You specified a top-of-the-line, spring-energized PTFE seal. It was supposed to be the final solution for that critical, high-pressure line—the one component you wouldn't have to worry about. Yet, here you are, staring at another failed test, another leak. The pressure drops, the system shuts down, and the project timeline slips. You did everything right, so why does the “best” seal on the market keep letting you down?

This isn't a rare mishap; it's a frustratingly common story for engineers in demanding fields like semiconductor, medical, and aerospace.

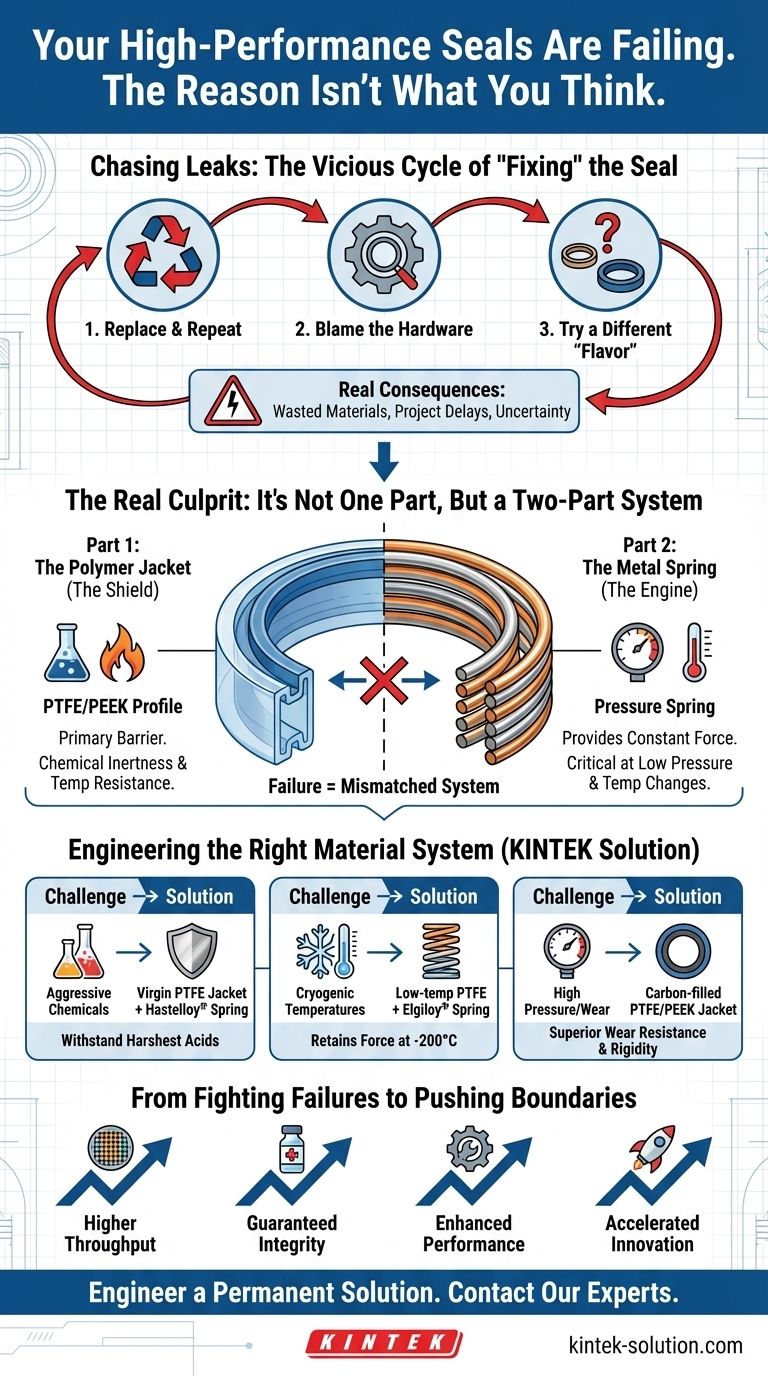

Chasing Leaks: The Vicious Cycle of "Fixing" the Seal

When a critical seal fails, the reaction is almost automatic. You might find yourself in a familiar loop:

- Replace and Repeat: You order a direct replacement, assuming the first one was a fluke. It works for a while, then fails in the exact same way.

- Blame the Hardware: You start questioning the hardware. "Is the groove machined incorrectly? Is the surface finish not right?" This leads to costly and time-consuming remachining, often with no improvement.

- Try a Different "Flavor": You switch to another brand of spring-energized seal, or one with a slightly different profile, hoping for a different outcome. The problem persists.

This cycle does more than just cause headaches. It has real business consequences. A single leak can ruin a multi-thousand-dollar batch of semiconductor wafers, contaminate a priceless biological sample, or ground an expensive piece of industrial equipment. The costs add up quickly: wasted materials, project delays, endless troubleshooting hours, and a growing uncertainty in your product's reliability.

The core issue is that these "solutions" are just shots in the dark. They fail because they don't address the real reason the seal is leaking.

The Real Culprit: It's Not One Part, But a Two-Part System

The fundamental mistake is thinking of a spring-energized seal as a single component. It is not. It is a precision-engineered two-part system, and failure occurs when these two parts are not perfectly matched to your specific environment.

Let's break it down.

Part 1: The Polymer Jacket (The Shield)

This is the main body of the seal, typically made from PTFE (Teflon) or other advanced polymers like PEEK. Its job is to be the primary barrier. It provides the incredible chemical inertness and wide temperature resistance that made you choose it in the first place. It’s the shield that stands up to corrosive chemicals and extreme temperatures.

Part 2: The Metal Spring (The Engine)

Tucked inside the jacket is a metal spring. This is the engine of the seal. Its job is to provide a constant, live mechanical force, pushing the lips of the jacket outwards to create a tight seal.

This is the part everyone overlooks. The spring is critical in two situations:

- At low pressure: It ensures a tight seal before system pressure kicks in.

- During temperature changes: It compensates for the jacket's behavior. For example, in cryogenic applications, a PTFE jacket will shrink. Without the right spring constantly pushing it outward, a gap will open, and a leak is guaranteed.

The "common solutions" from the previous section fail because they ignore this system. A seal with a standard stainless steel spring will inevitably fail in a cryogenic fluid line, because the spring loses its "springiness" at low temperatures. A virgin PTFE jacket might be destroyed in a high-pressure, abrasive environment where a carbon-filled PTFE jacket was needed.

You weren't choosing the wrong type of seal; you were using a mismatched system of materials.

Beyond Parts: Engineering the Right Material System

To permanently solve the problem, you need to stop buying a part and start specifying a system. This requires a partner who understands the intricate relationship between the jacket polymer and the spring alloy.

This is precisely why KINTEK focuses on precision fabrication based on application-specific material science. We don't just sell seals; we engineer solutions based on a deep understanding of why they fail.

- Facing Aggressive Chemicals? The problem is likely corrosion of the spring or degradation of the jacket. The solution isn't just any PTFE seal, but a virgin PTFE jacket for purity, paired with a Hastelloy® spring that can withstand the harshest acids.

- Leaking at Cryogenic Temperatures? The root cause is the spring losing its force and the jacket shrinking. We solve this by specifying an Elgiloy® spring, which retains its mechanical energy even at -200°C, combined with a specific grade of PTFE jacket engineered for low-temperature performance.

- Seal Wearing Out Under High Pressure? A standard jacket material is likely deforming or "creeping" under load. The right approach is to use a more robust jacket material, like carbon-filled PTFE or PEEK, which offers superior wear resistance and rigidity.

Our expertise isn't just in making PTFE components. It’s in diagnosing your challenge and fabricating the exact combination of jacket and spring that creates a reliable system for your unique pressure, temperature, and media.

From Fighting Failures to Pushing Boundaries

When you no longer have to worry about seal reliability, your focus can shift from troubleshooting to innovation. What new possibilities open up when your components are fundamentally dependable?

- Higher Throughput: Semiconductor fabs can run longer, more stable processes without unplanned maintenance, directly increasing wafer yield.

- Guaranteed Integrity: Laboratories and medical device makers can trust that sensitive media will remain pure, eliminating the risk of contaminated batches or inaccurate results.

- Enhanced Performance: Industrial engineers can design equipment that operates at higher pressures or more extreme temperatures, creating products that are more powerful and durable than the competition.

- Accelerated Innovation: R&D teams can move faster, knowing their test hardware is robust. You can focus on pushing the science forward, not fixing leaks.

Solving a recurring seal failure isn't just about fixing a leak. It's about unlocking your system's true potential. The right seal is more than a part number; it’s a conversation about your specific challenge, and it starts with understanding the science of how it works.

If you're tired of chasing leaks and are ready to engineer a permanent solution, our team is here to help you specify the right material system for your project. Let's discuss the unique pressures, temperatures, and materials in your application. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault