Yes, Teflon (PTFE) sheets can absolutely be used as a baking liner. They are designed as a reusable, durable, and highly non-stick alternative to single-use options like parchment paper or aluminum foil for lining baking sheets and pans.

While PTFE sheets offer superior reusability and non-stick performance for most baking tasks, their primary limitation is a strict temperature ceiling. Understanding and respecting this limit is the single most important factor for using them safely and effectively.

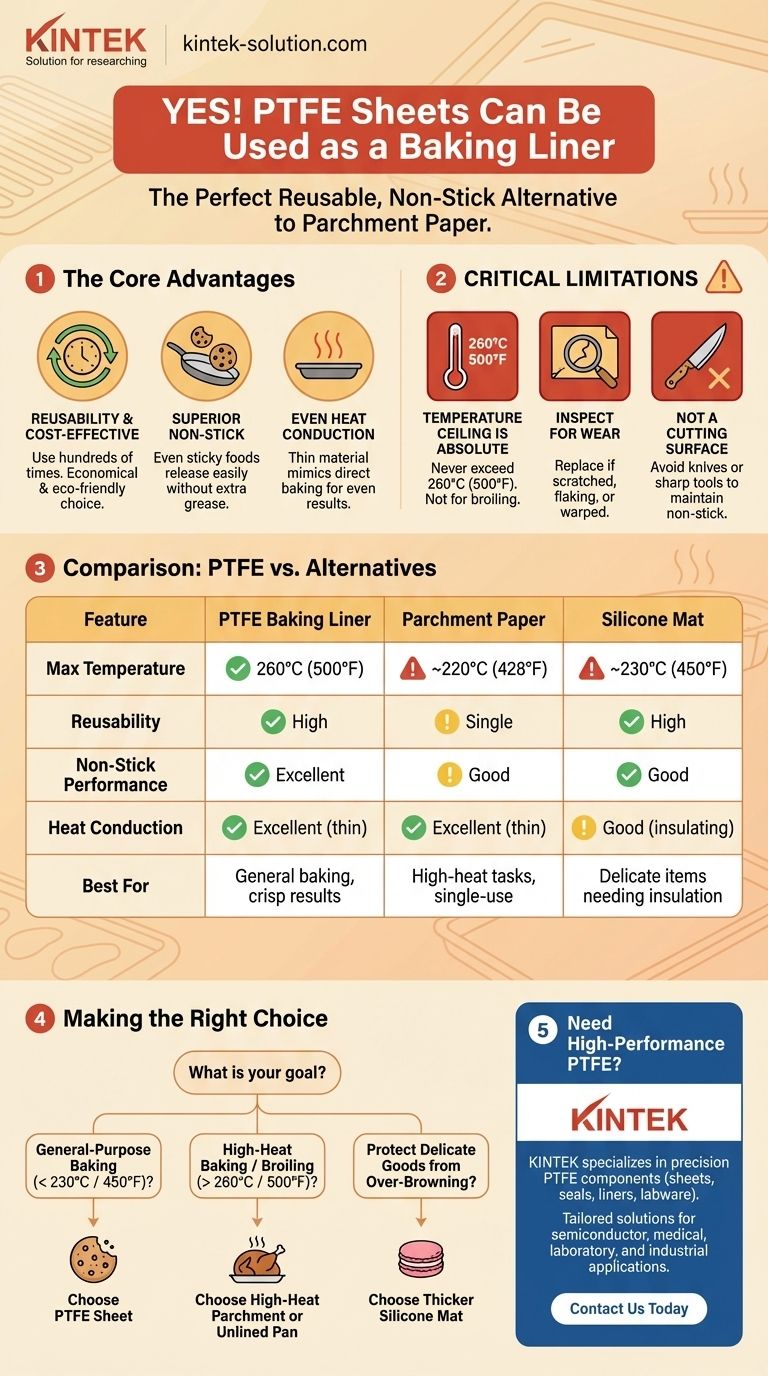

The Core Advantages of PTFE Baking Liners

PTFE, commonly known by the brand name Teflon, provides distinct benefits that make it an attractive option for frequent bakers.

Reusability and Cost-Effectiveness

A single PTFE sheet can be washed and reused hundreds, if not thousands, of times. This makes it a significantly more economical and environmentally friendly choice over the long term compared to disposable parchment paper.

Superior Non-Stick Performance

PTFE has one of the lowest coefficients of friction of any solid material. This means even the stickiest baked goods, like cheesy dishes or sugary cookies, will release with exceptional ease, often without needing any extra grease.

Even Heat Conduction

These liners are typically very thin, allowing heat to transfer from the pan to your food efficiently and evenly. Unlike thicker silicone mats which can insulate, PTFE liners more closely mimic the direct baking results you get from parchment paper.

Understanding the Critical Limitations

To use PTFE liners correctly, you must be aware of their operational boundaries. These are not suggestions; they are requirements for safe use.

The Temperature Ceiling is Absolute

The most critical limitation is heat. PTFE begins to degrade at temperatures above 260°C (500°F). You should never use these liners for applications like broiling or in ovens operating above this temperature. Most standard baking (e.g., cookies, cakes, roasting vegetables) occurs well below this limit.

Inspect for Wear and Tear

While durable, these sheets are not indestructible. You must inspect them regularly for signs of physical breakdown, such as deep scratches, flaking, discoloration, or warping. If the surface is compromised, it's time to replace the liner.

Not a Cutting Surface

Never use a knife or sharp pizza cutter directly on the PTFE liner. The surface is easily damaged, which will ruin its non-stick properties and could cause small particles to flake off.

How to Choose: PTFE vs. Other Liners

Understanding how PTFE compares to common alternatives helps clarify its ideal use case.

Compared to Parchment Paper

PTFE is essentially a reusable version of parchment paper. It provides the same thin barrier and direct heat transfer but with the added benefits of durability and long-term cost savings.

Compared to Silicone Mats

Silicone mats are much thicker and offer more insulation. This can be beneficial for preventing bottoms from burning on delicate items like macarons, but it can also hinder browning and crisping. PTFE's thinness makes it better for tasks where a crisp bottom is desired.

Making the Right Choice for Your Baking

Use your primary goal to determine the best liner for the job.

- If your primary focus is general-purpose baking below 230°C (450°F): A PTFE sheet is an excellent, cost-effective, and eco-friendly replacement for parchment paper.

- If your primary focus is high-heat baking or broiling: You must use high-heat-rated parchment paper or an unlined pan, as PTFE is not safe at these temperatures.

- If your primary focus is protecting delicate baked goods from over-browning: A thicker silicone mat may provide the insulation you need more effectively than a thin PTFE sheet.

By understanding its distinct advantages and absolute limitations, you can confidently integrate a PTFE liner as a reliable tool in your kitchen.

Summary Table:

| Feature | PTFE Baking Liner | Parchment Paper | Silicone Mat |

|---|---|---|---|

| Max Temperature | 260°C (500°F) | ~220°C (428°F) | Varies, often ~230°C (450°F) |

| Reusability | High (hundreds of uses) | Single-use | High |

| Non-Stick Performance | Excellent | Good | Good |

| Heat Conduction | Excellent (thin) | Excellent (thin) | Good (insulating) |

| Best For | General baking, crisp results | High-heat tasks, single-use | Delicate items needing insulation |

Need High-Performance PTFE Components for Your Application?

KINTEK specializes in manufacturing precision PTFE components, including custom sheets, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide durable, non-stick solutions tailored to your exact requirements—from prototypes to high-volume production.

Contact us today to discuss how our PTFE expertise can enhance your product performance and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries