At its core, a Teflon PTFE sheet serves as an indispensable, reusable barrier for crafting with glue or resin. Its primary function is to create a completely non-stick work surface, which prevents adhesives from permanently bonding to your table or tools. This ensures any spills or excess material can be easily removed once cured, leading to a clean, efficient, and mess-free creative process.

The true value of a PTFE sheet in a crafting environment is its unique combination of non-stick performance, high heat resistance, and reusability. This trifecta transforms it from a simple protective layer into a long-term tool that saves you time, materials, and money.

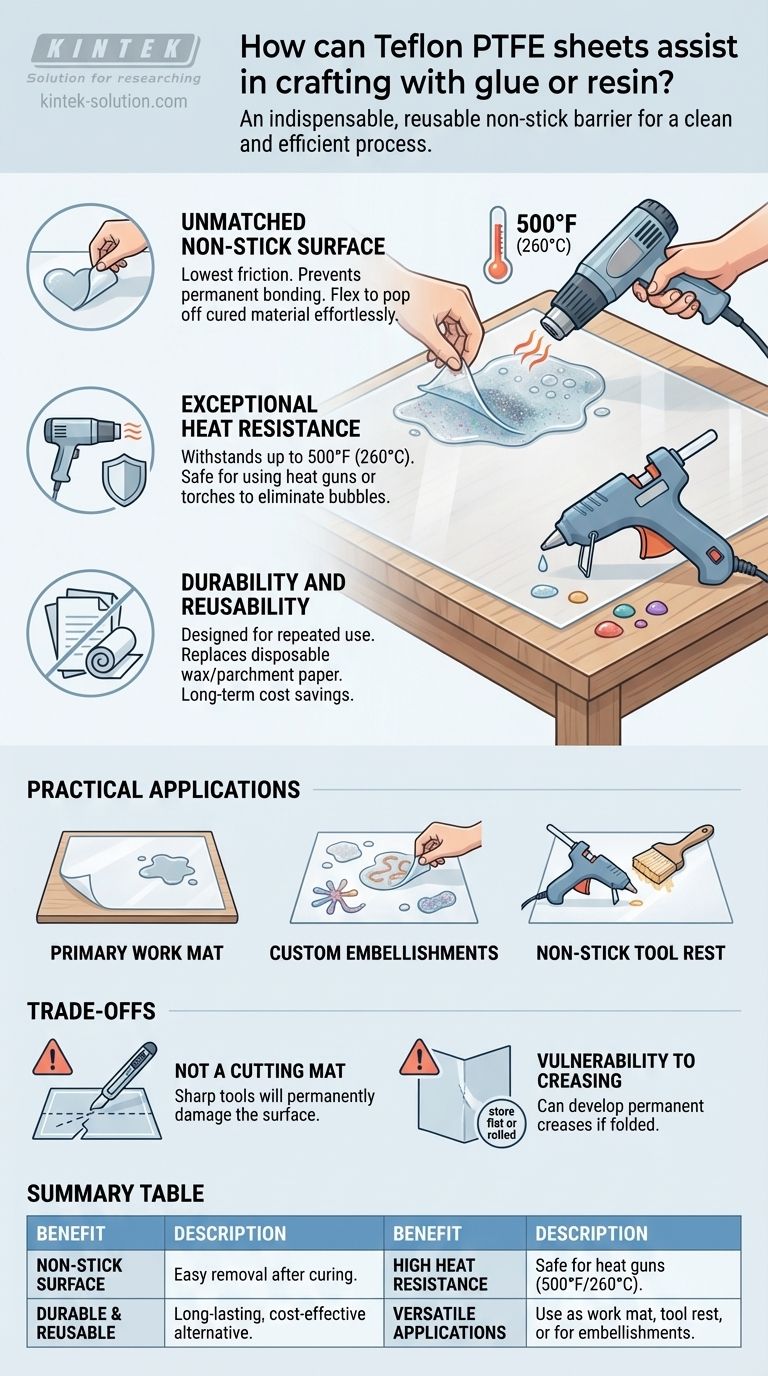

The Core Principles: Why PTFE Excels

To understand how a PTFE sheet can elevate your crafting, it's important to grasp the material properties that make it so effective.

Unmatched Non-Stick Surface

PTFE (Polytetrafluoroethylene) has one of the lowest coefficients of friction of any solid. In practical terms, this means almost nothing sticks to it.

Once glue or resin has fully cured on the sheet, it will not be bonded to the surface. You can simply flex the sheet to pop the material off or peel it away with minimal effort, leaving a clean surface behind.

Exceptional Heat Resistance

These sheets are engineered to withstand high temperatures, often up to 500°F (260°C).

This is a critical feature for resin artists who frequently use a heat gun or torch to eliminate bubbles from their projects. A PTFE sheet allows you to apply heat directly without fear of melting or damaging the sheet or the work surface beneath it.

Durability and Reusability

Unlike disposable options like wax or parchment paper, a PTFE sheet is designed for repeated use.

A quick wipe is usually all that's needed to clean it. This durability not only reduces waste but also provides significant cost savings over time by eliminating the need to constantly repurchase disposable surface protectors.

Practical Applications in Your Workspace

Beyond simple surface protection, a PTFE sheet can be integrated into your workflow in several strategic ways.

As a Primary Work Mat

The most common application is to lay a sheet down to define your entire workspace. This contains all drips and spills from resin pours or glue applications, protecting your desk or table from accidental damage.

For Creating Custom Embellishments

You can apply hot glue, puff paint, or even thin layers of resin directly onto the sheet in specific designs. Once cured, these "skins" or embellishments can be peeled off and used in other projects.

As a Non-Stick Tool Rest

A PTFE sheet is the perfect place to set down a hot glue gun, a sticky stir stick, or a resin-covered brush. The adhesive will not permanently bond to the sheet, making tool cleanup significantly easier.

Understanding the Trade-offs

While highly effective, it's important to recognize the limitations of a PTFE sheet to use it correctly.

Not a Cutting Mat

A key distinction is that a PTFE sheet is not a self-healing cutting mat. Using a craft knife or other sharp tool directly on the surface will slice or scratch it permanently, compromising its integrity.

Vulnerability to Creasing

While flexible, the sheets can develop permanent creases if folded sharply. It is always best to store them rolled or flat to maintain a smooth, even work surface.

Making the Right Choice for Your Craft

To apply this effectively, consider your primary crafting activity.

- If your primary focus is large resin pours: Use a large sheet to cover your entire work area, leveraging its heat resistance and spill-proof nature.

- If your primary focus is precision glue work: Use a smaller sheet as a dedicated palette for dabbing glue or as a safe resting spot for your hot glue gun.

- If your primary focus is long-term value and sustainability: Invest in a quality PTFE sheet to replace single-use papers, saving money and reducing waste with every project.

Ultimately, integrating a PTFE sheet into your workflow is an investment in a cleaner, more efficient, and less wasteful creative process.

Summary Table:

| Benefit | Description |

|---|---|

| Non-Stick Surface | Prevents glue/resin from bonding, allowing for easy removal after curing. |

| High Heat Resistance | Withstands heat guns or torches (up to 500°F/260°C) for bubble removal. |

| Durable & Reusable | A long-lasting alternative to disposable papers, saving money over time. |

| Versatile Applications | Use as a work mat, for creating custom embellishments, or as a tool rest. |

Ready to transform your crafting process with a high-performance PTFE sheet?

At KINTEK, we specialize in manufacturing precision PTFE components, including durable, non-stick sheets perfect for demanding applications in laboratories, industrial settings, and specialized crafts. Whether you need a standard size or a custom-fabricated solution, from a single prototype to a high-volume order, we are committed to delivering the quality and performance your projects demand.

Contact us today to discuss your needs and discover how our PTFE solutions can bring efficiency and cleanliness to your workspace!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry