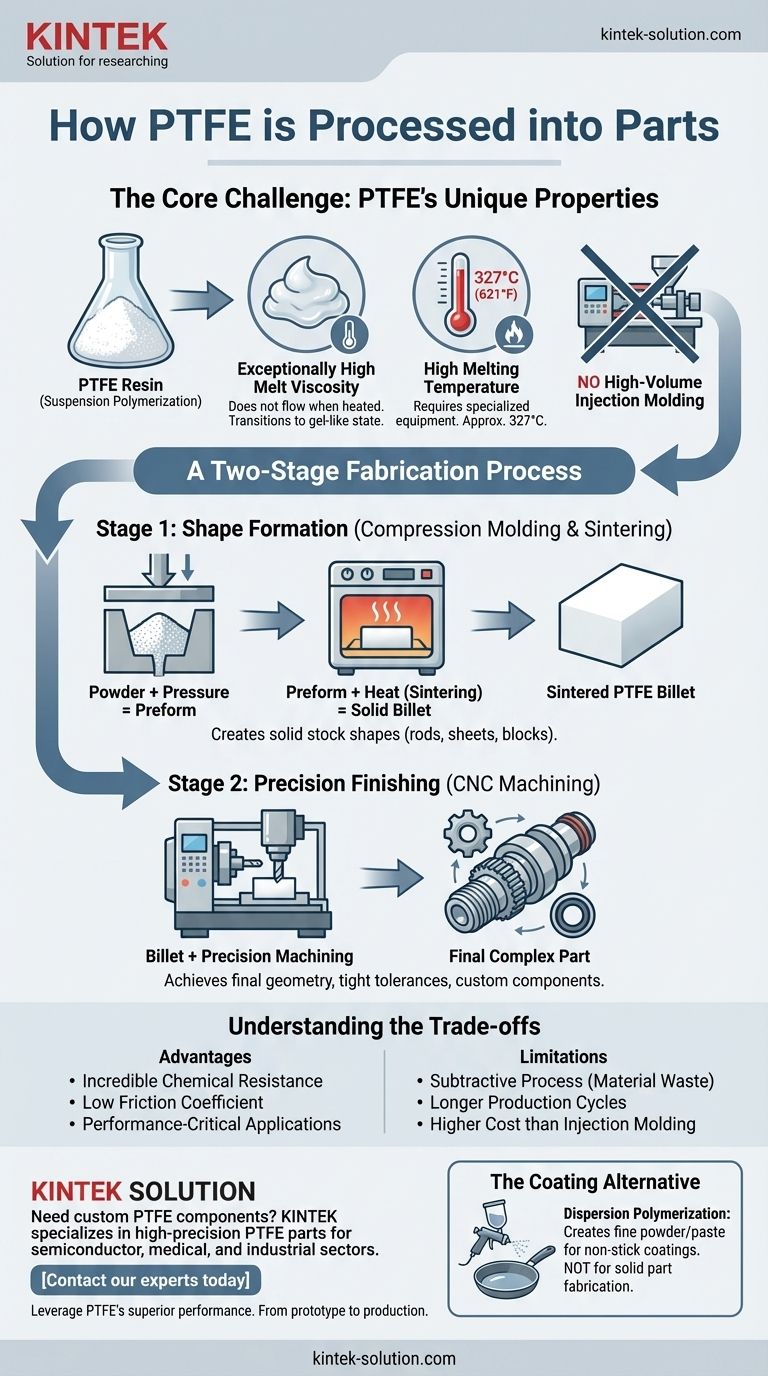

To process Polytetrafluoroethylene (PTFE) into finished parts, manufacturers primarily use a two-stage method involving compression molding and subsequent CNC machining. Unlike common thermoplastics, PTFE has an extremely high melt viscosity, meaning it does not flow when heated and therefore cannot be processed using conventional methods like injection molding.

The core challenge with PTFE is that it doesn't melt into a liquid state; it becomes a non-flowing gel. This fundamental property makes traditional high-volume plastic processing impossible, necessitating a specialized approach of first molding a basic shape and then machining it to final, precise specifications.

The Core Challenge: Why PTFE is Different

PTFE's unique molecular structure gives it incredible chemical resistance and a low friction coefficient, but it also presents significant processing challenges. Understanding these challenges is key to understanding its fabrication methods.

Exceptionally High Melt Viscosity

When heated past its melting point, PTFE does not turn into a flowable liquid like other plastics. Instead, it transitions into a gel-like state that is too thick to be forced into a complex mold. This is the single biggest reason it cannot be injection molded.

High Melting Temperature

PTFE has a very high melting temperature (around 327°C or 621°F), which further complicates processing and requires specialized equipment capable of handling such heat consistently and safely.

A Two-Stage Fabrication Process

To overcome its inherent limitations, PTFE parts are typically created through a process that separates the formation of the basic material shape from the creation of the final detailed geometry.

Step 1: Compression Molding and Sintering

The process begins with PTFE resin, usually in a granular or pellet form. This raw material is produced through a method called suspension polymerization.

The powder is poured into a mold (typically a simple shape like a cylinder or block) and compressed under high pressure to form a solid "preform" or "billet." This preform is then heated in an oven in a process called sintering, which fuses the PTFE particles together into a solid, dense block of material.

Step 2: Precision Machining

Once the sintered billet has cooled, it serves as the stock material for fabrication. This solid block is then taken to a CNC (Computer Numerical Control) machine.

Using precision cutting, turning, and milling, the billet is shaped into the final part with tight tolerances. This subtractive process allows for the creation of everything from simple washers to highly complex components like custom seals, insulators, and valve seats.

Understanding the Trade-offs

The specialized processing required for PTFE creates a distinct set of advantages and limitations that engineers must consider.

No High-Volume Injection Molding

The inability to injection mold is the primary trade-off. This prevents the rapid, low-cost production of thousands of identical, complex parts that is possible with plastics like nylon or polycarbonate.

Impact on Cost and Design

Machining is a subtractive process, which means material is wasted to create the final shape. This can be less cost-effective than the near-net-shape process of injection molding. Production cycles are also longer, making PTFE a choice for performance-critical applications rather than mass-market consumer goods.

The Coating Alternative

It's important to distinguish part fabrication from coatings. A different production method, dispersion polymerization, creates a fine PTFE powder or paste. This material is used to create the non-stick coatings found on cookware and industrial surfaces, which is a separate application from creating solid, machined parts.

Making the Right Choice for Your Goal

The correct approach depends entirely on what you need PTFE to do.

- If your primary focus is creating standard stock shapes (rods, sheets): The compression molding and sintering process is used to produce these bulk materials for further machining.

- If your primary focus is producing custom, high-precision components: The necessary path is to CNC machine parts from a pre-molded and sintered PTFE billet.

- If your primary focus is applying a non-stick surface: You are not fabricating a part, but rather using PTFE produced as a dispersion for a coating application.

Understanding this essential molding-then-machining workflow is the key to successfully leveraging PTFE's unparalleled performance in your most demanding applications.

Summary Table:

| PTFE Processing Stage | Key Process | Primary Outcome |

|---|---|---|

| Stage 1: Shape Formation | Compression Molding & Sintering | Creates a solid PTFE billet or preform |

| Stage 2: Precision Finishing | CNC Machining | Achieves final part geometry and tight tolerations |

Need custom PTFE components that meet exact specifications?

KINTEK specializes in manufacturing high-precision PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our process ensures material integrity and performance, from prototype development to high-volume production.

Contact our experts today to discuss your project requirements and leverage PTFE's superior chemical resistance and low friction in your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs