PTFE does not absorb water (less than 0.01%), is highly resistant to UV radiation, and does not degrade or become brittle with age or exposure to weather.

The Primary Driver for Enhancement: Mechanical Limitations

Despite its strengths, virgin PTFE is a relatively soft material. For applications involving significant mechanical stress, pressure, or abrasive forces, its inherent properties can be a limiting factor.

Wear and Abrasion Resistance

In dynamic applications like seals or bearings, pure PTFE can wear down relatively quickly when subjected to friction and abrasion.

Deformation Under Load (Creep)

When a constant compressive force is applied, especially at elevated temperatures, virgin PTFE has a tendency to slowly deform or "creep" over time. This can compromise the integrity of seals and gaskets.

Dimensional Stability

The softness of the material means it can be more difficult to maintain tight dimensional tolerances, particularly under mechanical or thermal stress.

How Fillers Enhance PTFE Properties

Adding fillers creates a PTFE compound, a composite material where the filler acts as a reinforcing agent within the PTFE matrix. This is the standard industry method for overcoming PTFE's mechanical weaknesses.

Glass Fiber Fillers

Glass fiber is the most common filler. Adding it (typically in 15% or 25% concentrations) dramatically improves wear resistance and reduces creep.

It also significantly increases compressive strength and overall dimensional stability, making it a superior choice for seals, gaskets, and structural parts that operate under load.

Carbon Fillers

Adding carbon in granular or fiber form provides excellent compressive strength and creep resistance, often superior to glass.

Critically, carbon also adds electrical conductivity, transforming PTFE from an insulator into a material suitable for anti-static applications. It also enhances wear resistance and hardness.

Graphite Fillers

Graphite is a lubricant. When added to PTFE, it creates a compound with an extremely low coefficient of friction, even lower than virgin PTFE in some cases.

It is often blended with other fillers like carbon or glass to improve wear properties while maintaining low friction in dynamic, high-speed applications.

Understanding the Trade-offs

Enhancing PTFE is not a "free upgrade." The choice of filler introduces specific trade-offs that are critical to understand for any engineering application.

Impact on Chemical Resistance

While filled PTFE is still highly resistant, it does not possess the near-universal chemical inertness of virgin PTFE. The filler itself can be attacked by certain chemicals. For instance, glass fibers can be targeted by strong alkalis or hydrofluoric acid.

Drastic Changes to Electrical Properties

The most significant trade-off involves electrical insulation. Adding carbon or graphite makes the material conductive, completely negating its use as an electrical insulator. Glass-filled PTFE retains good, but slightly reduced, dielectric properties compared to the virgin grade.

Effect on Friction and Compliance

While graphite lowers friction, other fillers like glass can slightly increase the initial coefficient of friction compared to pure PTFE. The resulting compound is also harder and less compliant, which can be a factor in sealing applications requiring flexibility.

Choosing the Right PTFE for Your Application

Selecting the correct PTFE formulation requires a clear understanding of your primary engineering goal.

- If your primary focus is maximum chemical inertness and electrical insulation: Unfilled, virgin PTFE is the only choice. Its purity is its greatest strength in these domains.

- If your primary focus is improved wear resistance and stability under load: A glass-filled PTFE compound (15% or 25%) is the standard, cost-effective solution for most mechanical applications.

- If your primary focus is high compressive strength and electrical conductivity (for anti-static): A carbon-filled PTFE compound provides excellent mechanical strength and prevents the buildup of static electricity.

- If your primary focus is the lowest possible friction in a high-wear, dynamic system: A graphite-filled PTFE compound is specifically engineered for self-lubricating bearing and seal applications.

By understanding these modifications, you can select a PTFE material precisely engineered to meet your specific performance demands.

Summary Table:

| Filler Type | Key Property Enhancements | Common Applications |

|---|---|---|

| Glass Fiber | Improves wear resistance, reduces creep, increases compressive strength | Seals, gaskets, structural parts |

| Carbon | Excellent compressive strength, creep resistance, adds electrical conductivity | Anti-static components, high-load applications |

| Graphite | Extremely low coefficient of friction, enhanced wear resistance | Self-lubricating bearings, high-speed seals |

Need a PTFE component engineered for your specific performance demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the chemical purity of virgin PTFE or the enhanced mechanical properties of a filled compound, our precision production and custom fabrication services ensure you get the exact material solution for your application, from prototypes to high-volume orders.

Contact our experts today to discuss your project and receive a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts