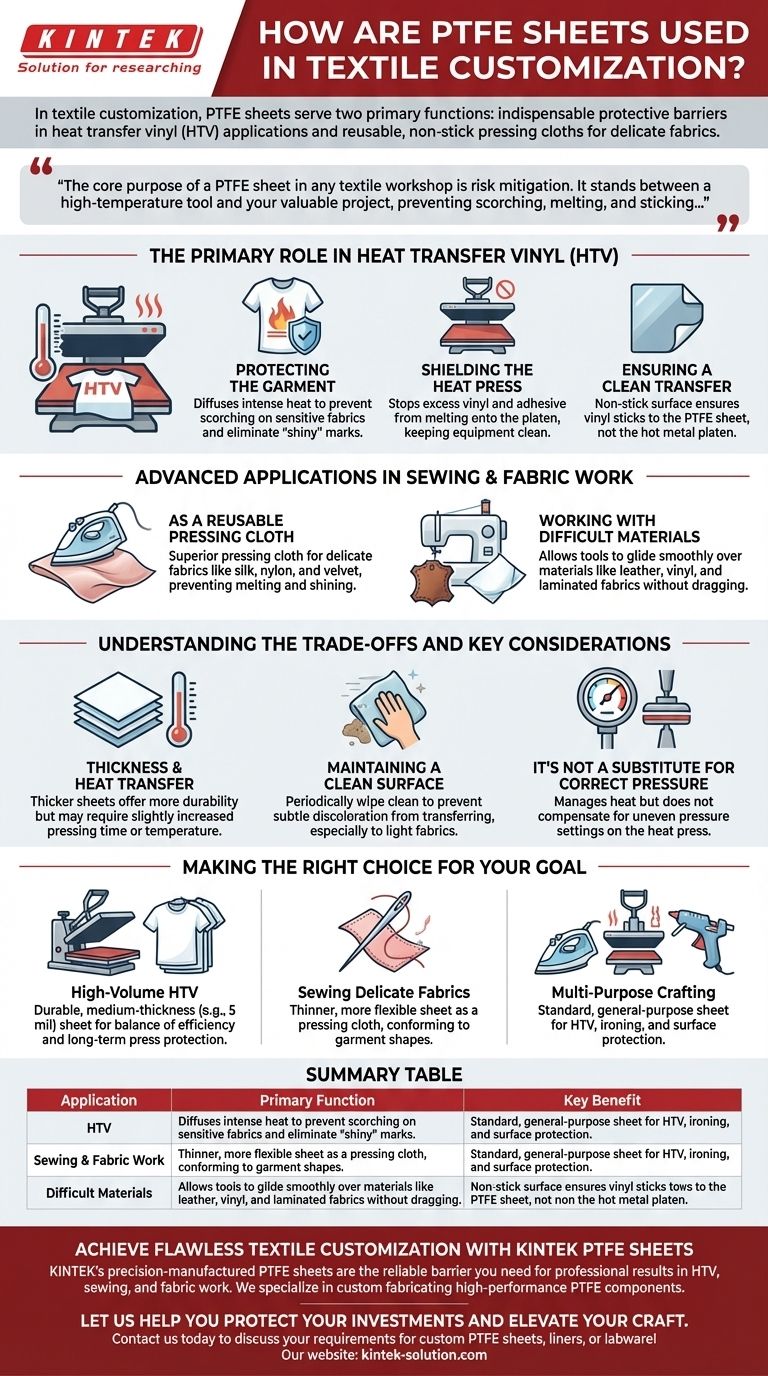

In textile customization, PTFE sheets serve two primary functions. They are indispensable protective barriers in heat transfer vinyl (HTV) applications and act as reusable, non-stick pressing cloths for delicate or difficult-to-work-with fabrics. Their value comes from a unique combination of extreme heat resistance and an exceptionally slick surface.

The core purpose of a PTFE sheet in any textile workshop is risk mitigation. It stands between a high-temperature tool and your valuable project, preventing scorching, melting, and sticking to ensure a clean, professional outcome.

The Primary Role in Heat Transfer Vinyl (HTV)

The most common use for PTFE sheets is as a protective layer during the heat press process. It is placed directly over the HTV design and garment before closing the press.

Protecting the Garment

A PTFE sheet diffuses the direct, intense heat from the press platen. This prevents scorching on sensitive fabrics like polyester and eliminates the "shiny" marks that can appear on darker cottons from direct heat and pressure.

Shielding the Heat Press

It creates a critical barrier that stops any excess vinyl, adhesive, or ink from melting and adhering to the upper platen of your heat press. This keeps your equipment clean and prevents ghost images from being accidentally transferred to subsequent projects.

Ensuring a Clean Transfer

The non-stick surface ensures that if any part of the vinyl carrier sheet or design were to stick, it would stick to the easily removed PTFE sheet rather than the hot metal platen.

Advanced Applications in Sewing and Fabric Work

Beyond HTV, the properties of PTFE make it a versatile tool for general sewing and fabric manipulation.

As a Reusable Pressing Cloth

When ironing delicate fabrics like silk, nylon, or velvet, a PTFE sheet acts as a superior pressing cloth. It protects the material from direct contact with the iron's soleplate, preventing melting, shining, or damage to the fabric's texture.

Working with Difficult Materials

Materials like leather, vinyl, and laminated fabrics can be challenging to work with as they may stick to a sewing machine's presser foot or an iron. Placing a PTFE sheet over the material allows tools to glide smoothly across the surface without dragging or marring.

Understanding the Trade-offs and Key Considerations

While highly effective, understanding the nuances of these sheets allows for better results.

Thickness and Heat Transfer

PTFE sheets come in various thicknesses. A thicker sheet offers more durability and protection but may slightly insulate the garment, potentially requiring a minor increase in pressing time or temperature to achieve proper adhesion.

Maintaining a Clean Surface

Although PTFE is non-stick, a well-used sheet can accumulate a very fine residue over time. It's crucial to wipe the sheet clean periodically to prevent any subtle discoloration from transferring to your garments, especially when working with white or light-colored fabrics.

It's Not a Substitute for Correct Pressure

A PTFE sheet excels at managing heat, but it cannot fix issues related to incorrect pressure settings on your heat press. It provides a smooth surface but will not compensate for a press that is applying uneven force across the platen.

Making the Right Choice for Your Goal

Select your sheet based on its intended application to maximize its effectiveness.

- If your primary focus is high-volume HTV apparel: A durable, medium-thickness (e.g., 5 mil) sheet provides the best balance of heat transfer efficiency and long-term protection for your press.

- If your primary focus is sewing delicate fabrics: A thinner, more flexible sheet works perfectly as a pressing cloth, easily conforming to the shape of the garment under an iron.

- If your primary focus is multi-purpose crafting: A standard, general-purpose PTFE sheet will capably handle HTV projects, ironing, and protecting work surfaces from glues or paints.

By leveraging its simple yet powerful properties, the PTFE sheet becomes a fundamental tool for achieving consistent, damage-free results in your textile work.

Summary Table:

| Application | Primary Function | Key Benefit |

|---|---|---|

| Heat Transfer Vinyl (HTV) | Protective barrier during pressing | Prevents scorching, eliminates shiny marks, and protects the heat press |

| Sewing & Fabric Work | Reusable pressing cloth | Protects delicate fabrics (silk, velvet) from direct iron heat and damage |

| Difficult Materials (leather, vinyl) | Non-stick surface for tools | Allows sewing machine feet and irons to glide smoothly without sticking |

Achieve Flawless Textile Customization with KINTEK PTFE Sheets

Tired of ruined projects from scorching, sticking, or press contamination? KINTEK's precision-manufactured PTFE sheets are the reliable barrier you need for professional results in HTV, sewing, and fabric work.

We specialize in custom fabricating high-performance PTFE components for demanding industries, including textile manufacturing and customization. Whether you need durable sheets for high-volume heat pressing or flexible versions for delicate ironing, we provide solutions tailored to your specific process.

Let us help you protect your investments and elevate your craft.

Contact us today to discuss your requirements for custom PTFE sheets, liners, or labware!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts