In the electronics industry, extruded PTFE is prized for one primary function. It serves as a superior electrical insulator for critical components. Its unique combination of excellent dielectric strength, high-temperature stability, and chemical inertness makes it indispensable for applications like insulating high-frequency wiring, protecting circuit boards, and in specialized semiconductor manufacturing processes.

The decision to use extruded PTFE rods in electronics is not just about electrical insulation; it's about ensuring that insulation remains stable and reliable under extreme thermal and chemical stress, a condition where many other materials would fail.

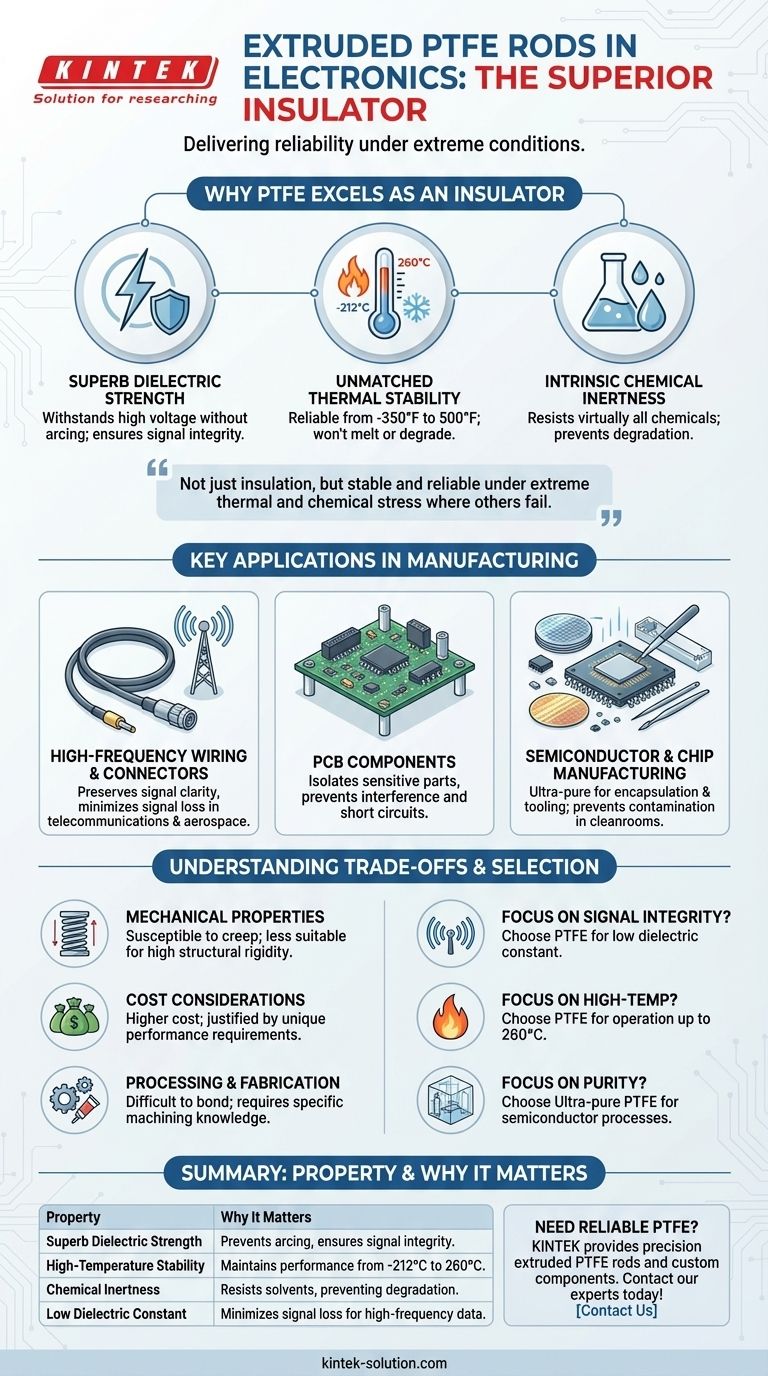

Why PTFE Excels as an Electrical Insulator

Polytetrafluoroethylene (PTFE) is not just another plastic. Its molecular structure gives it a set of properties that make it uniquely suited for demanding electrical and electronic applications where failure is not an option.

Superb Dielectric Strength

Dielectric strength is a material's ability to withstand a strong electric field without breaking down and conducting electricity.

PTFE possesses superb dielectric strength. This means it can be used to insulate components carrying high voltages without the risk of electrical arcing or short-circuiting, ensuring both safety and signal integrity.

Unmatched Thermal Stability

Electronic components can generate significant heat, and the environments they operate in can be extreme.

PTFE performs reliably across an exceptionally wide temperature range, from as low as -212°C (-350°F) up to 260°C (500°F). This stability ensures the insulator will not melt, degrade, or lose its properties when a component heats up.

Intrinsic Chemical Inertness

In manufacturing and operation, electronic components can be exposed to solvents, cleaning agents, and humidity.

PTFE is almost completely inert, meaning it resists virtually all industrial chemicals and solvents. This prevents degradation that could compromise the insulator's effectiveness over time.

Key Applications in Electronics Manufacturing

Extruded PTFE rods are machined into specific shapes to serve as insulators in several critical areas of the electronics industry.

High-Frequency Wiring and Connectors

In aerospace, telecommunications, and computer assemblies, preserving signal clarity is paramount.

PTFE is used as the insulating dielectric material in high-frequency coaxial cables and wiring harnesses. Its properties prevent signal loss and distortion, which is critical for high-speed data transmission.

Printed Circuit Board (PCB) Components

Components on a circuit board often require electrical isolation from each other and the board itself.

Small insulators, standoffs, and protective covers are machined from PTFE rods to isolate sensitive parts on a PCB, preventing electrical interference and short circuits.

Semiconductor and Chip Manufacturing

The fabrication of microchips is an ultra-clean process where any contamination can ruin an entire batch.

When manufactured to ultra-pure standards, PTFE is used for items like encapsulation devices for quartz heaters and other tooling within chip manufacturing facilities. Its inertness and purity prevent it from releasing contaminants.

Understanding the Trade-offs

While PTFE is a high-performance material, its selection requires a clear understanding of its limitations. It is not a universal solution for all applications.

Mechanical Properties

PTFE is a relatively soft material. It can be susceptible to "creep" or cold flow, meaning it can deform over time when subjected to a sustained compressive load.

This makes it less suitable for applications that require high structural rigidity or tight, unchanging tolerances under constant pressure.

Cost Considerations

High performance comes at a price. PTFE is significantly more expensive than common insulating commodity plastics like PVC or polyethylene.

Its use is therefore typically justified only in applications where its unique thermal, chemical, or dielectric properties are a hard requirement.

Processing and Fabrication

PTFE's low-friction surface makes it difficult to bond to other materials using conventional adhesives.

Machining it also requires specific knowledge to manage its softness and thermal expansion properties to achieve precise dimensions.

Making the Right Choice for Your Application

When selecting an insulator, your decision should be driven by the specific operational demands of the component.

- If your primary focus is high-frequency signal integrity: PTFE is an ideal choice due to its low dielectric constant, ensuring minimal signal loss in communications and data applications.

- If your primary focus is performance in high-temperature environments: PTFE's ability to operate reliably up to 260°C makes it a clear frontrunner over standard plastics that would fail.

- If your primary focus is chemical resistance and purity for sensitive processes: Ultra-pure PTFE is essential for applications like semiconductor manufacturing where contamination is not an option.

Ultimately, choosing extruded PTFE is an investment in long-term reliability for your most critical electronic systems.

Summary Table:

| Property | Why It Matters for Electronics |

|---|---|

| Superb Dielectric Strength | Prevents electrical arcing and ensures signal integrity in high-voltage applications. |

| High-Temperature Stability | Maintains performance from -212°C to 260°C, ideal for heat-generating components. |

| Chemical Inertness | Resists solvents and cleaners, preventing degradation in harsh environments. |

| Low Dielectric Constant | Minimizes signal loss, making it perfect for high-frequency data transmission. |

Need a reliable insulator for your critical electronic components?

KINTEK specializes in manufacturing precision extruded PTFE rods and custom-machined components for the semiconductor, medical, laboratory, and industrial sectors. We ensure the material purity and dimensional accuracy your high-performance applications demand, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance the reliability and performance of your electronic systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials