In short, Polytetrafluoroethylene (PTFE) gaskets are used extensively throughout the automotive industry because of their exceptional resistance to both high temperatures and corrosive fluids. You will find them creating reliable seals in critical systems like engines, transmissions, and fuel lines, where they are essential for maintaining performance, preventing leaks, and ensuring the long-term durability of the vehicle.

The core reason PTFE is so prevalent in automotive design is its unique versatility. It is one of the few materials that can reliably handle the aggressive chemical, thermal, and electrical demands of multiple vehicle systems simultaneously, from the engine block to the circuit board.

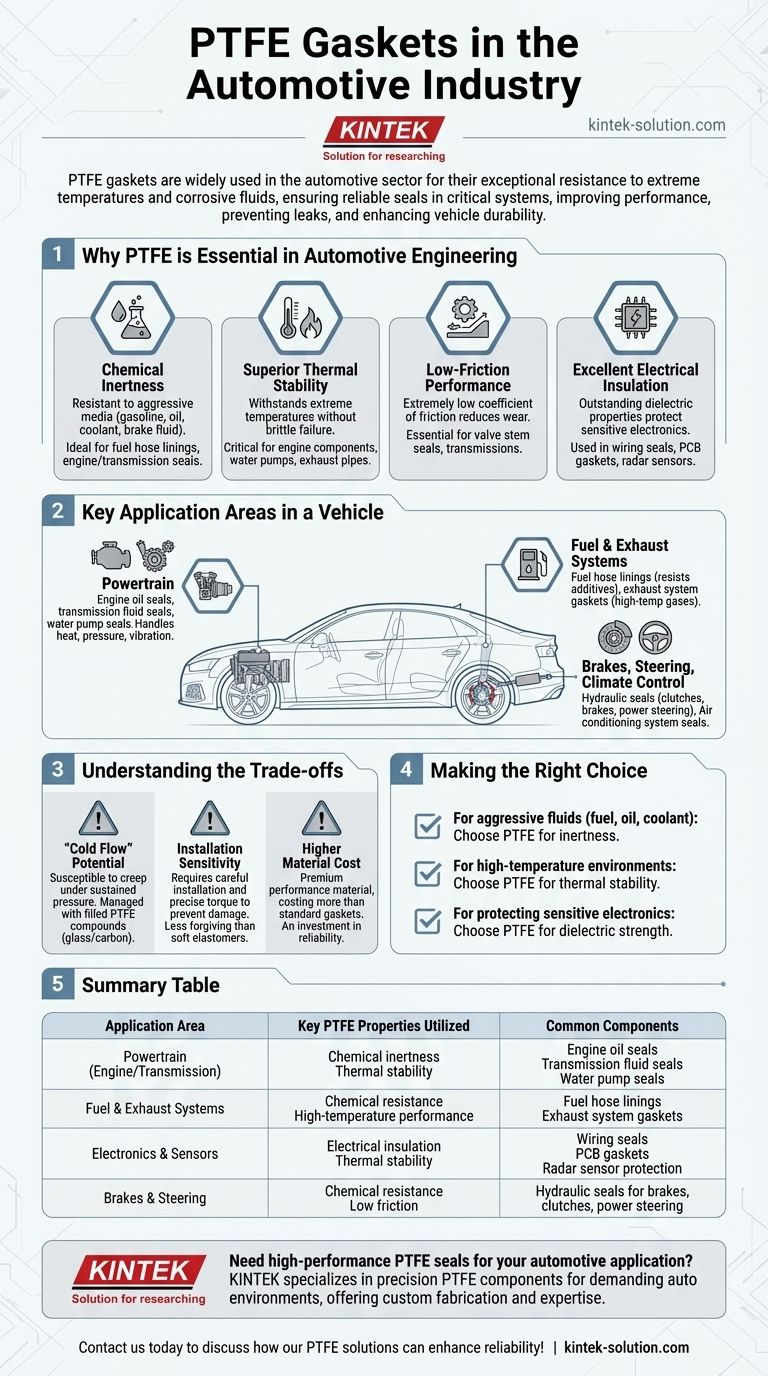

Why PTFE is Essential in Automotive Engineering

The harsh environment inside a modern vehicle—characterized by extreme heat, high pressure, and a cocktail of aggressive chemicals—demands materials that will not degrade. PTFE excels under these conditions for several key reasons.

Unmatched Chemical Inertness

A vehicle relies on numerous fluids, including gasoline, engine oil, coolant, and brake fluid. These are often considered aggressive media that can break down lesser materials.

PTFE is virtually inert to all of them. This property makes it the ideal choice for fuel hose linings, engine oil seals, and transmission fluid seals, preventing leaks and ensuring system integrity.

Superior Thermal Stability

Components in and around the engine and exhaust systems operate at extremely high temperatures.

PTFE gaskets maintain their structural integrity and sealing capability without becoming brittle or failing under this thermal stress, making them critical for engine components, water pumps, and exhaust pipes.

Low-Friction Performance

A key characteristic of PTFE is its extremely low coefficient of friction, one of the lowest of any solid material.

In applications with moving parts, such as valve stem seals or within transmissions, this low-friction surface reduces wear and tear, contributing to the longevity of the components it seals.

Excellent Electrical Insulation

Modern vehicles are complex electronic systems. Wires and sensors in the engine bay are exposed to the same heat and fluids as mechanical parts.

PTFE's outstanding dielectric properties make it a perfect insulator. It is used in wiring system sealing and as gaskets to protect sensitive electronic components like printed circuit boards (PCBs) and radar sensors.

Key Application Areas in a Vehicle

PTFE gaskets are not confined to one part of a car. They are specified across a wide range of systems where performance and reliability are non-negotiable.

The Powertrain: Engine and Transmission

This is the heart of the vehicle and a primary area for PTFE use. Applications include engine oil seals, transmission fluid seals, and seals for water pumps. They are responsible for containing fluids and pressure under constant heat and vibration.

The Fuel and Exhaust Systems

From the fuel tank to the tailpipe, PTFE provides a barrier against corrosive materials. It is used for fuel hose linings to resist degradation from fuel additives and as gaskets in the exhaust system to handle high-temperature gases.

Brakes, Steering, and Climate Control

High-pressure hydraulic systems require robust sealing. PTFE is used for hydraulic seals in clutches, brakes, and power steering systems. It is also found in air conditioning systems, where it must contain high-pressure refrigerants.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An advisor must be transparent about its limitations to ensure it is applied correctly.

Potential for "Cold Flow"

PTFE can be susceptible to creep, or "cold flow," where the material slowly deforms under sustained pressure. This is managed by using modified or filled PTFE compounds, which add materials like glass or carbon to improve rigidity for high-pressure applications.

Installation Sensitivity

Compared to softer, more forgiving elastomers, some PTFE gaskets require more careful installation. Over-tightening can damage the gasket and compromise the seal, so following precise torque specifications is critical.

Higher Material Cost

PTFE is a premium performance material and typically costs more than standard rubber or neoprene gaskets. Its use is an engineering decision to invest in reliability and longevity where operating conditions demand it.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the specific challenge you need to solve.

- If your primary focus is sealing aggressive fluids (fuel, oil, coolant): PTFE's chemical inertness makes it the most reliable choice for components like fuel system seals and engine gaskets.

- If your primary focus is high-temperature environments (engine block, exhaust): PTFE's thermal stability ensures a durable, long-lasting seal where other materials would quickly fail.

- If your primary focus is protecting sensitive electronics: PTFE's dielectric strength is essential for insulating wiring, sensors, and communication equipment from heat and fluid intrusion.

Ultimately, PTFE's unique combination of properties makes it an indispensable material for ensuring the performance, safety, and reliability of modern vehicles.

Summary Table:

| Application Area | Key PTFE Properties Utilized | Common Components |

|---|---|---|

| Powertrain (Engine/Transmission) | Chemical inertness, Thermal stability | Engine oil seals, Transmission fluid seals, Water pump seals |

| Fuel & Exhaust Systems | Chemical resistance, High-temperature performance | Fuel hose linings, Exhaust system gaskets |

| Electronics & Sensors | Electrical insulation, Thermal stability | Wiring seals, PCB gaskets, Radar sensor protection |

| Brakes & Steering | Chemical resistance, Low friction | Hydraulic seals for brakes, clutches, power steering |

Need high-performance PTFE seals for your automotive application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the demanding environments of the automotive, semiconductor, medical, and industrial sectors. Our expertise ensures your components meet rigorous standards for chemical resistance, thermal stability, and durability.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Contact us today to discuss how our PTFE solutions can enhance the reliability and longevity of your automotive systems!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments