At its core, PTFE (Polytetrafluoroethylene) gaskets and O-rings are used in industrial and marine operations as high-performance seals for critical equipment. They are chosen for their unique ability to create a reliable, leak-proof barrier in environments where other materials would quickly fail due to chemical corrosion, extreme temperatures, or constant wear. Their use spans from chemical processing plants and pharmaceutical labs to marine piping systems and heavy machinery.

The decision to use PTFE is fundamentally a decision for operational reliability. Its unparalleled resistance to chemicals and temperature extremes ensures system integrity, minimizes costly downtime, and enhances safety in the most demanding industrial settings.

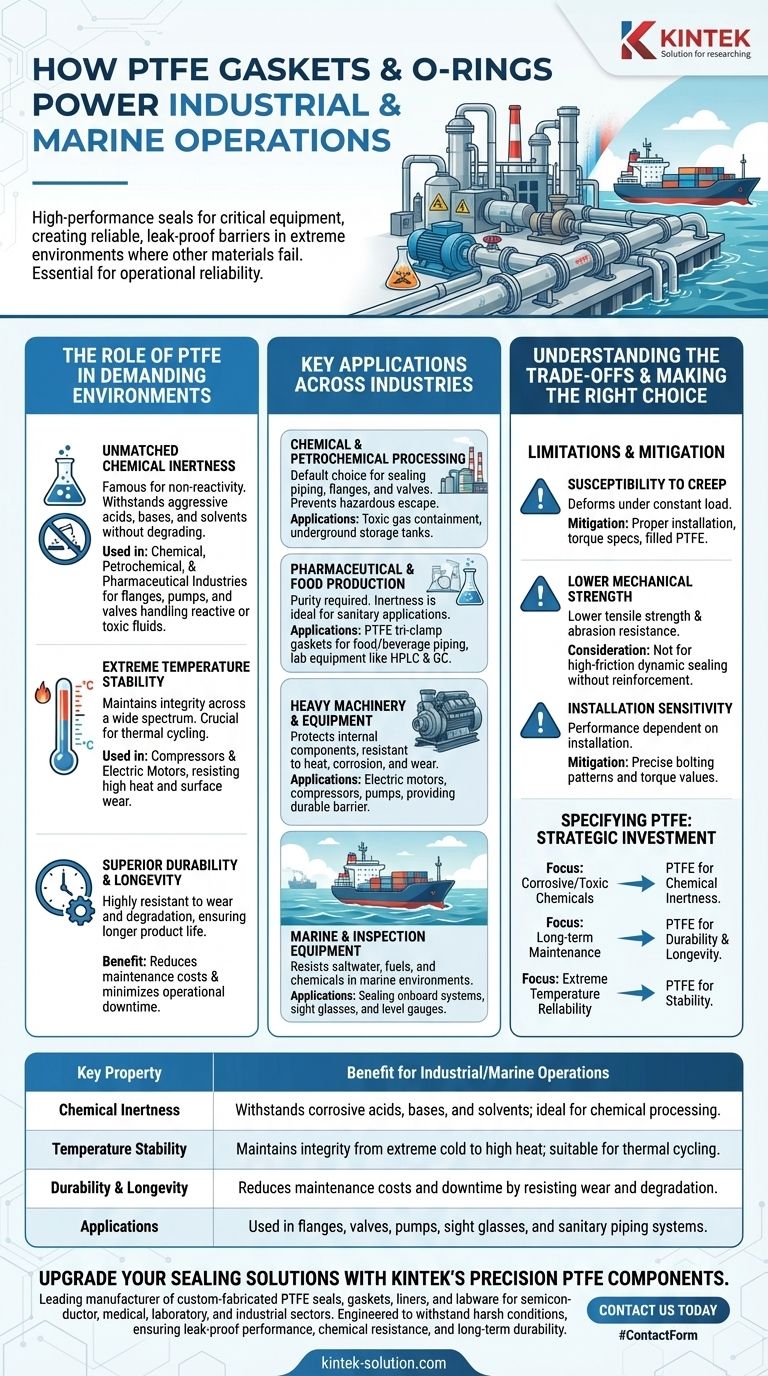

The Role of PTFE in Demanding Environments

The value of PTFE in gaskets and O-rings comes from a specific set of material properties that make it uniquely suited for harsh operational conditions. Understanding these properties explains why it has become a standard in so many critical industries.

Unmatched Chemical Inertness

PTFE is famously non-reactive. It can withstand exposure to a vast range of aggressive and corrosive substances, including strong acids, bases, and solvents, without degrading.

This makes it essential for the chemical, petrochemical, and pharmaceutical industries, where it is used to seal flanges, pumps, and valves that handle reactive or toxic fluids.

Extreme Temperature Stability

PTFE seals maintain their integrity and sealing capability across a wide temperature spectrum. This stability is crucial for equipment that experiences significant thermal cycling.

Applications like compressors and electric motors benefit from PTFE's ability to resist both high temperatures and surface wear, ensuring a long and reliable service life.

Superior Durability and Longevity

Gaskets and O-rings made from PTFE are highly resistant to wear and degradation, even under continuous use. This durability translates directly into a longer product life.

A longer lifespan means fewer replacements are needed, which significantly reduces maintenance costs and minimizes operational downtime for asset owners.

Key Applications Across Industries

PTFE's robust properties have led to its adoption in a wide array of critical applications where seal failure is not an option.

Chemical and Petrochemical Processing

In this sector, PTFE gaskets are the default choice for sealing piping systems, flanges, and valves. They provide tight, leak-proof connections that prevent the escape of hazardous materials.

They are also used in highly demanding systems like toxic gas containment and underground storage tanks, where extreme leakage protection is a top priority.

Pharmaceutical and Food Production

The purity of processes in these industries requires materials that will not contaminate the product. PTFE's inertness makes it ideal for these sanitary applications.

PTFE tri-clamp gaskets are standard for ensuring leak-proof, hygienic connections in piping systems used for food, beverage, and pharmaceutical manufacturing. It's also used in lab equipment like HPLC and GC systems.

Heavy Machinery and Equipment

PTFE seals protect the internal components of various types of machinery. Their resistance to heat, corrosion, and wear is vital for performance and reliability.

They are commonly found in electric motors, compressors, and pumps, where they provide a durable barrier against contaminants and fluid leaks.

Marine and Inspection Equipment

In marine environments, equipment is constantly exposed to saltwater, fuels, and chemicals. PTFE's corrosion resistance makes it an excellent choice for sealing various onboard systems.

It is also a preferred material for seals on sight glasses and level gauges, as it maintains performance and clarity over time despite exposure to harsh industrial fluids.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every scenario. Acknowledging its limitations is key to using it effectively.

Susceptibility to Creep

PTFE is a relatively soft material and can be prone to "creep" or "cold flow," where it slowly deforms over time under a constant load. This is a critical consideration in high-pressure flange applications.

Proper installation and torque specifications are essential to mitigate this. In some cases, filled PTFE grades (mixed with materials like glass or carbon) are used to improve creep resistance.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE has lower tensile strength and abrasion resistance. It is not suitable for dynamic sealing applications involving high friction or sharp surfaces without reinforcement.

Installation Sensitivity

The performance of a PTFE gasket is highly dependent on proper installation. Over-tightening a flange can crush the gasket, while under-tightening can lead to leaks.

Ensuring that technicians follow precise bolting patterns and torque values is crucial for achieving a reliable, long-lasting seal.

Making the Right Choice for Your Operation

Selecting the right sealing material is a critical engineering decision that impacts safety, cost, and efficiency. PTFE offers a powerful solution when used for the correct application.

- If your primary focus is containing corrosive or toxic chemicals: PTFE's unmatched chemical inertness makes it the safest and most reliable choice for sealing flanges, valves, and pumps.

- If your primary focus is minimizing long-term maintenance costs: The exceptional durability and long service life of PTFE reduce the frequency of replacement, directly lowering labor costs and operational downtime.

- If your primary focus is reliability in extreme temperatures: PTFE's ability to perform consistently in both high and low-temperature environments makes it ideal for critical machinery like compressors and process equipment.

Ultimately, specifying PTFE for gaskets and O-rings is a strategic investment in the long-term integrity and efficiency of your operation.

Summary Table:

| Key Property | Benefit for Industrial/Marine Operations |

|---|---|

| Chemical Inertness | Withstands corrosive acids, bases, and solvents; ideal for chemical processing and pharmaceutical applications. |

| Temperature Stability | Maintains integrity from extreme cold to high heat; suitable for compressors, motors, and thermal cycling equipment. |

| Durability & Longevity | Reduces maintenance costs and downtime by resisting wear and degradation over time. |

| Applications | Used in flanges, valves, pumps, sight glasses, and sanitary piping systems across various industries. |

Upgrade your sealing solutions with KINTEK's precision PTFE components.

As a leading manufacturer of high-performance PTFE seals, gaskets, liners, and labware, we understand the critical role reliable sealing plays in your operations. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE components are engineered to withstand the harshest conditions—ensuring leak-proof performance, chemical resistance, and long-term durability.

From prototypes to high-volume orders, we prioritize precision production to meet your exact specifications. Let us help you enhance safety, reduce downtime, and optimize efficiency.

Contact us today to discuss your specific sealing challenges and receive a customized solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs