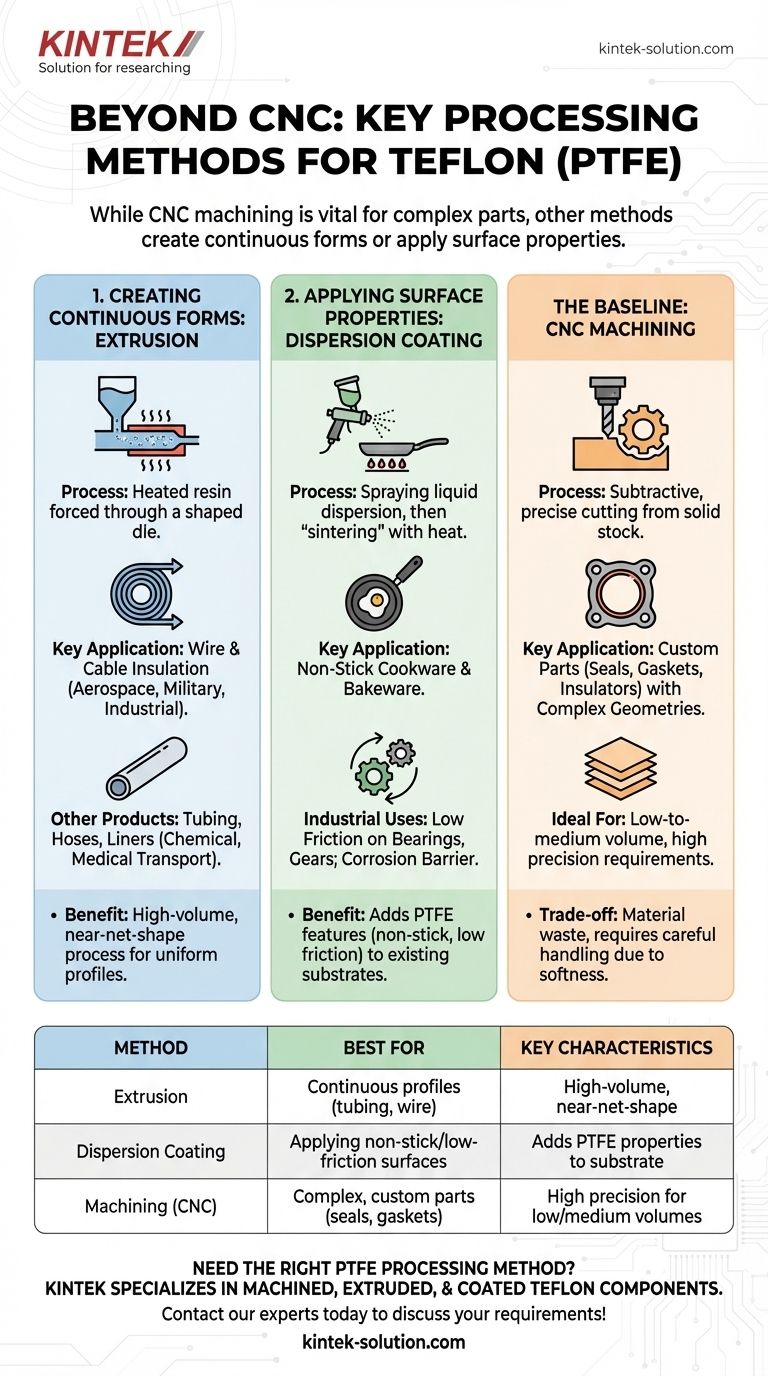

Beyond CNC machining, the most common processing methods for Teflon (PTFE) involve turning it into continuous forms through extrusion or applying it as a surface treatment through dispersion coating. These methods are chosen when the goal is not to create a complex, discrete part from a solid block, but rather to leverage Teflon's properties for applications like electrical insulation or non-stick surfaces.

The processing method for Teflon is fundamentally dictated by the final product's required form. While machining carves solid stock into components, other methods like extrusion and coating are designed to create continuous profiles or apply surface properties to existing objects.

Machining: The Baseline for Comparison

While you asked for methods besides CNC machining, understanding its role provides a crucial baseline. Machining is a subtractive process used to create precise, custom-designed parts from solid blocks, rods, or sheets of Teflon.

When Machining is Used

This method is ideal for producing low-to-medium volume parts with complex geometries, such as seals, gaskets, insulators, bearings, and valve components. It offers high precision and design flexibility.

Inherent Machining Challenges

Teflon’s unique properties, such as its softness and poor thermal conductivity, present challenges. Effective machining requires extremely sharp tools, proper heat management with coolants, and careful clamping to prevent the material from deforming or smearing.

Creating Continuous Forms: Extrusion

Extrusion is a high-volume manufacturing process used to create parts with a fixed, continuous cross-sectional profile. It is a fundamentally different approach from the subtractive nature of machining.

The Extrusion Process

In this process, granular or powdered Teflon resin is heated and forced through a shaped die. As the material cools, it solidifies into a continuous shape, which can be cut to any desired length.

Key Application: Wire and Cable Insulation

One of the most significant uses for extruded Teflon is electrical insulation. Its exceptional dielectric properties and high-temperature resistance make it a superior choice for insulating wires and cables in demanding aerospace, military, and industrial applications.

Other Extruded Products

Beyond wire insulation, extrusion is used to create Teflon tubing, hoses, and liners. These products are invaluable in the chemical and medical industries for transporting corrosive fluids, thanks to Teflon's extreme chemical inertness.

Applying Surface Properties: Dispersion Coating

Dispersion coating is a method for applying a thin layer of Teflon onto the surface of another material, imparting Teflon's signature properties to the substrate.

The Coating Process

This technique involves spraying a liquid dispersion containing fine Teflon particles onto a prepared surface. The object is then heated in a process called sintering, which fuses the particles into a solid, durable, non-stick film.

Key Application: Non-Stick Cookware

The most universally recognized application of this technology is in non-stick pans and bakeware. The Teflon coating creates a low-friction surface that prevents food from sticking and simplifies cleaning.

Industrial and Technical Coatings

In industrial settings, dispersion coatings are used to reduce friction on bearings, gears, and other moving parts. They also provide a corrosion-resistant barrier for equipment used in harsh chemical environments.

Understanding the Trade-offs

Choosing the right processing method is not about which is "best," but which is most appropriate for the intended function and form. Each method comes with distinct advantages and limitations.

Form Dictates Method

The final shape of the product is the primary decision driver. If you need a complex, three-dimensional gear, you must machine it. If you need 1,000 feet of uniform tubing, extrusion is the only logical choice.

Material Efficiency and Cost

Machining is a subtractive process that generates material waste (swarf). For high-volume production of simple profiles, extrusion is far more cost-effective and materially efficient as it is a near-net-shape process.

Function: A Component vs. a Feature

Machining creates a standalone Teflon component. In contrast, coating adds a Teflon feature (like non-stick or low friction) to a component made from another material, such as metal. The goal is to enhance an existing object, not create a new one from scratch.

How to Apply This to Your Project

Your application's specific requirements will clearly point to the correct manufacturing process.

- If your primary focus is a discrete, custom-shaped component: Machining from solid stock is your primary and most flexible method.

- If your primary focus is a long, continuous product like tubing or sheathing: Extrusion is the most efficient and appropriate industrial process.

- If your primary focus is to impart Teflon's properties onto another material's surface: Dispersion coating is the specific technique designed for this purpose.

Understanding these distinct processing paths is the key to leveraging Teflon's unique properties effectively for your specific engineering challenge.

Summary Table:

| Method | Best For | Key Characteristics |

|---|---|---|

| Extrusion | Continuous profiles (tubing, wire insulation) | High-volume, near-net-shape process |

| Dispersion Coating | Applying non-stick/low-friction surfaces | Adds PTFE properties to a substrate |

| Machining (CNC) | Complex, custom parts (seals, gaskets) | High precision for low-to-medium volumes |

Need the right PTFE processing method for your project?

At KINTEK, we specialize in manufacturing high-performance PTFE components. Whether your project requires precision-machined parts from solid stock, custom-extruded profiles, or specialized coatings, our expertise ensures your application leverages Teflon's properties effectively.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications