It’s a scenario that plays out far too often in high-stakes environments. A critical pump, handling aggressive or high-purity chemicals, suddenly fails. An alarm sounds. Production halts. A hazardous, expensive fluid begins to leak. The diagnosis is always the same: another failed mechanical seal.

You’re left with costly downtime, wasted product, and a potential safety hazard. The most frustrating part? This probably isn’t the first time it’s happened.

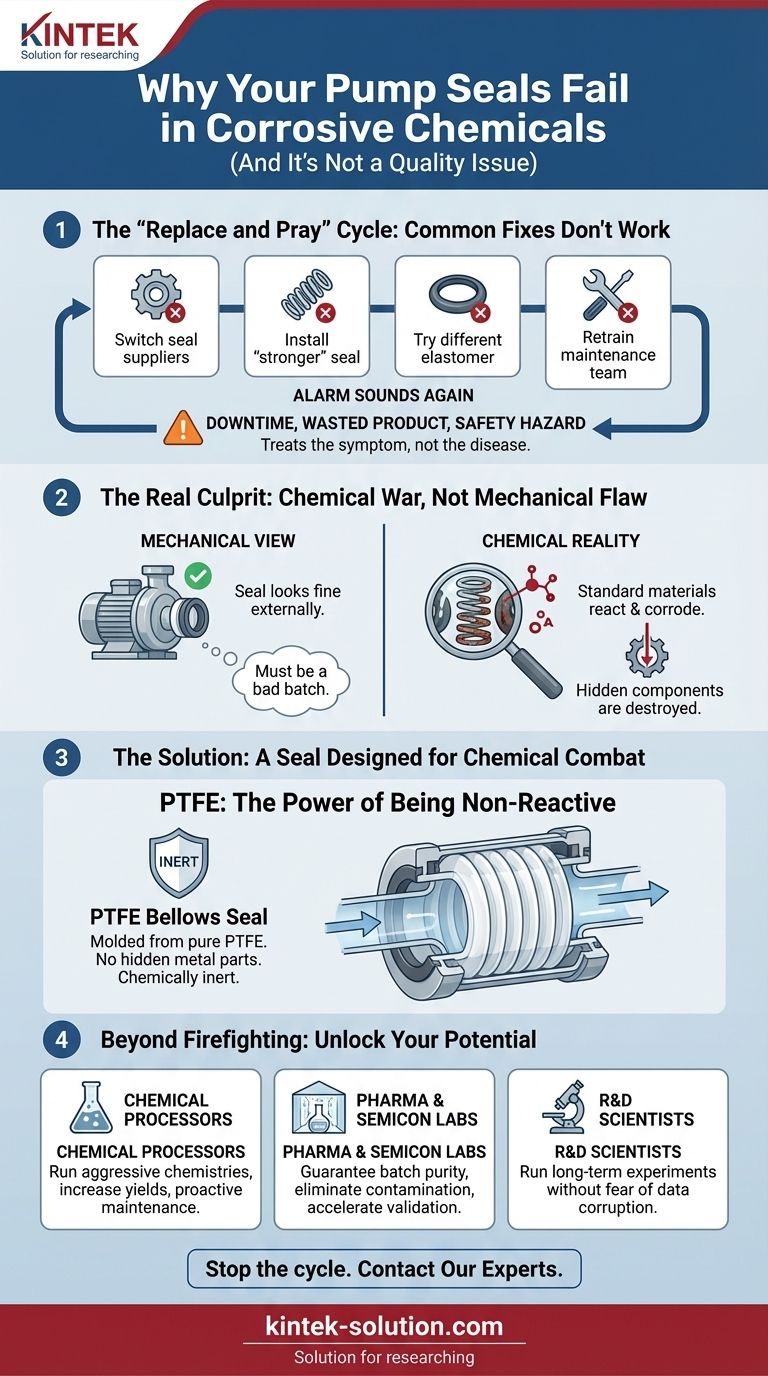

The "Replace and Pray" Cycle: Why Common Fixes Don't Work

For many plant managers and process engineers, this triggers a familiar, frustrating cycle. You investigate the failure and try what seems like a logical fix.

Perhaps you:

- Switch seal suppliers, assuming the last one was a "bad batch."

- Install a "stronger" seal with metal springs, believing it will be more durable.

- Try a different type of elastomer (rubber), hoping it will hold up better.

- Retrain the maintenance team on installation procedures, suspecting human error.

And for a short time, things might seem fine. But soon enough—whether weeks or months—the alarm sounds again. The seal has failed.

This isn't just an inconvenience; it's a significant business problem. Each failure means unplanned downtime, missed production targets, and direct costs from lost product and cleanup. In pharmaceutical or semiconductor applications, a single seal failure can contaminate an entire multi-million dollar batch, setting back timelines and profits.

If you’re stuck in this loop, it’s because these "solutions" all share the same mistake: they treat a symptom, not the disease.

The Real Culprit: It's a Chemical War, Not a Mechanical Flaw

Here is the fundamental truth that is often missed: Your seal isn't just failing mechanically; it's being destroyed chemically.

When you're pumping strong acids, solvents, or other corrosive media, you are asking your equipment to contain a relentless attacker. Most standard seal materials, like elastomers and many metals, are chemically reactive.

- Elastomers (Rubber Seals): When exposed to aggressive chemicals, the molecular bonds in the rubber are broken down. The seal may swell, become brittle, or simply dissolve over time. Switching from one elastomer to another is like offering the attacker a different meal—the end result is the same.

- Seals with Metal Springs: This is an even more insidious failure. The seal may look fine on the outside, but the process fluid inevitably finds its way to the internal metal spring. This hidden component, which provides the critical force to keep the seal faces closed, begins to corrode. Once it weakens or breaks, the seal experiences a sudden, catastrophic failure.

The common fixes fail because they try to solve a chemical problem with a purely mechanical mindset. You can't win a chemical war with a material that corrodes. You need a material that refuses to fight back.

The Power of Being Non-Reactive

The solution lies in using a material that is almost completely chemically inert. Enter Polytetrafluoroethylene (PTFE).

PTFE is a fluoropolymer that is non-reactive to nearly all industrial chemicals and solvents. It doesn't corrode, dissolve, or degrade. It simply endures. By choosing PTFE, you are removing the chemical reaction from the equation entirely.

But just choosing the right material is only half the battle. It must be used in the right design.

The Solution: A Seal Designed for Chemical Combat

If the root cause is a chemical attack on vulnerable materials (especially hidden ones like springs), then the ideal solution must do two things:

- Use a completely inert material for all wetted parts.

- Eliminate hidden, vulnerable components like metal springs from the fluid path.

This is precisely the principle behind the PTFE Bellows Seal.

This isn't just a seal made from PTFE; it's a seal designed around PTFE. The clever bellows construction is molded from a single piece of pure PTFE. This bellows acts as both the flexible barrier and the spring, providing the closing force needed for a tight seal without any metal parts.

It is a design of elegant simplicity. There are no elastomer O-rings to dissolve and no hidden metal springs to corrode. The only material your aggressive chemical ever touches is pure, inert PTFE.

This is how you break the "replace and pray" cycle. You aren't just installing a component; you are deploying a purpose-built solution that is fundamentally immune to the problem that caused all the previous failures. At KINTEK, we specialize in the precision fabrication of these PTFE components, ensuring that the design integrity matches the material's inherent strength, preventing issues like creep and guaranteeing a long, reliable service life.

Beyond Firefighting: What's Possible with Unbreakable Confidence?

When you stop worrying about the next seal failure, a remarkable shift happens. Your focus moves from reactive crisis management to proactive innovation and optimization.

What does this new reality look like?

- For Chemical Processors: You can run more aggressive chemistries that were previously too risky, increasing yields or creating new products. You can schedule maintenance on your terms, not on the terms of an emergency failure.

- For Pharmaceutical and Semiconductor Labs: You can guarantee batch purity with absolute confidence. By eliminating a primary source of metallic and elastomeric contamination, you improve product quality, increase yields, and accelerate validation processes.

- For R&D Scientists: You can run long-term experiments without the fear that an equipment failure will corrupt your data, allowing you to push the boundaries of discovery faster.

Solving this persistent sealing problem isn't just about improving uptime. It's about unlocking the full potential of your processes, your products, and your people. If you’re ready to move beyond temporary fixes and implement a permanent solution, our team is here to help you design the precise component for your unique challenge. Let's discuss how to end the cycle of failure for good. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority