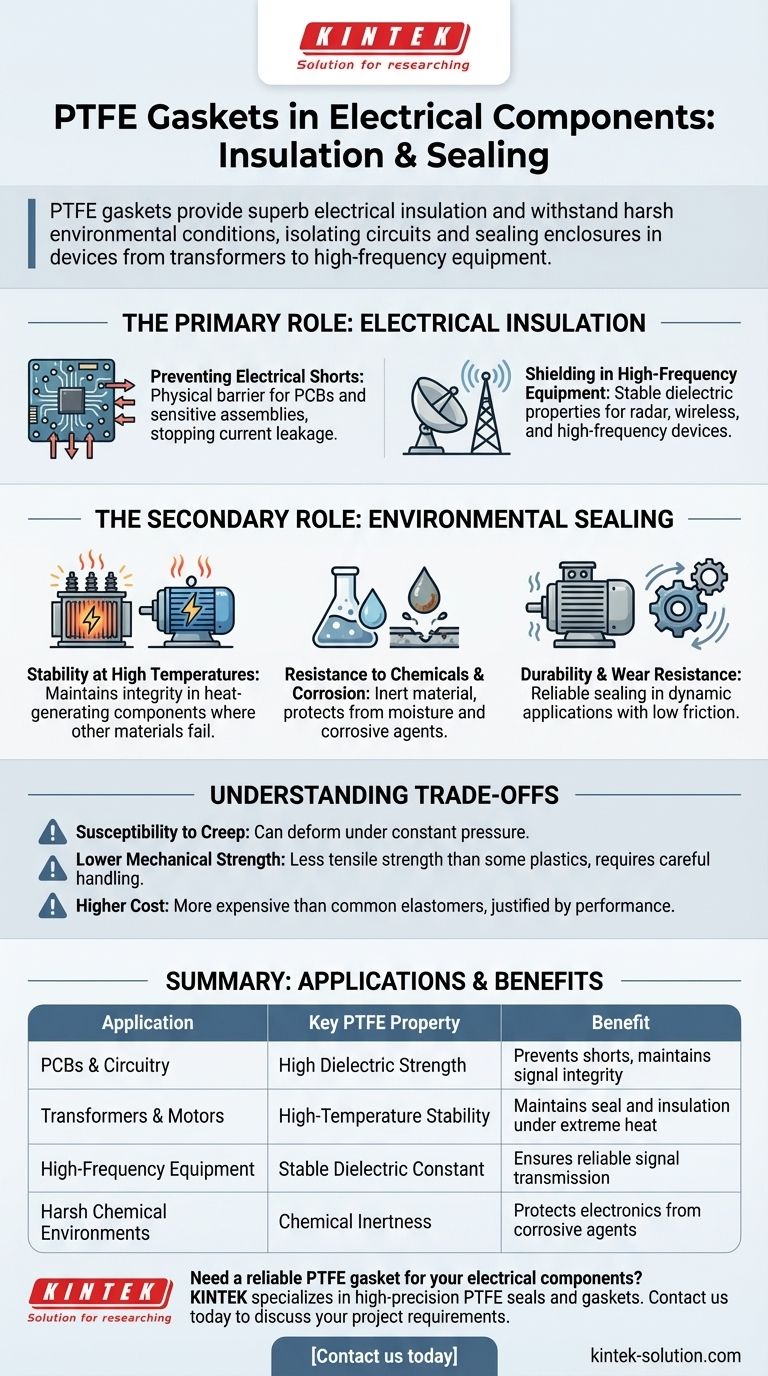

In short, PTFE gaskets are essential in electrical components for their dual ability to provide superb electrical insulation while simultaneously withstanding harsh environmental conditions. They are used to isolate circuits, prevent electrical shorts, and seal enclosures in devices ranging from transformers and electric motors to high-frequency communication equipment and printed circuit boards.

The core value of PTFE in electrical applications is its unique combination of properties: it is an exceptional dielectric insulator that also resists extreme heat, corrosive chemicals, and mechanical wear, making it a uniquely reliable material for protecting sensitive electronics.

The Primary Role: Electrical Insulation

The most critical function of PTFE in an electrical context is its inability to conduct electricity. This property, known as high dielectric strength, makes it an ideal insulator.

Preventing Electrical Shorts

PTFE gaskets are used to separate conductive components, such as on printed circuit boards (PCBs) and within sensitive electronic assemblies.

This physical barrier prevents current from leaking or short-circuiting, which could otherwise lead to component failure or damage.

Shielding in High-Frequency Equipment

The material's stable dielectric properties make it invaluable for high-frequency applications.

PTFE is used to insulate components in radar systems, wireless communication equipment, and other high-frequency devices where signal integrity is paramount.

The Secondary Role: Environmental Sealing

Beyond its electrical properties, PTFE provides a robust seal that protects sensitive components from their operating environment. This physical protection is just as critical as its insulating capability.

Stability at High Temperatures

Electrical components like transformers and electric motors generate significant heat during operation.

PTFE maintains its structural integrity and sealing performance at high temperatures where other materials, like polyethylene, would fail. This makes it ideal for gaskets within these demanding applications.

Resistance to Chemicals and Corrosion

In many industrial settings, electrical components are exposed to moisture, chemicals, or other corrosive agents.

PTFE is virtually inert, meaning it will not degrade when exposed to these substances. This ensures the gasket maintains its seal and protects the internal electronics over a long service life.

Durability and Wear Resistance

PTFE gaskets provide reliable sealing in dynamic applications with vibration or moving parts, such as within electric motors.

Its low-friction surface and resistance to wear ensure the seal remains intact, preventing contamination and maintaining operational integrity.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Its limitations are important to consider for proper application.

Susceptibility to Creep

Standard PTFE can be prone to "creep" or cold flow, meaning it can slowly deform over time when subjected to constant pressure. This can be a concern in high-pressure sealing applications that require consistent torque.

Lower Mechanical Strength

Compared to many engineering plastics, PTFE has lower tensile strength and abrasion resistance. It can be susceptible to damage during installation if not handled with care.

Higher Cost

PTFE is generally a more expensive material than common elastomers like rubber or silicone. Its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on specific operational demands.

- If your primary focus is electrical insulation, especially at high frequencies: PTFE is an industry-standard choice for components in RF, radar, and sensitive circuit boards.

- If your primary focus is sealing a component that generates high heat: PTFE's thermal stability makes it a superior option for gaskets in transformers, power supplies, and motors.

- If your primary focus is protecting electronics from harsh chemical environments: PTFE's chemical inertness provides a reliable, long-lasting seal where other materials would quickly degrade.

Ultimately, using a PTFE gasket is a strategic decision to ensure the electrical integrity, safety, and long-term reliability of a component in a demanding environment.

Summary Table:

| Application | Key PTFE Property | Benefit |

|---|---|---|

| PCBs & Circuitry | High Dielectric Strength | Prevents electrical shorts, maintains signal integrity |

| Transformers & Motors | High-Temperature Stability | Maintains seal and insulation under extreme heat |

| High-Frequency Equipment (RF, Radar) | Stable Dielectric Constant | Ensures reliable signal transmission |

| Harsh Chemical Environments | Chemical Inertness | Protects electronics from corrosive agents |

| Dynamic/Vibrating Applications | Wear Resistance & Low Friction | Provides durable, long-lasting sealing |

Need a reliable PTFE gasket for your electrical components?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for insulation, thermal stability, and chemical resistance.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance the performance and longevity of your electrical assemblies.

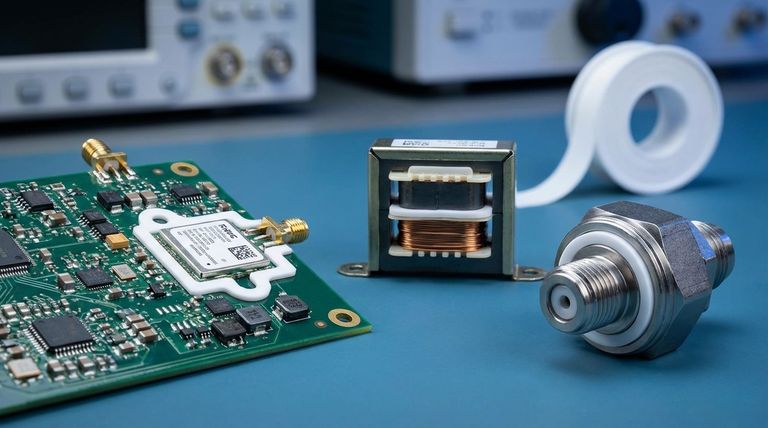

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments