PTFE bushes are highly engineered components whose design and manufacturing process is a direct response to specific application demands. They are designed by defining the required shape and material composition based on operating conditions and are manufactured by molding granular PTFE resin, which is created through a chemical process called suspension polymerization.

The key to understanding PTFE bushes is recognizing that they are not one-size-fits-all. Their production is a tailored process, starting with the synthesis of the raw polymer and culminating in a custom-molded and finished component with specific fillers chosen to enhance properties like strength and stability for a given environment.

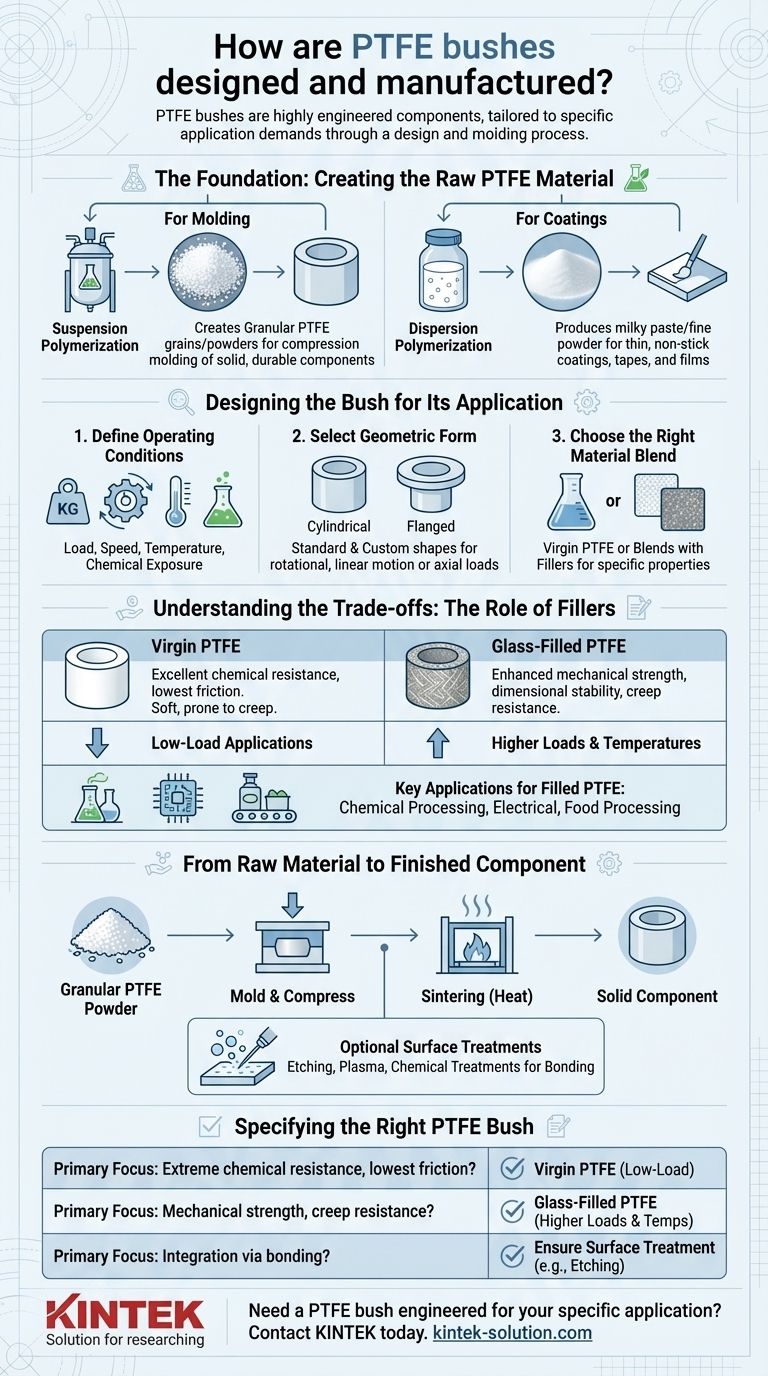

The Foundation: Creating the Raw PTFE Material

Before a bush can be molded, the Polytetrafluoroethylene (PTFE) polymer must be created. The method used directly determines the form of the raw material and its subsequent applications.

Suspension Polymerization for Molding

This is the primary method for producing the PTFE used in solid bushes. The process results in granular PTFE grains or powders.

These grains are the ideal raw material for compression molding, where they are fused under heat and pressure to form a solid, durable component.

Dispersion Polymerization for Coatings

This alternative method produces a milky paste or a very fine powder.

This form of PTFE is not suitable for molding solid parts. Instead, it is used for creating thin, non-stick coatings on surfaces or for producing tapes and films.

Designing the Bush for Its Application

The design phase is a collaborative process that translates performance requirements into a physical specification. Every aspect of the design is dictated by the environment in which the bush will operate.

Defining Operating Conditions

The process begins with an analysis of the client's needs. Factors like load, speed, temperature, and chemical exposure are critical inputs that guide all subsequent decisions.

Selecting the Geometric Form

PTFE bushes can be manufactured in a variety of standard and custom shapes to fit the mechanical assembly.

Common forms include simple cylindrical bushes for rotational or linear motion and flanged bushes which provide a bearing surface for axial loads. Custom shapes can be produced for unique requirements.

Choosing the Right Material Blend

Pure, or "virgin," PTFE is often modified with fillers to improve specific properties. Manufacturers offer various blends, sometimes equivalent to well-known commercial grades like Rulon.

This allows designers to select a material with a known performance profile for properties like wear resistance or load-bearing capacity.

Understanding the Trade-offs: The Role of Fillers

While virgin PTFE has excellent properties, its mechanical limitations often necessitate the use of fillers. Adding materials like glass fibers creates a composite with enhanced characteristics.

The Baseline: Virgin PTFE

Pure PTFE offers the lowest coefficient of friction and excellent chemical resistance. However, it is relatively soft and prone to "creep" or deforming under a sustained load.

Enhancing Performance with Glass Fillers

Adding glass fibers to the PTFE resin results in glass-filled PTFE. This significantly improves key mechanical properties.

These bushes offer increased dimensional stability, creep resistance, and overall mechanical strength compared to their virgin counterparts.

Key Applications for Filled PTFE

The superior properties of filled PTFE make it ideal for demanding industries. It is frequently used in chemical processing, electrical applications, and food processing where a combination of chemical resistance, low friction, and strength is essential.

From Raw Material to Finished Component

The final manufacturing stages transform the selected PTFE material into a precise, functional part.

The Molding Process

Granular PTFE powder is placed into a mold and compacted under high pressure. The component is then heated in a process called sintering, which fuses the particles together into a solid, homogenous part.

Optional Surface Treatments

For applications where the PTFE bush needs to be bonded to another surface, its naturally non-stick surface can be problematic.

Treatments like etching, plasma, or chemical treatments can be applied to modify the surface, dramatically improving its ability to adhere to adhesives.

Specifying the Right PTFE Bush

To select the correct component, you must align the material's properties with your primary engineering goal.

- If your primary focus is extreme chemical resistance and the lowest possible friction: Virgin PTFE is often the most suitable and cost-effective choice for low-load applications.

- If your primary focus is mechanical strength and creep resistance: Specify a glass-filled PTFE to handle higher loads and temperatures with greater dimensional stability.

- If your primary focus is integration via bonding: Ensure your specification includes a surface treatment like chemical etching to promote proper adhesion.

By understanding this interplay of material science, design, and manufacturing, you can confidently specify a PTFE bush that precisely meets the demands of your application.

Summary Table:

| Design & Manufacturing Stage | Key Considerations |

|---|---|

| Material Creation | Suspension polymerization produces granular PTFE for molding. |

| Design Phase | Based on load, speed, temperature, and chemical exposure. |

| Material Selection | Virgin PTFE for low friction; glass-filled for strength/stability. |

| Manufacturing Process | Compression molding and sintering of PTFE powder. |

| Post-Processing | Optional surface treatments (e.g., etching) for bonding. |

Need a PTFE bush engineered for your specific application?

At KINTEK, we specialize in the precision design and manufacturing of high-performance PTFE components, including seals, liners, and labware. Whether you require the superior chemical resistance of virgin PTFE or the enhanced strength and creep resistance of glass-filled PTFE, our experts will partner with you from prototype to high-volume production.

Contact us today to discuss your project requirements and discover how our custom fabrication capabilities can provide the perfect solution for your industry—be it semiconductor, medical, laboratory, or industrial.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some common fillers used in PTFE seal materials? Enhance Performance for Your Application

- What are the steps involved in the PTFE lining process? A Guide to Durable Chemical Resistance

- What are the three main factors to consider when selecting ball valve seat materials? Ensure System Reliability

- What was the final material selection decision? Choosing PEEK for High-Performance Ball Valve Seats

- What are the key properties of PTFE Teflon washers? Unlock Superior Chemical & Temperature Resistance

- What post-machining treatments are applied to Teflon parts? Stabilize and Clean, Don't Modify.

- What advantage does the low coefficient of friction of PTFE balls provide? Boost Durability and Efficiency

- What are the practical benefits of using PTFE components? Boost Reliability & Cut Costs in Harsh Environments