To put it simply, Polytetrafluoroethylene (PTFE) is not fabricated like common plastics. Instead of melting, it is typically compressed into a solid form and then heated in a process called sintering. It is commercially available in forms ranging from raw powders and dispersions for coatings to solid stock shapes like rods, sheets, and fabrics for machining.

PTFE’s exceptional chemical inertness and non-stick properties are a direct result of its unique molecular structure, which also dictates its specialized fabrication methods. Understanding that it must be sintered rather than melted is the key to successfully designing and manufacturing parts with this high-performance polymer.

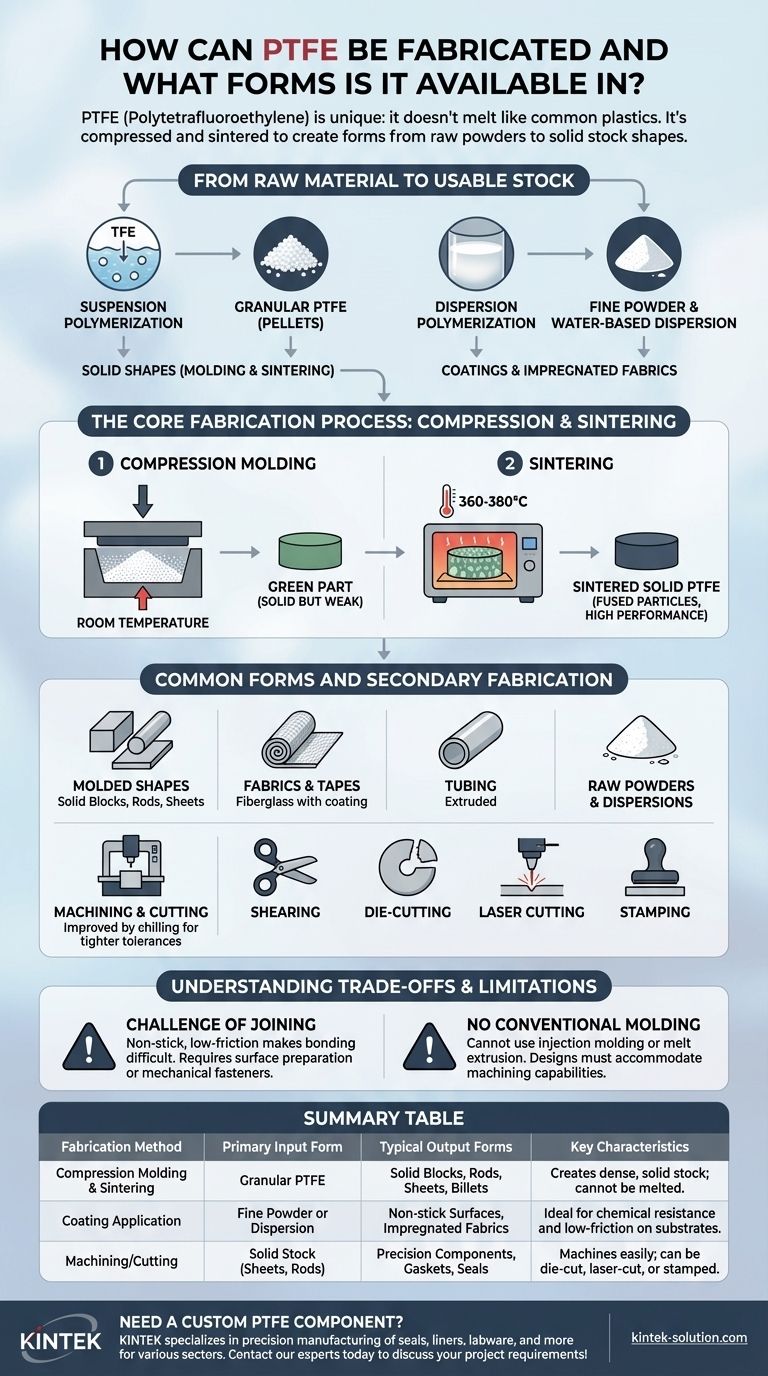

From Raw Material to Usable Stock

To understand how to work with PTFE, you must first understand how its fundamental forms are created. The process begins with one of two polymerization methods that yield distinct types of raw material.

Suspension Polymerization for Solid Shapes

This method polymerizes Tetrafluoroethylene (TFE) in water, resulting in granular PTFE.

These grains, which can be processed into pellets, are the primary raw material used for creating solid stock shapes through molding and sintering.

Dispersion Polymerization for Coatings

This alternative method produces a milky paste that can be further processed into a fine powder or used as a water-based dispersion.

These forms are ideal for creating the non-stick coatings found on cookware or for impregnating materials like fiberglass to create PTFE fabrics.

The Core Fabrication Process: Compression and Sintering

Unlike thermoplastics that can be melted and injected into a mold, granular PTFE has an extremely high melt viscosity, making it impractical to process in that way.

Step 1: Compression Molding

The process begins by compressing the granular PTFE powder or pellets into a preform shape at room temperature. This "green" part is solid but lacks mechanical strength.

Step 2: Sintering

The preform is then heated in a carefully controlled oven to a temperature below its melting point (around 360-380°C). During this sintering phase, the individual PTFE particles fuse together, creating a solid, dense material with its renowned properties.

This compression and sintering cycle is used to create the common stock shapes that are then used for final part fabrication.

Common Forms and Secondary Fabrication

Once PTFE is sintered into a bulk form, it can be sourced in several standard shapes and further processed into finished components.

Available Stock Forms

PTFE is most commonly available as:

- Molded Shapes: Solid blocks, rods, sheets, and billets.

- Fabrics and Tapes: Often made by coating fiberglass with a PTFE dispersion.

- Tubing: Extruded for fluid transfer applications.

- Raw Powders & Dispersions: For custom coating applications.

Machining and Cutting

Once in a solid stock form, PTFE is readily fabricated into precise components. It machines very easily, and this process can be improved by chilling the material to achieve tighter tolerances and a better surface finish.

Common fabrication services for sheet and film include shearing, die-cutting, laser cutting, and stamping to produce items like gaskets and seals.

Understanding the Trade-offs and Limitations

While versatile, PTFE's unique nature presents critical limitations that must be respected in any design.

The Challenge of Joining

PTFE's defining non-stick, low-friction surface makes it extremely difficult to bond or weld. Standard adhesives will not work, and joining PTFE parts requires specialized surface preparation like chemical etching or the use of mechanical fasteners.

No Conventional Molding

The inability to use traditional injection molding or melt extrusion means that highly complex part geometries can be more difficult or expensive to produce compared to other plastics. Designs must accommodate the capabilities of machining from solid stock.

Making the Right Choice for Your Application

Selecting the correct form and fabrication method is essential for a successful outcome.

- If your primary focus is creating custom solid components: Your best path is to start with molded PTFE stock (rods, sheets) and use standard machining techniques.

- If your primary focus is a non-stick or chemically resistant surface: You should specify a PTFE coating, which is applied using fine powder or dispersion forms.

- If your primary focus is flexible seals, gaskets, or liners: Sourced PTFE sheets, fabrics, or tapes that can be die-cut or stamped are the most effective solution.

By aligning your design requirements with PTFE's specific fabrication pathways, you can fully capitalize on its exceptional material properties.

Summary Table:

| Fabrication Method | Primary Input Form | Typical Output Forms | Key Characteristics |

|---|---|---|---|

| Compression Molding & Sintering | Granular PTFE | Solid Blocks, Rods, Sheets, Billets | Creates dense, solid stock for machining; cannot be melted like standard plastics. |

| Coating Application | Fine Powder or Dispersion | Non-stick Surfaces, Impregnated Fabrics | Ideal for chemical resistance and low-friction surfaces on substrates. |

| Machining/Cutting | Solid Stock (Sheets, Rods) | Precision Components, Gaskets, Seals | Machines easily; can be die-cut, laser-cut, or stamped to final shape. |

Need a custom PTFE component? KINTEK specializes in precision manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in custom fabrication ensures you get the right part for your application. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials