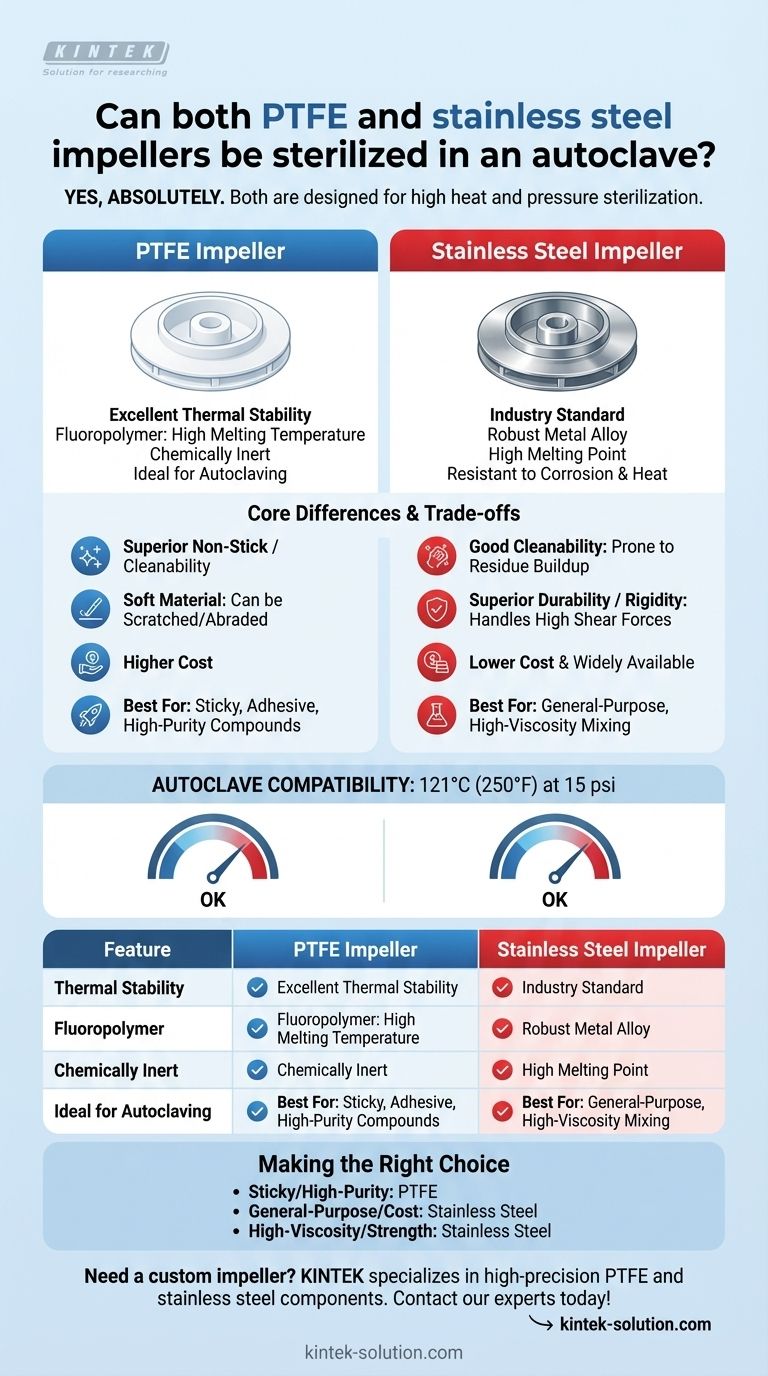

Yes, absolutely. Both PTFE and stainless steel impellers are fully capable of withstanding the high heat and pressure of standard autoclave sterilization cycles. The materials are selected for their thermal stability and chemical resistance, making them suitable for sterile applications.

The decision between PTFE and stainless steel is not about their ability to be autoclaved, but about their performance characteristics. Your choice should be guided by the specific substances you are mixing and your operational priorities, such as cleaning efficiency versus cost.

Autoclave Compatibility: A Deeper Look

Both materials handle the typical conditions of an autoclave (121°C / 250°F at 15 psi) with ease due to their fundamental properties.

Why Stainless Steel Excels

Stainless steel is a robust metal alloy with a very high melting point. It is the industry standard for sterile equipment due to its proven durability, strength, and resistance to corrosion and heat.

Why PTFE Excels

PTFE (Polytetrafluoroethylene) is a fluoropolymer known for its exceptionally high melting temperature and thermal stability. Its inherent chemical inertness and ability to withstand high temperatures make it perfectly suited for autoclaving.

Understanding the Core Differences

While both can be sterilized, their performance in a laboratory or production setting differs significantly. The right choice depends entirely on your application's specific demands.

Cleanability and Non-Stick Properties

This is the most critical distinction. PTFE is famously non-stick, which drastically simplifies cleaning and reduces the risk of cross-contamination between batches.

Stainless steel, while generally easy to clean, can be prone to residue buildup when working with moderately to highly adhesive compounds. This can complicate cleaning validation in sensitive processes.

Durability and Physical Strength

Stainless steel is far superior in terms of rigidity and physical durability. It can withstand higher shear forces and is resistant to physical damage if mishandled.

PTFE is a much softer material. It can be scratched or abraded more easily and may not be suitable for high-viscosity mixing that exerts significant physical stress on the impeller.

The Practical Trade-offs

Beyond performance, practical considerations like cost and availability often drive the final decision.

Cost and Sourcing

Stainless steel impellers are significantly cheaper and more widely available than their PTFE counterparts.

The unique properties of PTFE often justify its higher cost, but it may require more effort to source the specific size and style you need.

Variety and Options

Because it is the industry standard, stainless steel is available in a much wider array of styles and sizes. Finding the perfect impeller geometry for a standard application is typically easier with stainless steel.

Making the Right Choice for Your Application

Selecting the correct material is crucial for ensuring the integrity and efficiency of your sterile process.

- If your primary focus is general-purpose use and cost-effectiveness: Choose stainless steel. It is the reliable, economical workhorse for a vast range of applications.

- If you are working with sticky, adhesive, or high-purity biological compounds: The superior non-stick properties and cleanability of PTFE are worth the investment to ensure purity.

- If your primary focus is mechanical strength for high-viscosity mixing: Stainless steel's rigidity makes it the only viable option.

Ultimately, choosing the right impeller material is a key step in safeguarding the success of your work.

Summary Table:

| Feature | PTFE Impeller | Stainless Steel Impeller |

|---|---|---|

| Autoclave Sterilizable | Yes (Excellent thermal stability) | Yes (Industry standard) |

| Chemical Resistance | Excellent | Very Good |

| Non-Stick / Cleanability | Superior (Ideal for sticky compounds) | Good (Prone to residue buildup) |

| Durability / Rigidity | Soft (Can be scratched/abraded) | Superior (Handles high shear forces) |

| Cost | Higher | Lower (Cost-effective) |

| Best For | Sticky, adhesive, high-purity compounds | General-purpose, high-viscosity mixing |

Need a custom impeller for your sterile process?

At KINTEK, we specialize in manufacturing high-precision PTFE and stainless steel components for the semiconductor, medical, and laboratory industries. Whether you need the non-stick purity of a PTFE impeller or the robust strength of a stainless steel one, we provide custom fabrication from prototypes to high-volume orders to ensure your process integrity.

Contact our experts today to discuss your specific application requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability