It’s 3 a.m. and an alarm is blaring. A pressure sensor on a critical chemical processing line has tripped, and production is grinding to a halt. When you arrive, you find the same old story: another seized valve, a potential leak of hazardous material, and an entire batch of product at risk of contamination. You thought the last "upgraded" valve would fix this. It didn't.

This isn't a freak accident; for many process engineers and plant managers, it's a recurring nightmare.

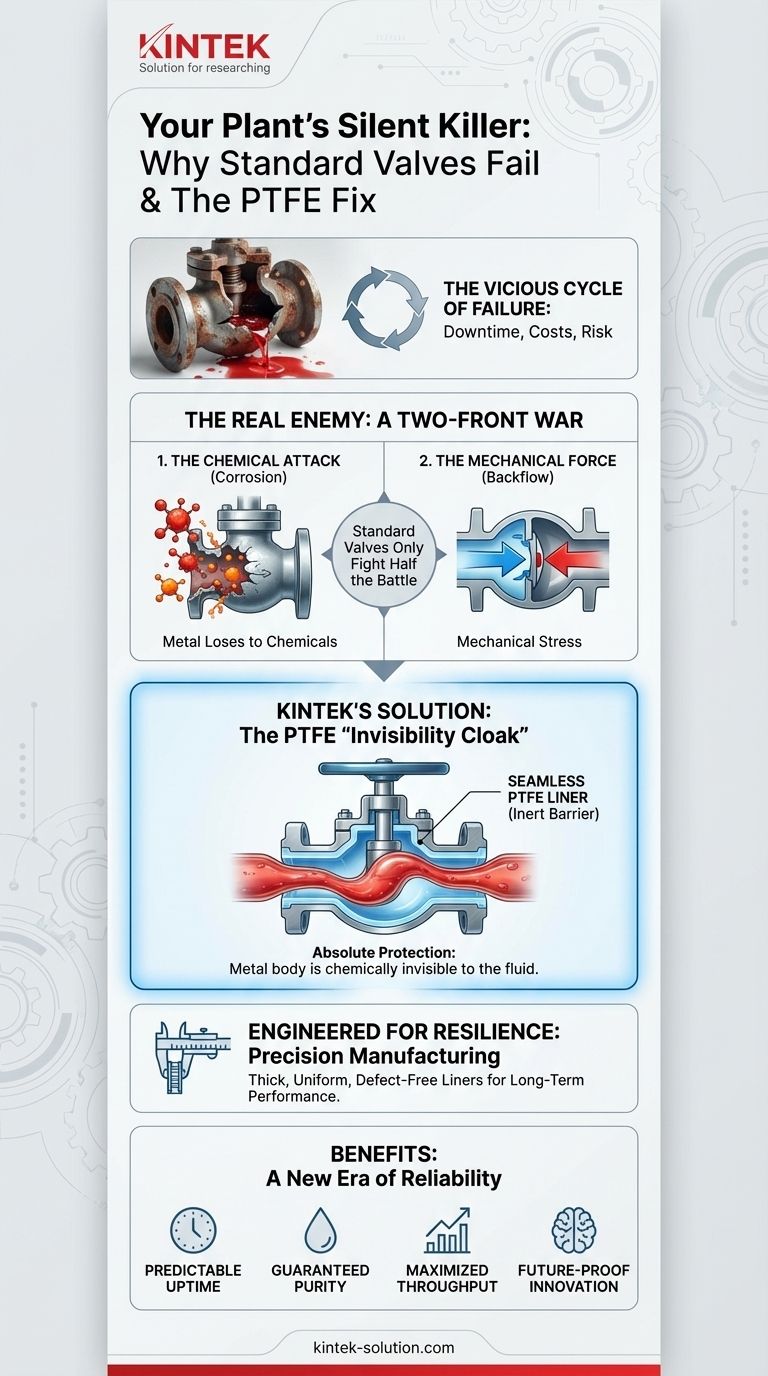

The Vicious Cycle: Why "Stronger" Valves Keep Failing

If you manage systems that handle aggressive fluids—strong acids, alkalis, solvents, or high-purity chemicals—you've likely experienced this frustrating cycle. A valve fails, you replace it, and weeks or months later, the replacement fails, too.

In the search for a solution, many well-meaning teams fall into the same traps:

- Upgrading the Metal: You switch from standard steel to a more expensive stainless steel or even a high-nickel alloy. It lasts a bit longer, but eventually, corrosion wins.

- Increasing Maintenance: You implement more frequent inspections and preventative replacements. This becomes a costly, labor-intensive band-aid that doesn't solve the underlying issue.

- De-rating the Process: You try to "baby" the valve by operating at lower temperatures or pressures, sacrificing your plant's efficiency and throughput.

These efforts, while logical, only address the symptoms. The business consequences of not finding a real cure are severe: unplanned downtime destroys production schedules, frequent valve replacements drain maintenance budgets, contaminated batches lead to wasted materials, and the constant risk of a chemical leak poses a significant safety and environmental liability.

The Real Enemy: It’s Not Just a Mechanical Problem

The cycle of failure continues because most attempts focus on the wrong problem. The issue isn't simply that the valve isn't "strong enough." The truth is you are fighting a war on two fronts, and most valves are only designed to fight on one.

Fighting a Two-Front War: Corrosion and Backflow

Every chemical line faces two distinct threats:

- The Chemical Attack (Corrosion): Aggressive fluids are relentlessly trying to eat away at the valve's internal metal components. No matter how "strong" the alloy, it's a chemical battle that metal will eventually lose.

- The Mechanical Force (Backflow): If flow reverses, it can contaminate upstream processes, create dangerous chemical reactions, and damage expensive equipment like pumps and sensors. A check valve's job is to mechanically prevent this.

This is the core of the problem: a standard check valve can handle the mechanical force of backflow, but its metal body is defenseless against the chemical attack. You are using a tool designed for a mechanical problem to fight a chemical war. This is why the "stronger" valve strategy is doomed to fail—it's like putting thicker armor on a soldier who is being poisoned.

The Invisibility Cloak: Solving the Problem with Material Science

To win this two-front war, you don't need a stronger metal. You need to make the valve's metal body chemically invisible to the fluid it's controlling.

The solution lies in creating a perfect, impenetrable barrier between the corrosive chemical and the valve's structural components. This requires a material that is not just resistant, but almost completely inert.

This is the role of PTFE (Polytetrafluoroethylene). By lining every wetted surface of the valve with a seamless layer of precision-formed PTFE, you create a chemical "invisibility cloak." The corrosive fluid flows through, touching only the inert liner, completely unaware of the metal structure just millimeters away. The valve's body provides the mechanical strength to control flow and pressure, while the PTFE liner provides absolute protection from chemical attack.

KINTEK: Engineering the Perfect Shield

This isn't just about splashing a layer of coating on a part. A faulty or improperly formed liner—one with pinholes, thin spots, or poor adhesion—is worse than no liner at all, as it can trap corrosives and accelerate failure.

This is where KINTEK's expertise in precision manufacturing becomes critical. We specialize in fabricating custom PTFE components, including the robust liners and seals that are the heart of a high-performance chemical valve. Our process is born from a deep understanding of this exact failure mode. We engineer each component to provide a thick, seamless, and perfectly uniform barrier that is physically and chemically resilient. Our liners aren't just parts; they are the purpose-built solution to the two-front war, ensuring the valve's metal body is never exposed to your process fluid.

From Fighting Fires to Fueling Growth: A New Era of Reliability

When you solve this recurring problem at its root, you do more than just stop replacing valves. You fundamentally change what's possible for your operations.

- Predictable Uptime: Instead of reacting to costly unplanned shutdowns, you can plan for long-term, reliable service, maximizing plant profitability.

- Guaranteed Purity: You can confidently protect your processes from backflow and contamination, ensuring product quality and protecting your brand's reputation.

- Maximized Throughput: With equipment you can trust, you can run your processes at their optimal temperatures and pressures, increasing efficiency without fear of premature failure.

- Future-Proof Innovation: You can now confidently explore the use of more aggressive chemicals or develop new processes that were previously considered too risky, opening doors to innovation and giving you a competitive edge.

The principles that make a lined valve successful apply to every component in your fluid path, from seals and gaskets to pipes and vessels. The right material science doesn't just repair a system; it makes it resilient. If you're ready to break the cycle of "replace and fail," our team of material and fabrication experts is here to help you design a system that lasts. To discuss your unique project and eliminate these recurring failures for good, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good