It’s a scenario every analyst dreads. You’ve meticulously prepared your samples, your standards are perfect, and your multi-million dollar instrument is finely calibrated. You run the sequence, and the results come back… wrong. A phantom peak appears. Concentrations are inexplicably low. The baseline is noisy. Hours, or even days, of work are suddenly in question, all because of a ghost in the machine you can’t identify.

What do you do next? If you’re like most, you begin the frustrating and costly cycle of troubleshooting. You rerun the sample, prepare new standards, or waste valuable time recalibrating the instrument. But what if the problem isn’t your method, your solvent, or your machine? What if the culprit is a component so small and seemingly insignificant that it’s the last place you’d ever think to look?

The High Cost of a Failing Seal

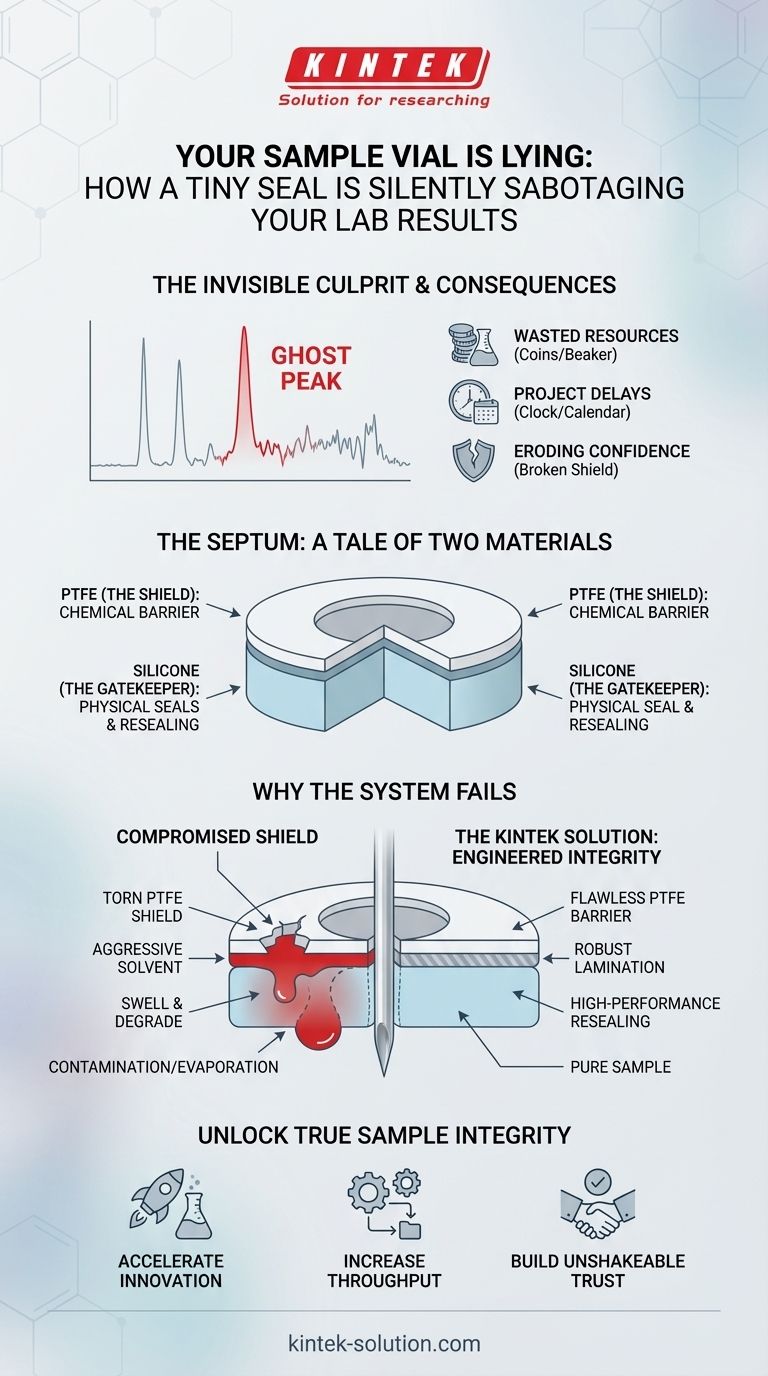

This issue of inconsistent data isn’t just an isolated incident; it's a chronic plague in analytical labs. The root cause is often misdiagnosed, leading to a cascade of negative business consequences:

- Wasted Resources: Every failed run consumes expensive solvents, rare samples, and costly chemical standards.

- Project Delays: Troubleshooting eats into timelines, pushing back R&D milestones and delaying time-to-market for new products.

- Eroding Confidence: Most importantly, unreliable data undermines the integrity of your lab’s work. When you can’t trust your results, critical decisions are made on shaky ground.

Many labs attempt to solve this by switching to cheaper vials or septa, believing them to be simple commodities. This only makes the problem worse. They are treating a symptom, not the underlying disease. The real problem lies in a fundamental misunderstanding of the materials science at play inside that tiny vial cap.

The Real Culprit: A Tale of Two Materials

The integrity of your sample depends on a microscopic battle being fought within the septum. This isn't about one single material; it's about a sophisticated partnership between two, each with a distinct and vital role.

The Shield: Polytetrafluoroethylene (PTFE)

Think of PTFE as the ultimate chemical bodyguard. It's an incredibly inert material that forms a thin, impenetrable barrier between your sample and the outside world. Its job is simple: to ensure absolutely nothing from the septum leaches into your sample and nothing from your aggressive solvent attacks the seal itself. It is the guarantee of chemical purity.

The Gatekeeper: Silicone

Behind the PTFE shield lies a thicker, more flexible layer of silicone. Silicone is a master of physical sealing. Its high elasticity allows it to form a tight seal around a piercing needle and, crucially, to reseal itself almost perfectly once the needle is withdrawn. Its job is to prevent sample evaporation and protect against atmospheric contamination.

Why the System Fails

Here is the critical truth: these two materials have opposing strengths. PTFE is a fantastic chemical barrier, but it’s rigid and doesn't reseal well. Silicone is a fantastic resealing material, but it has poor chemical resistance to many common organic solvents.

Failure occurs the moment this partnership is compromised. A blunt needle or a poorly designed septum can tear or puncture the thin PTFE shield. Once breached, your aggressive solvent bypasses the shield and comes into direct contact with the vulnerable silicone core. The silicone swells, degrades, and fails. The seal is broken. Your sample is now compromised by contamination, evaporation, or both.

This is why your troubleshooting efforts fail. You’re looking for a complex problem when the reality is a simple mechanical failure at a microscopic level.

The Solution: A Seal Engineered from First Principles

To permanently solve this problem, you don't just need a septum; you need a septum that is engineered with a deep understanding of this material science conflict. You need a component where the inert PTFE shield and the elastic silicone core work in perfect harmony, injection after injection.

This is precisely where KINTEK’s expertise in precision PTFE manufacturing becomes critical. We don’t just bond two materials together; we create an integrated sealing system.

- Flawless PTFE Barrier: Our manufacturing process ensures a uniform, pinhole-free PTFE layer that provides the ultimate chemical inertness, protecting your sample from any potential leaching.

- Robust Lamination: The bond between our PTFE and silicone layers is designed to withstand repeated punctures without delaminating or tearing, preserving the integrity of the chemical shield.

- High-Performance Resealing: We use high-purity, resilient silicone that guarantees excellent resealability, securing your sample against evaporation and protecting it between injections.

Our PTFE/Silicone septa are not just a product; they are the physical embodiment of the solution to the root cause of data inconsistency. They are designed to ensure the PTFE shield never fails, so the silicone gatekeeper can always do its job.

Beyond Reliable Data: What True Sample Integrity Unlocks

When you eliminate this chronic source of error, you do more than just get better data. You transform what’s possible in your lab.

- Accelerate Innovation: You can confidently work with more aggressive solvents and trace-level analytes, pushing the boundaries of your research without fear of contamination.

- Increase Throughput: By eliminating the need for constant reruns, your team can process more samples in less time, drastically improving lab efficiency and reducing project costs.

- Build Unshakeable Trust: You can stand behind every single data point, knowing your results are a true reflection of your sample, not a byproduct of a failing seal. This allows for faster, more confident decision-making, from R&D discovery to final product quality control.

Stop chasing ghosts in your baseline and start building your analytics on a foundation of absolute certainty. The integrity of your most critical work depends on the quality of your smallest components. If you're ready to move past troubleshooting and focus on discovery, our team of material science experts is here to help you specify the right solution for your unique application. Contact Our Experts.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

Related Articles

- The Unbreakable Bond: Why PTFE Defines Chemical Containment and Purity

- The Specialist's Dilemma: Understanding the Critical Trade-offs of PTFE-Lined Valves

- Your Plant's Silent Killer: Why Standard Valves Fail with Corrosive Chemicals (And the One Fix That Works)

- Why Your Lab Plugs Stick and Contaminate: The Hidden Science of Surface Energy

- The Precision Trap: Understanding the Hidden Trade-offs of PTFE-Lined Globe Valves