Yes, PTFE bushings are specifically designed to operate without any external lubrication. Their material composition, centered on Polytetrafluoroethylene (PTFE), is inherently self-lubricating. This single characteristic is the source of their primary benefits, enabling reliable performance in applications where traditional lubricated bearings would be impractical, fail prematurely, or introduce contamination.

The core advantage of a PTFE bushing is not just that it can run without lubrication, but that it's engineered to excel because of it. This eliminates maintenance, reduces friction, and allows for robust operation in extreme environments where lubricants are a liability.

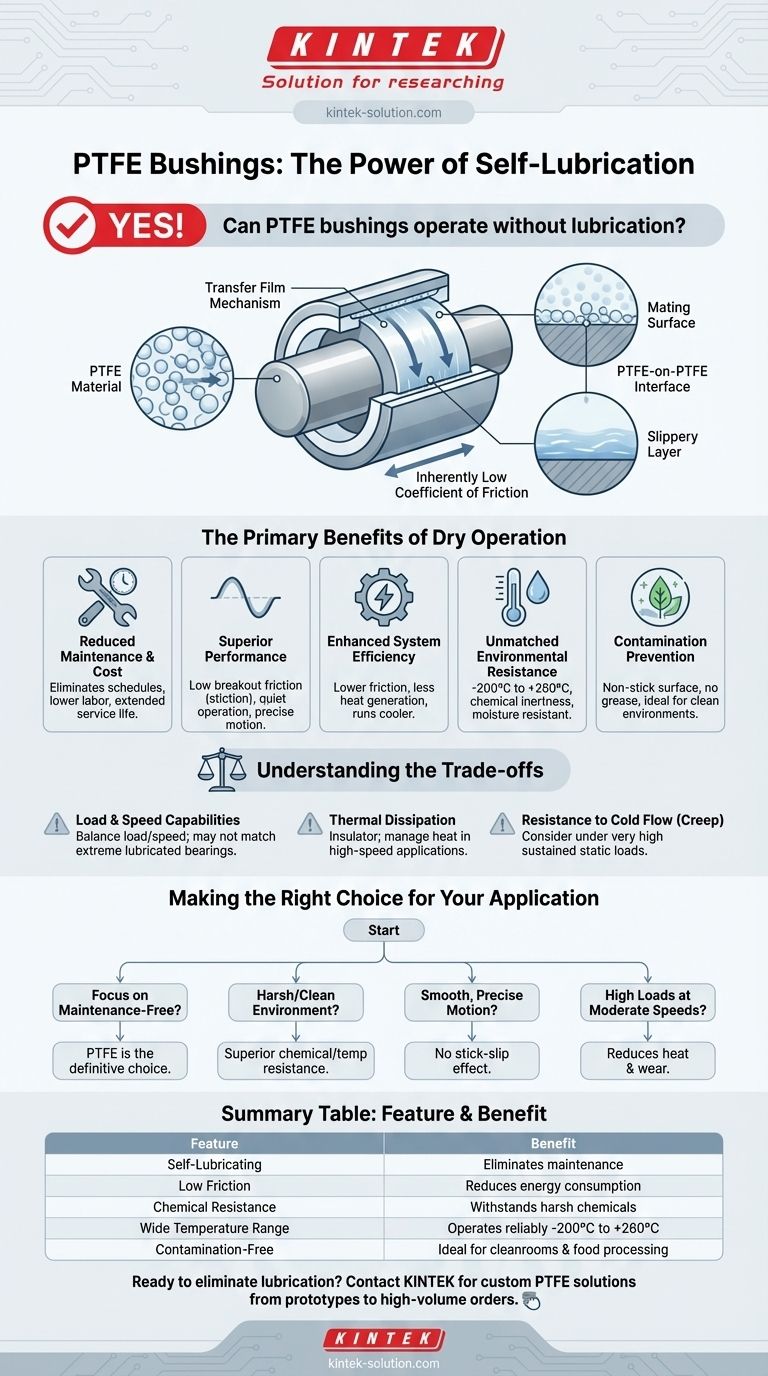

How Self-Lubrication in PTFE Works

The ability of a PTFE bushing to operate dry is not magic; it is a result of the material's fundamental molecular structure and how it interacts with a mating surface.

The Transfer Film Mechanism

When a shaft first rotates within a PTFE bushing, a thin, almost invisible layer of the PTFE material transfers from the bushing to the shaft's surface. This process creates an ideal PTFE-on-PTFE sliding interface. From this point on, the shaft is no longer rubbing against the bushing but against this self-deposited lubricating film.

Inherently Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This property minimizes the energy required to initiate and sustain motion, which directly translates to higher efficiency and less heat generation.

The Primary Benefits of Dry Operation

Eliminating the need for grease or oil creates a cascade of operational and design advantages that extend far beyond simple convenience.

Reduced Maintenance and Lifetime Cost

The most obvious benefit is the complete removal of lubrication schedules. This means no re-greasing, reduced downtime for maintenance, and lower labor costs over the life of the equipment. The service life of the application is often extended as a result.

Superior Performance Characteristics

PTFE bushings provide exceptionally low breakout friction, also known as stiction. This means very little force is needed to start a movement from a standstill, which is critical for applications requiring precise, smooth, and repeatable motion without any "stick-slip" effect. They also operate very quietly.

Enhanced System Efficiency

Lower friction means less energy is wasted as heat. In high-load applications, this efficiency is crucial for maintaining performance and preventing thermal damage to the system. The bushing itself helps the system run cooler and more efficiently.

Unmatched Environmental Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. It does not absorb moisture and is highly resistant to environmental degradation. Furthermore, it operates reliably across a massive temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Contamination Prevention

The non-stick surface of PTFE prevents contamination and facilitates easy cleaning. Because there is no grease or oil to attract dirt, dust, and debris, these bushings are an ideal choice for clean environments like food processing, medical devices, and electronics manufacturing.

Understanding the Trade-offs

While highly versatile, PTFE bushings are not the universal solution for every bearing application. Understanding their limitations is key to using them effectively.

Load and Speed Capabilities

While PTFE bushings offer high load-carrying capacity for a polymer, they may not match the extreme load ratings of some specialized, lubricated metallic bearings. Their performance is a balance between load, speed, and temperature, and they must be selected within their specified operational limits to ensure a long wear life.

Thermal Dissipation

PTFE is an excellent thermal and electrical insulator. While its low friction reduces heat generation, its insulating nature means it does not dissipate heat as effectively as a metal bearing. In very high-speed applications, this can lead to heat buildup if not managed through proper design.

Resistance to Cold Flow (Creep)

Cold flow, or creep, is the tendency of a material to deform under sustained pressure. While modern PTFE composites are specifically engineered with fillers to provide excellent cold flow resistance, it remains a consideration in applications involving very high static loads for extended periods.

Making the Right Choice for Your Application

Selecting the right bearing requires matching its core strengths to your primary operational goal.

- If your primary focus is maintenance-free operation: PTFE is the definitive choice, as it eliminates the entire lifecycle of purchasing, applying, and cleaning lubricants.

- If your application is in a harsh or clean environment: The material's extreme chemical, moisture, and temperature resistance makes it far superior to greased bearings that would fail or cause contamination.

- If your goal is smooth, precise motion: The exceptionally low stiction of PTFE ensures there is no stick-slip effect, providing the smoothest possible actuation from a complete stop.

- If you are managing high loads at moderate speeds: The self-lubricating properties reduce heat generation and wear, extending the service life of your equipment where a greased bearing might overheat.

By understanding these principles, you can confidently determine where a self-lubricating PTFE bushing is not just a replacement, but a significant engineering upgrade.

Summary Table:

| Feature | Benefit |

|---|---|

| Self-Lubricating | Eliminates maintenance schedules and external lubricants. |

| Low Friction | Reduces energy consumption and prevents stick-slip motion. |

| Chemical Resistance | Withstands harsh chemicals and solvents. |

| Wide Temperature Range | Operates reliably from -200°C to +260°C (-328°F to +500°F). |

| Contamination-Free | Ideal for cleanrooms, food processing, and medical devices. |

Ready to eliminate lubrication and maintenance from your application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom bushings. Our expertise ensures your parts are engineered for reliability in the most demanding semiconductor, medical, laboratory, and industrial environments.

We offer custom fabrication from prototypes to high-volume orders. Contact our experts today to discuss how our PTFE solutions can enhance your equipment's performance and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs