Yes, the specifications of PTFE bushings are highly customizable. Polytetrafluoroethylene (PTFE) is a material valued not just for its inherent properties like low friction and chemical resistance, but also for its exceptional machinability. This allows for the creation of bushings tailored to nearly any dimension, shape, or functional requirement your specific application demands.

The core takeaway is that PTFE should be viewed less as a standard, off-the-shelf component and more as a versatile base material. Its true potential is unlocked through customization, enabling engineers to design precise solutions for unique and challenging operational environments.

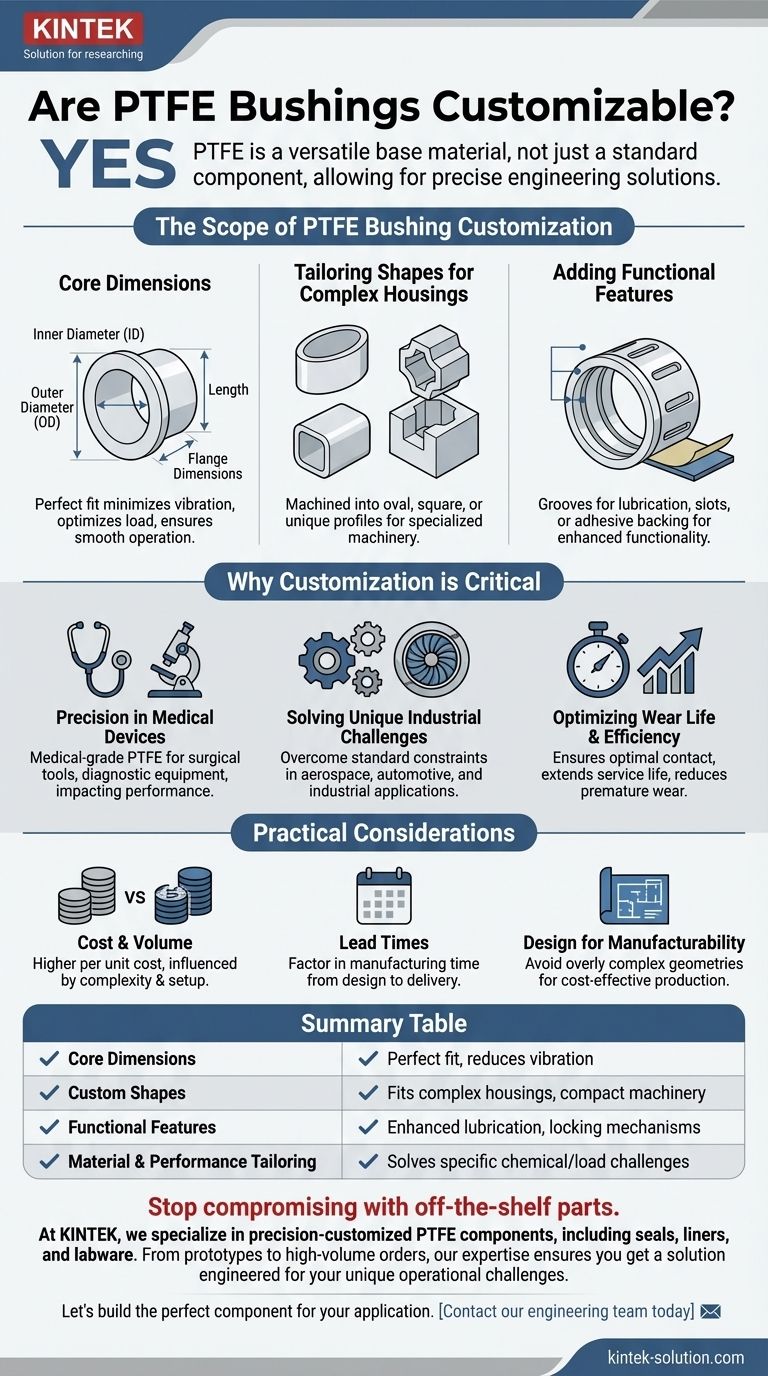

The Scope of PTFE Bushing Customization

While standard sizes are readily available, the real engineering advantage of PTFE lies in its adaptability. Customization goes far beyond simple length and diameter adjustments.

Customizing Core Dimensions

The most common form of customization involves tailoring the physical dimensions to exact specifications. This includes the inner diameter, outer diameter, length, and flange dimensions. Precise sizing ensures a perfect fit, which is critical for minimizing vibration, optimizing load distribution, and ensuring smooth operation.

Tailoring Shapes for Complex Housings

Many modern designs involve non-standard or irregularly shaped components where a simple cylindrical bushing will not fit. PTFE can be machined into custom shapes—oval, square, or entirely unique profiles—to match these complex housings perfectly. This capability is crucial for compact or specialized machinery.

Adding Functional Features

Customization can also involve adding features that enhance functionality. Bushings can be designed with grooves for lubrication distribution, slots for locking mechanisms, or even an adhesive backing for easier installation in certain applications, similar to how PTFE washers are customized.

Why Customization is Critical in Demanding Applications

Specifying a custom bushing is not merely about achieving a perfect fit; it's about solving a specific engineering problem and optimizing the performance of the entire assembly.

Precision in Medical and Scientific Devices

In applications like medical devices, precision is non-negotiable. Medical-grade PTFE can be customized in size, thickness, and configuration to meet stringent requirements for components in surgical tools or diagnostic equipment, directly impacting performance and patient outcomes.

Solving Unique Industrial Challenges

In industrial machinery, aerospace, or automotive applications, off-the-shelf components often represent a compromise. A custom PTFE bushing allows designers to overcome the constraints of standard parts, leading to more efficient, reliable, and innovative designs that perform under unique load, speed, or environmental conditions.

Optimizing Wear Life and Efficiency

A precisely-fit custom bushing ensures optimal contact and load distribution, which prevents premature and uneven wear. By matching the component's geometry and material properties to the specific application, you can significantly extend the service life of both the bushing and the mating parts.

Understanding the Practical Considerations

While the possibilities for customization are vast, it's important to approach the process with a clear understanding of the practical implications.

Cost and Volume

Custom manufacturing is inherently more expensive per unit than mass-produced standard parts, especially for small quantities. The cost is influenced by design complexity, material waste, and the setup time required for machining.

Lead Times

Standard bushings are typically in stock and available for immediate shipment. Custom-machined parts require a manufacturing lead time that must be factored into your project schedule, from initial design and quoting to final production and delivery.

Design for Manufacturability

While PTFE is highly machinable, there are still physical limitations. Overly complex geometries with extremely thin walls or intricate internal features can be challenging and costly to produce. Collaborating with your manufacturer during the design phase is crucial to ensure your concept is both functional and manufacturable.

How to Specify Your Custom PTFE Bushing

To ensure you get the right component, your request must be based on the core problem you are trying to solve.

- If your primary focus is fitting a non-standard housing: Provide the manufacturer with detailed CAD drawings, 3D models, or even a physical sample of the mating component.

- If your primary focus is meeting specific performance criteria: Clearly define the operational environment, including load, speed, temperature, and any chemical exposure, to ensure the correct dimensions and material grade are selected.

- If your primary focus is a simple one-off or prototype: Consider purchasing PTFE sheet or rod stock, which can often be easily trimmed or machined with basic tools to test a concept before committing to a full production run.

Ultimately, leveraging PTFE's customizability allows you to create a purpose-built component that perfectly solves your specific engineering challenge.

Summary Table:

| Customization Aspect | Key Benefit | Common Applications |

|---|---|---|

| Core Dimensions (ID, OD, Length) | Perfect fit, reduces vibration, optimizes load | General machinery, automotive |

| Custom Shapes (Oval, Square) | Fits complex, non-standard housings | Compact machinery, specialized equipment |

| Functional Features (Grooves, Slots) | Enhanced lubrication, locking mechanisms | High-performance industrial systems |

| Material & Performance Tailoring | Solves specific chemical, temperature, or load challenges | Medical devices, semiconductor, aerospace |

Stop compromising with off-the-shelf parts.

At KINTEK, we specialize in precision-customized PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a bushing that is not just a part, but a solution engineered for your unique operational challenges.

Let's build the perfect component for your application. Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications