You know the feeling. A critical process is complete, and it’s time to remove a plug from a valuable piece of equipment—a glass reactor, a stainless steel manifold, a sensitive analytical instrument. You apply gentle pressure. Nothing. You twist a little harder. Still stuck. You reach for a tool, your breath held, knowing that one slip could mean a costly scratch, a broken port, or worse, a compromised seal that has already ruined the batch.

That moment of frustration, where a simple component holds an entire operation hostage, is more than just an annoyance. It's a symptom of a fundamental misunderstanding of what makes a seal truly effective.

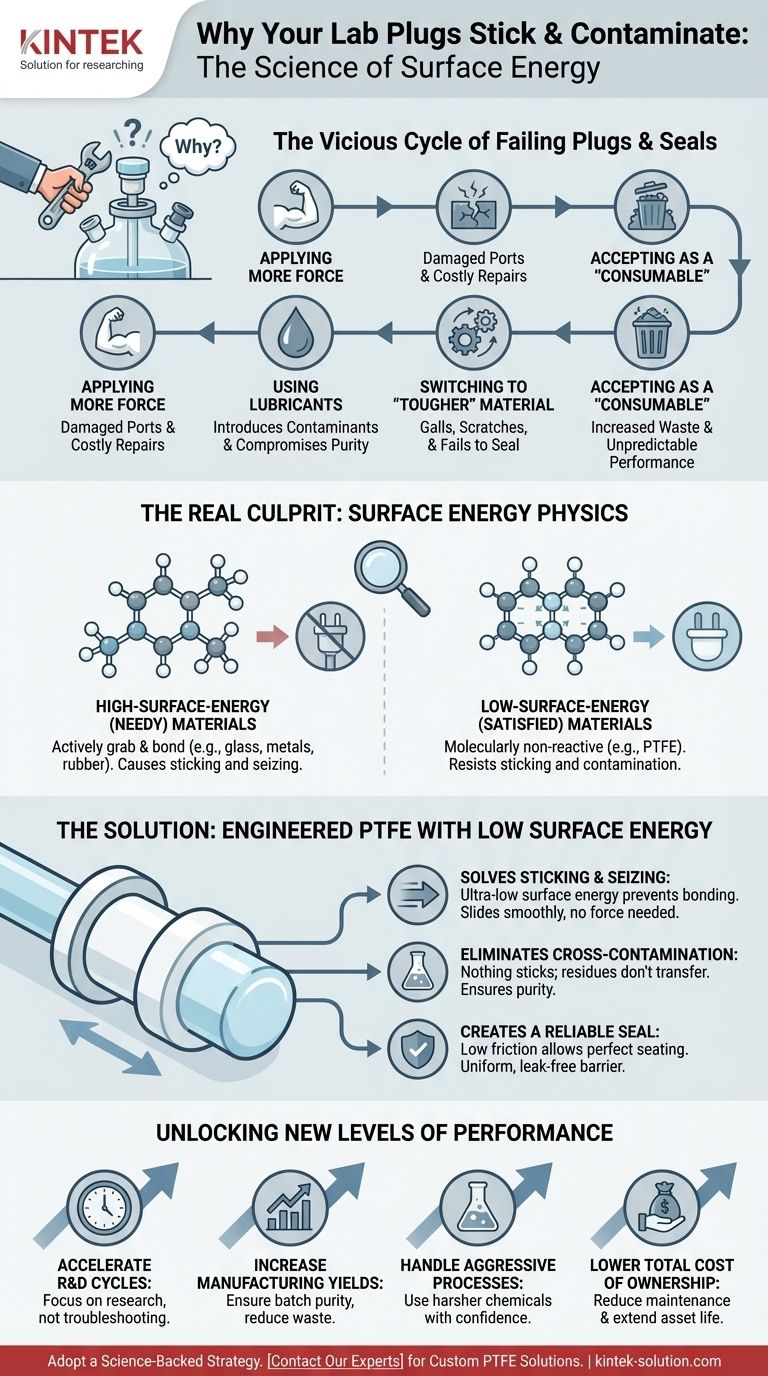

The Vicious Cycle of Failing Plugs and Seals

If this scenario sounds familiar, you're not alone. Across labs, chemical plants, and high-purity manufacturing, teams are caught in a frustrating loop of troubleshooting their sealing components. The common "fixes" often look like this:

- Applying More Force: Trying to muscle a stuck plug out, which often ends in damaged equipment and costly repairs or replacements.

- Using Lubricants: Applying grease or silicone sprays seems like a quick fix, but it introduces a new contaminant into your otherwise pure system, compromising results and batch integrity.

- Switching to a "Tougher" Material: Moving to a harder elastomer or even a metal plug, only to find it galls, scratches the port, or fails to create a truly leak-proof seal.

- Accepting It as a "Consumable" Problem: Treating plugs as single-use items, leading to constant reordering, increased waste, and unpredictable performance.

These aren't just operational headaches; they have direct business consequences. A single contaminated batch in a pharmaceutical process can cost hundreds of thousands of dollars. Downtime for replacing a damaged port on a semiconductor processing tool can halt production for days. In the lab, chasing phantom contamination from faulty seals wastes valuable research hours and delays breakthroughs. We keep treating the symptoms, but the problem keeps coming back.

The Real Culprit: It's Not Material Strength, It's Surface Physics

Here is the turning point: The problem isn’t that your plugs aren't strong enough or tight enough. The root cause is a principle called "surface energy."

Think of surface energy as microscopic stickiness.

- High-Surface-Energy Materials: Most materials, including glass, metals, and common plastics or rubbers, have high surface energy. At a molecular level, they are "needy"—they actively want to grab onto and bond with other surfaces. This is what causes a rubber stopper to feel "glued" in place or a plastic plug to seize after exposure to chemicals.

- Low-Surface-Energy Materials: A few materials, however, are fundamentally different. Their surfaces are molecularly "satisfied" and non-reactive. They have very little desire to stick to anything else.

The common "solutions" fail because they ignore this fundamental principle. Applying force just tries to brutishly overcome the molecular adhesion. Lubricants add a temporary barrier but contaminate the system. Switching to another high-surface-energy material just trades one form of sticking for another. You're fighting physics, and it's a battle you will consistently lose.

The Right Tool for the Job: Engineering Around Surface Energy

To permanently solve a problem rooted in surface physics, you need a solution designed with that physics in mind. You need a material with inherently low surface energy, combined with the precision to make that property count.

This is precisely where Polytetrafluoroethylene (PTFE) excels. Its legendary non-stick property isn't a coating; it's a fundamental characteristic of its molecular structure. PTFE has one of the lowest surface energies of any solid material.

At KINTEK, we don't just sell PTFE; we engineer solutions based on a deep understanding of these principles. Our precision-machined PTFE plugs, seals, and liners are the physical embodiment of the right solution.

- It Solves Sticking and Seizing: Because of its ultra-low surface energy, a KINTEK PTFE plug will not bond to the port surface. It slides in and out smoothly, every time, even after prolonged exposure to aggressive chemicals or high temperatures. No force, no damage.

- It Eliminates Cross-Contamination: Since nothing sticks to the PTFE surface, residues from one process are not carried into the next. The plug comes out clean, ensuring the purity of your product or the integrity of your experiment.

- It Creates a More Reliable Seal: The material's low friction allows it to seat perfectly against the sealing surface without catching or galling, creating a uniform, dependable, and leak-free barrier. Our precision manufacturing guarantees the fit is perfect, allowing the material's properties to perform flawlessly.

Beyond the Fix: Unlocking New Levels of Performance

When you stop fighting with basic components, you unlock the potential to push your operations to a new level. What was once a source of chronic problems becomes a cornerstone of reliability.

With a properly designed PTFE sealing solution, you can now:

- Accelerate R&D Cycles: Stop wasting time troubleshooting contamination or worrying about equipment seizure. Focus on the actual research.

- Increase Manufacturing Yields: Ensure batch-to-batch purity in semiconductor, medical, and pharmaceutical production, reducing waste and improving quality.

- Handle More Aggressive Processes: Use harsher chemicals or higher temperatures with confidence, knowing your seals won't degrade, react, or fail.

- Lower Total Cost of Ownership: Drastically reduce maintenance downtime, eliminate the cost of damaged equipment, and extend the operational life of your most valuable assets.

Solving this persistent issue isn't about finding a better plug; it's about adopting a better, science-backed strategy. By addressing the root cause of failure, you transform a point of weakness into a source of strength, enabling greater efficiency, purity, and innovation across your entire operation.

If you're ready to move beyond the cycle of temporary fixes and implement a permanent solution for your sealing and fluid handling challenges, our team is here to help. We specialize in translating your unique operational needs into precision-engineered components that deliver unmatched reliability. To explore how custom PTFE solutions can enhance your specific project, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

Related Articles

- The Unseen Component: How PTFE Became the Bedrock of Medical Device Reliability

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions