Yes, while Polytetrafluoroethylene (PTFE) is famous for its near-universal chemical inertness, there are a few specific substances that can cause severe degradation. The most notable exceptions are molten alkali metals (like sodium), elemental fluorine gas, and certain highly reactive fluorinating compounds, particularly under conditions of high temperature and pressure.

The core principle to understand is that PTFE's exceptional resistance comes from its strong, stable carbon-fluorine bonds. The few chemicals that can attack it are those reactive enough to break these bonds, a process that is almost always enabled by extreme operating conditions.

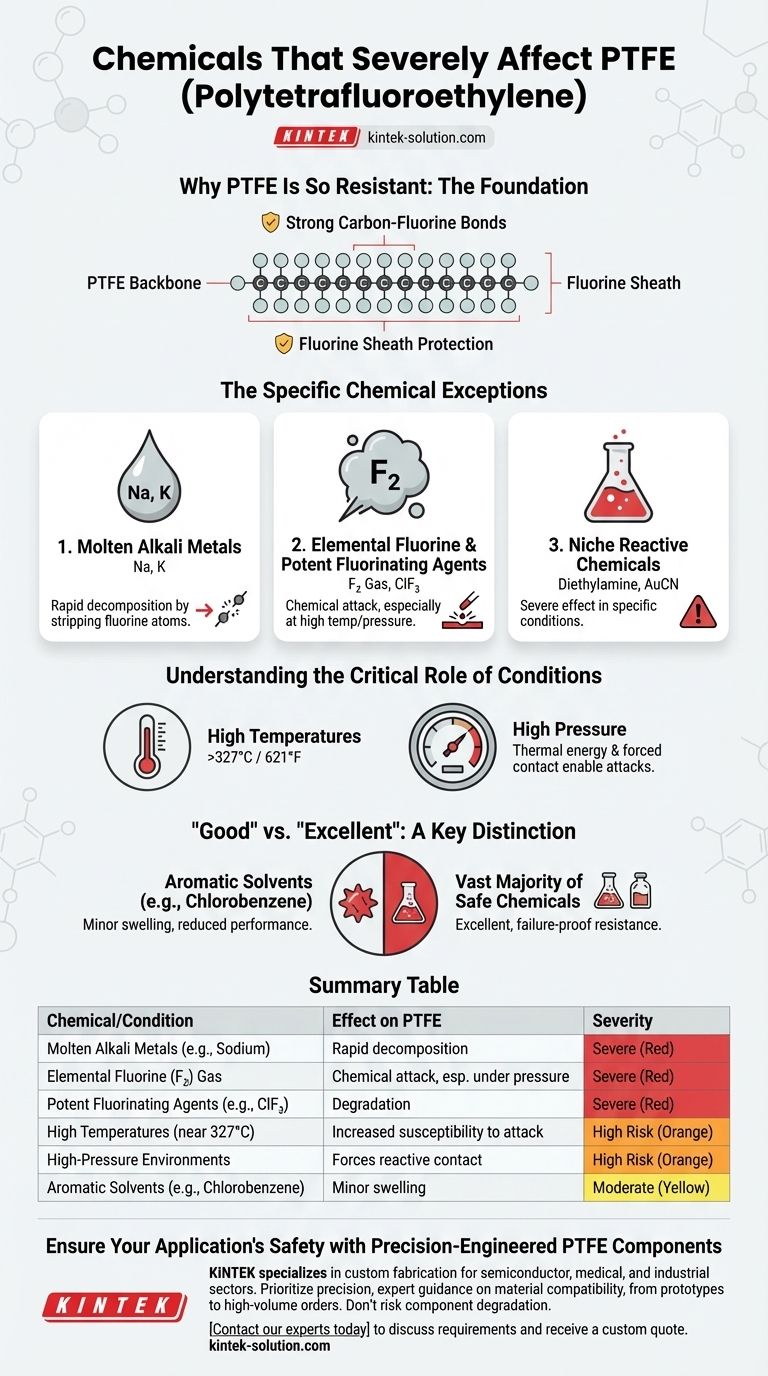

Why PTFE Is So Resistant: The Foundation

PTFE's chemical inertness is not magic; it's a result of its molecular structure. It consists of a long chain of carbon atoms completely shielded by a sheath of fluorine atoms.

The Carbon-Fluorine Bond

The bond between carbon and fluorine is one of the strongest single bonds in organic chemistry. This inherent strength makes the polymer chain extremely stable and difficult to break apart through chemical reaction.

The Fluorine Sheath

The fluorine atoms are larger than the carbon atoms they are bonded to, creating a dense, protective barrier around the carbon backbone. This "fluorine sheath" physically prevents most chemicals from even reaching the more vulnerable carbon chain.

The Specific Chemical Exceptions

Despite its robust structure, a handful of highly reactive substances possess the unique chemical properties needed to attack PTFE.

Molten Alkali Metals

Substances like molten or dissolved sodium and potassium are powerful reducing agents. They have the ability to strip fluorine atoms away from the polymer backbone, causing a rapid decomposition of the material.

Elemental Fluorine and Potent Fluorinating Agents

It is a chemical truism that "like dissolves like." Highly reactive fluorinating agents are the natural enemy of a fluoropolymer like PTFE.

These include elemental fluorine (F₂) gas, chlorine trifluoride (ClF₃), and other rare compounds like xenon difluoride. They can attack the polymer, especially at elevated temperatures and pressures.

Other Niche Reactive Chemicals

A few other specific chemicals are listed in compatibility charts as having a severe effect on PTFE, though they are less common in industrial settings. These include diethylamine and gold monocyanide.

Understanding the Critical Role of Conditions

For a reaction to occur, it's not just about the chemical itself. The operating environment is often the deciding factor that enables a chemical attack.

The Impact of High Temperatures

As PTFE approaches its melting point (around 327°C or 621°F), its structural integrity weakens. This thermal energy can provide the activation energy needed for otherwise unlikely reactions to occur, making it more susceptible to attack by chemicals like reactive metals (aluminum, magnesium).

The Influence of High Pressure

High-pressure environments can force reactive molecules into closer and more prolonged contact with the PTFE structure. This increases the likelihood of a reaction with aggressive agents like fluorine gas.

"Good" vs. "Excellent": A Key Distinction

Not all chemical interaction results in catastrophic failure. It is important to distinguish between severe degradation and reduced performance.

When Compatibility Is Only "Good"

Some chemicals, such as chlorobenzene or high-aromatic gasoline, are rated as having "good" compatibility rather than "excellent." This typically means some minor physical effect, such as slight swelling or absorption, may occur over time.

The Vast Majority of Safe Chemicals

This does not change the fact that PTFE offers excellent, failure-proof resistance to the most common and aggressive chemicals used in industry. This includes nearly all concentrated and dilute acids, alkalis, alcohols, hydrocarbons, ketones, and industrial solvents.

Making the Right Choice for Your Application

- If your primary focus is general use with common acids, bases, or solvents: You can specify PTFE with an exceptionally high degree of confidence, as it is inert to these substances.

- If your application involves molten alkali metals or high-pressure fluorine gas: You must choose a different material. PTFE will fail in these specific, highly reactive environments.

- If you are operating at very high temperatures or with certain aromatic solvents: It is wise to verify compatibility, as you may experience minor swelling or a reduction in mechanical properties, even without catastrophic chemical failure.

Understanding these specific limitations is the key to leveraging PTFE's remarkable chemical resistance safely and effectively.

Summary Table:

| Chemical / Condition | Effect on PTFE | Severity |

|---|---|---|

| Molten Alkali Metals (e.g., Sodium) | Rapid decomposition | Severe |

| Elemental Fluorine (F₂) Gas | Chemical attack, especially under pressure | Severe |

| Potent Fluorinating Agents (e.g., ClF₃) | Degradation | Severe |

| High Temperatures (near 327°C / 621°F) | Increased susceptibility to attack | High Risk |

| High-Pressure Environments | Forces reactive contact | High Risk |

| Aromatic Solvents (e.g., Chlorobenzene) | Minor swelling (Good, not Excellent resistance) | Moderate |

Ensure Your Application's Safety with Precision-Engineered PTFE Components

While PTFE is remarkably inert, selecting the right material for extreme chemical environments is critical to preventing failure. KINTEK specializes in the custom fabrication of high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer expert guidance on material compatibility, from prototypes to high-volume orders. Don't risk component degradation; let our expertise ensure your system's integrity and longevity.

Contact our experts today to discuss your specific requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity