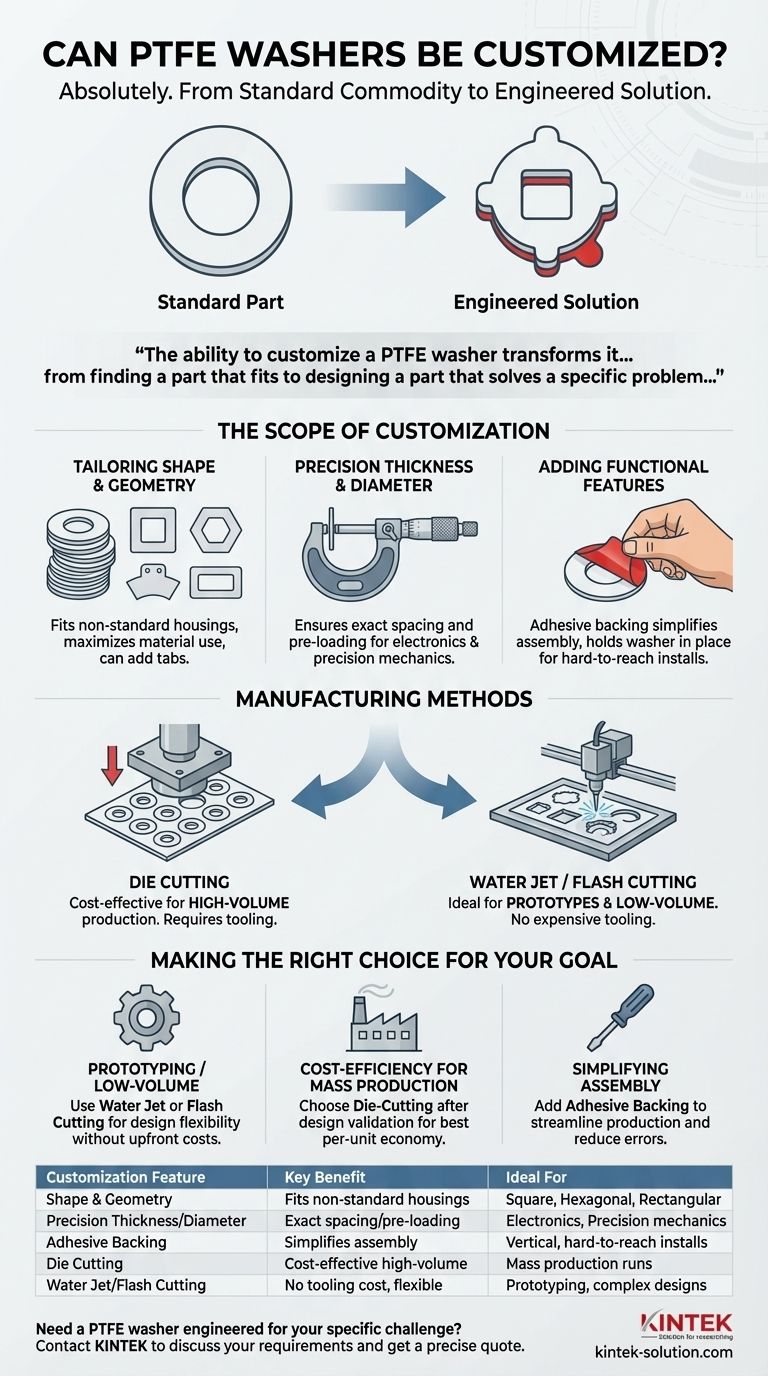

Absolutely. PTFE washers are not limited to standard, off-the-shelf sizes; they can be custom-manufactured to meet highly specific application requirements. This customization extends beyond simple dimensions and thickness to include unique shapes and functional additions like adhesive backings.

The ability to customize a PTFE washer transforms it from a simple commodity component into a precisely engineered solution. The focus shifts from finding a part that fits to designing a part that solves a specific problem related to spacing, sealing, or friction.

Beyond Standard Dimensions: The Scope of Customization

While standard sizes are readily available, many engineering applications demand specifications that fall outside these norms. True customization allows for the optimization of a component for its exact purpose.

Tailoring Shape and Geometry

The most common customization is moving beyond the standard circular shape. Washers can be produced in square, hexagonal, or rectangular forms.

This is often done to maximize material usage from a sheet or to fit into a non-circular housing where a round washer would leave gaps or fail to seat correctly.

Features like tabs can also be added to a washer's geometry, though the inherently low friction of PTFE often makes such anti-rotation features less effective than with other materials.

Precision Thickness and Diameter

Many applications in electronics or precision mechanics require exact spacing or pre-loading of components.

Custom manufacturing allows for the creation of washers with highly specific thicknesses and diameters to meet tight tolerances that standard parts cannot achieve.

Adding Functional Features

A common and highly effective customization is the addition of an adhesive backing to one side of the washer.

This simple feature dramatically simplifies assembly by holding the washer in place, which is especially valuable in vertical or hard-to-reach installations. It turns the washer into an integrated part of the assembly process.

How Custom PTFE Washers Are Made

The manufacturing method used depends on the complexity of the design, the required precision, and the production volume.

Die Cutting

For high-volume production of a specific custom shape, die cutting is the most cost-effective method. A steel die is created to stamp out identical washers from a sheet of PTFE.

Water Jet and Flash Cutting

For prototypes, low-volume runs, or highly complex geometries, methods like water jet cutting or flash cutting are ideal.

These processes use a high-pressure stream of water or a CNC-guided blade to cut the washers from sheet material without the need for expensive custom tooling.

Understanding the Trade-offs

Customization provides an engineered solution but involves practical considerations that differ from using standard components.

Cost vs. Volume

Custom washers will almost always have a higher per-unit cost than their standard counterparts, especially in small quantities.

The initial cost of creating a die or the machine time for water jet cutting must be factored in. For high-volume runs, the per-unit cost of die-cutting becomes highly economical.

Lead Time

Unlike off-the-shelf parts that can ship immediately, custom washers require manufacturing time. This lead time must be incorporated into project schedules.

Making the Right Choice for Your Goal

Selecting the right approach depends entirely on your project's specific needs and constraints.

- If your primary focus is prototyping or a low-volume run: Water jet or flash cutting provides maximum design flexibility without the high upfront cost of tooling.

- If your primary focus is cost-efficiency for mass production: Die-cutting is the superior choice once your design has been finalized and validated.

- If your primary focus is simplifying assembly and reducing errors: Consider adding functional features like an adhesive backing to streamline your production process.

Ultimately, custom PTFE washers offer a powerful way to solve unique engineering challenges when a standard part is not sufficient.

Summary Table:

| Customization Feature | Key Benefit | Ideal For |

|---|---|---|

| Shape & Geometry | Fits non-standard housings, maximizes material use | Square, hexagonal, or rectangular housings |

| Precision Thickness/Diameter | Ensures exact spacing and pre-loading | Electronics, precision mechanics |

| Adhesive Backing | Simplifies assembly, holds washer in place | Vertical or hard-to-reach installations |

| Die Cutting | Cost-effective for high-volume production | Mass production runs |

| Water Jet/Flash Cutting | No tooling cost, ideal for prototypes/complex shapes | Prototyping, low-volume, complex designs |

Need a PTFE washer engineered for your specific challenge?

At KINTEK, we don't just supply parts; we provide solutions. Our expertise in custom fabricating PTFE components—from seals and liners to specialized labware—ensures you get a washer that solves your problem, not just one that fits.

We specialize in serving the semiconductor, medical, laboratory, and industrial sectors with precision production, from initial prototypes to high-volume orders.

Contact our engineering team today to discuss your custom PTFE washer requirements and get a precise quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability