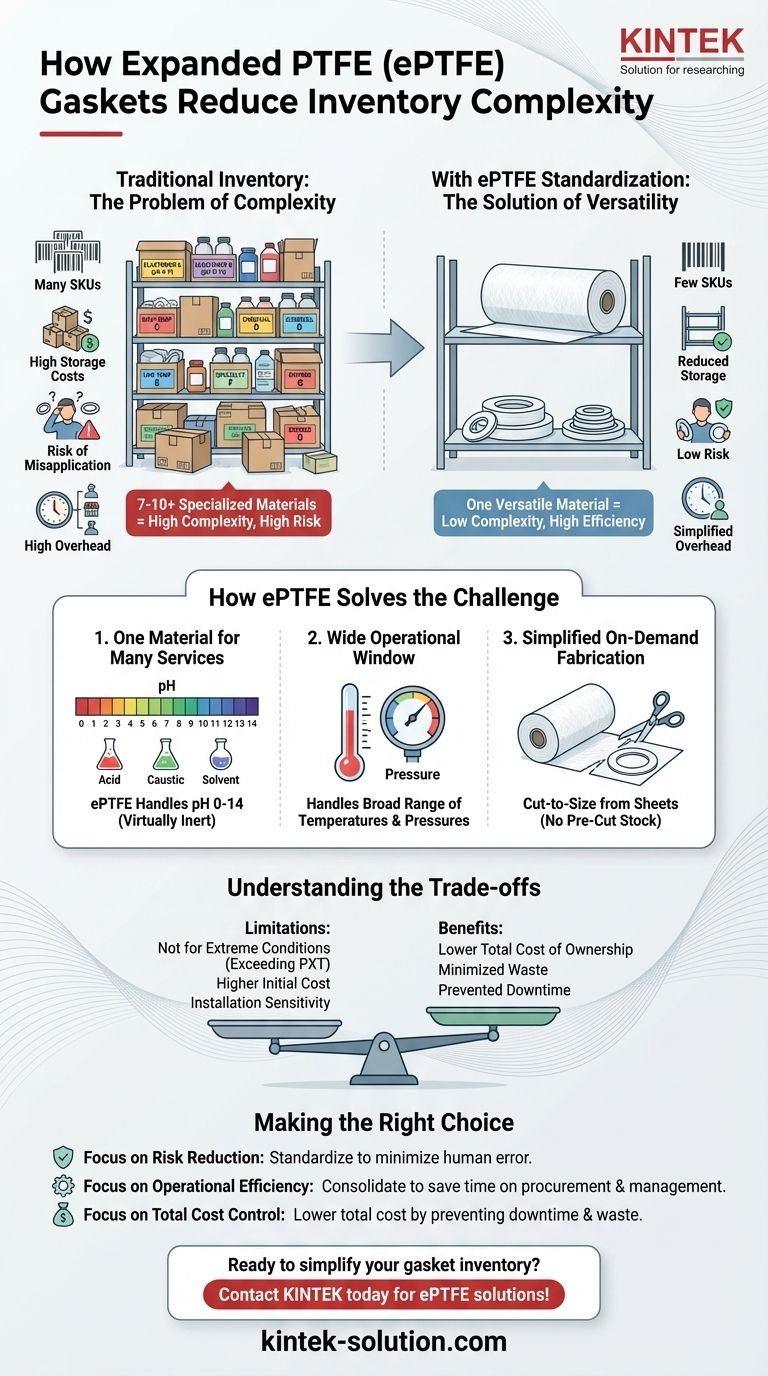

Expanded PTFE (ePTFE) gaskets dramatically simplify inventory by functioning as a high-performance, multi-purpose sealing material. Because of their exceptional chemical resistance and temperature tolerance, a single type of ePTFE can effectively replace 7-10 different specialized gasket materials. This consolidation directly reduces the number of unique items you need to stock, track, and manage.

The fundamental problem with a complex gasket inventory isn't just the physical storage space—it's the significant operational risk of incorrect material selection. By standardizing on ePTFE, you replace an error-prone system with a single, versatile solution, minimizing both logistical overhead and the potential for catastrophic sealing failures.

The Problem with Specialized Gasket Inventories

Managing a large and diverse stock of gaskets introduces significant costs and risks that extend far beyond the warehouse shelves. This complexity creates hidden inefficiencies that can impact your entire operation.

The High Cost of Complexity

Every unique gasket type you stock is a separate stock-keeping unit (SKU). Each SKU requires capital investment, storage space, and administrative time for procurement and tracking. Many specialized gaskets also have a limited shelf life, leading to waste if they are not used in time.

The Hidden Risk of Misapplication

When a maintenance team has access to numerous visually similar but functionally different gasket types, the risk of human error increases dramatically. Selecting the wrong material for a specific chemical service or temperature can lead to immediate seal failure, resulting in production losses, costly downtime, and severe safety hazards.

Procurement and Logistical Overhead

Sourcing multiple gasket types means managing relationships with several vendors, tracking different lead times, and constantly monitoring minimum stock levels for each item. This administrative burden consumes valuable time that could be dedicated to more critical maintenance and reliability tasks.

How ePTFE Solves the Inventory Challenge

Expanded PTFE addresses these challenges by replacing specialization with versatility. Its unique material properties allow it to perform reliably in a wide array of applications where multiple different materials were previously required.

One Material for Many Services

ePTFE is created by expanding virgin PTFE, which gives it a strong, multi-directional fibrous structure. This material is virtually inert to all chemicals on the pH scale (0-14), with the exception of molten alkali metals and elemental fluorine. This allows it to be the default choice for acids, caustics, solvents, and other aggressive media, eliminating the need for numerous specialty elastomer gaskets.

Wide Operational Window

The inherent durability of PTFE means it can handle a broad range of temperatures and pressures. A single sheet of ePTFE can often replace separate gaskets previously stocked for low-temperature, moderate-temperature, and chemically demanding services, further consolidating your inventory needs.

Simplified On-Demand Fabrication

Unlike pre-cut gaskets that must be stocked in every required size, ePTFE is typically supplied in large sheets. This allows maintenance teams to cut the exact gasket size they need, when they need it. This "cut-your-own" approach eliminates the need to stock dozens of different sizes for various flanges, representing a massive reduction in inventory complexity.

Understanding the Trade-offs

While ePTFE is a powerful solution for inventory simplification, it is not a universal fix for every sealing application. Objectivity requires acknowledging its limitations.

Not for Extreme Conditions

For extremely high-pressure or high-temperature applications, metallic or semi-metallic gaskets remain the superior choice. ePTFE has limits and should not be used in services that exceed the manufacturer's pressure-temperature (PXT) ratings.

Higher Initial Material Cost

On a per-sheet basis, ePTFE can be more expensive than some basic elastomer gaskets it replaces. However, this higher upfront cost is typically offset by a lower total cost of ownership when you factor in reduced inventory holding costs, minimized waste, and the prevention of costly downtime.

Installation Sensitivity

The performance of ePTFE gaskets is highly dependent on proper installation practices, including clean flange surfaces and correct bolt torque. It is less forgiving of poor installation techniques than some softer, more pliable gasket materials.

Making the Right Choice for Your Facility

Adopting ePTFE is a strategic move to enhance operational reliability. To decide if it's the right path, consider your primary operational drivers.

- If your primary focus is risk reduction: Standardizing on ePTFE is one of the most effective ways to minimize the chance of human error in gasket selection, directly preventing leaks and associated safety incidents.

- If your primary focus is operational efficiency: Consolidating your gasket inventory to ePTFE sheets drastically reduces the time your team spends on procurement, stock management, and finding the right part for the job.

- If your primary focus is total cost control: ePTFE lowers the total cost of ownership by preventing expensive downtime from incorrect gasket applications and eliminating waste from expired, specialized stock.

Ultimately, standardizing on ePTFE allows you to trade unnecessary material complexity for enhanced operational certainty.

Summary Table:

| Aspect | Traditional Inventory | With ePTFE Standardization |

|---|---|---|

| Number of SKUs | 7-10+ specialized materials | 1 versatile material |

| Chemical Resistance | Multiple materials for different pH levels | Single material handles pH 0-14 |

| Risk of Misapplication | High (human error) | Low (single, versatile choice) |

| Storage & Management | Complex, high overhead | Simplified, reduced space |

| On-Demand Fabrication | Requires pre-cut sizes | Cut-to-size from sheets |

Ready to simplify your gasket inventory and reduce operational risk?

At KINTEK, we specialize in manufacturing high-precision PTFE and ePTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact sealing solution your facility needs.

Let us help you standardize on ePTFE for safer, more efficient operations. Contact KINTEB today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F