You did everything by the book. To handle the aggressive chemicals in your piping system, you specified and installed what you were told was the best: a high-performance PTFE expansion joint. For a while, it worked perfectly.

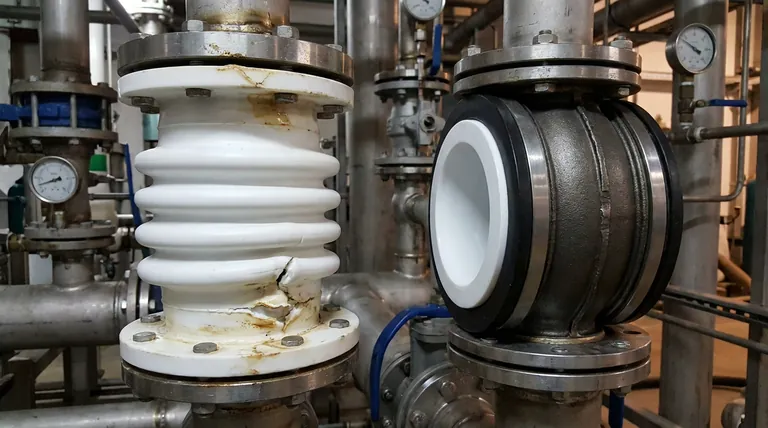

Then comes the alert. A pressure drop. A visual inspection confirms your fear: a leak, right at the "solution" you put in place. Now you’re facing an unplanned shutdown, a potential safety hazard, and a frustrating puzzle. You chose the right material—PTFE is universally chemical-resistant. So why did it fail?

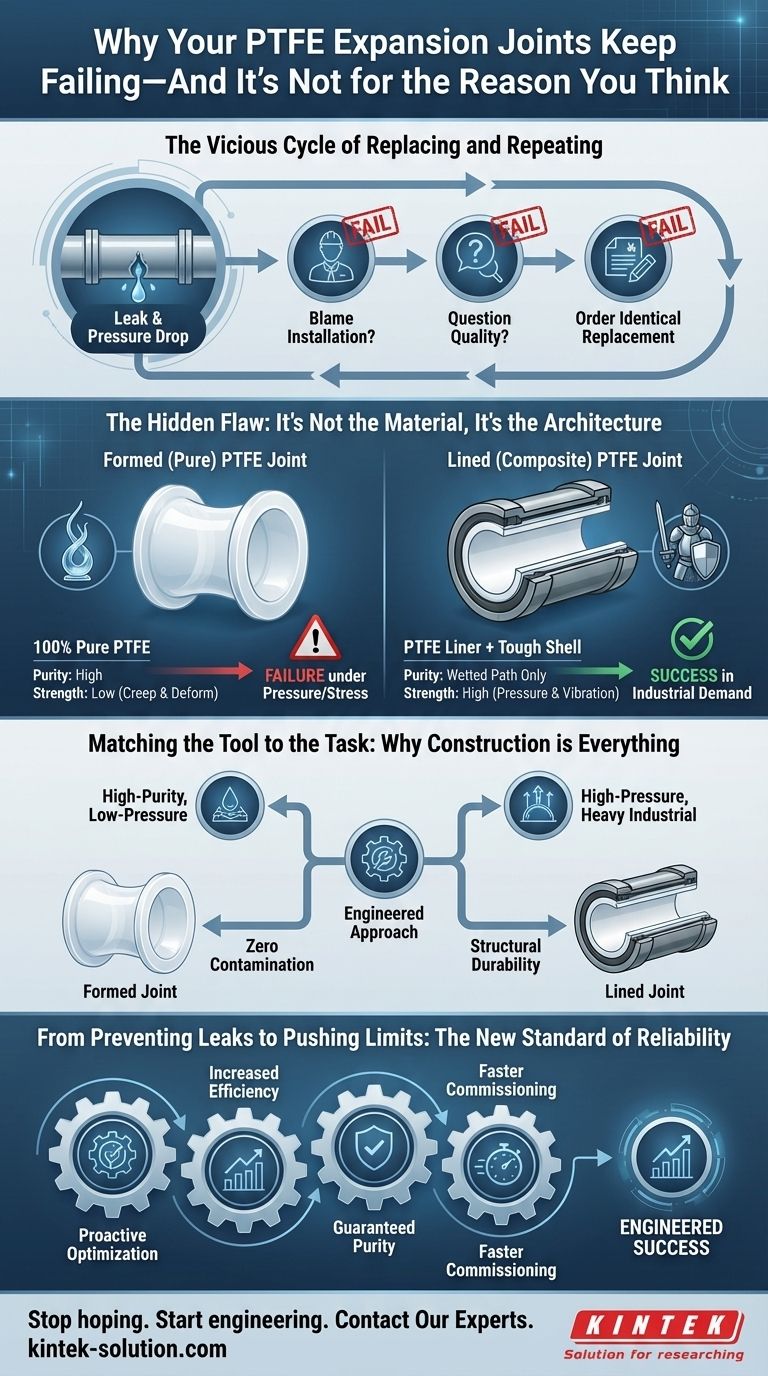

The Vicious Cycle of Replacing and Repeating

If this scenario sounds familiar, you're not alone. Across chemical plants, pharmaceutical labs, and semiconductor fabs, engineers face this exact problem. It triggers a costly and frustrating cycle of troubleshooting that rarely addresses the real issue.

The immediate response is often to:

- Blame the installation: "Did we over-torque the bolts?"

- Question the quality: "Was this a bad batch of PTFE?"

- Order an identical replacement: "It must have been a fluke. Let's install a new one, exactly the same."

Each of these steps treats the symptom—the failed joint—not the underlying disease. Meanwhile, the consequences mount. Unplanned downtime can cost thousands of dollars per hour. A single leak can contaminate an entire high-purity product batch, forcing you to scrap it. Most importantly, it creates a persistent, low-level anxiety: you can no longer trust a critical component of your system.

This cycle of failure and replacement continues because the initial diagnosis is wrong. The problem is almost never the material itself. It’s something far more fundamental.

The Hidden Flaw: It’s Not the Material, It’s the Architecture

The assumption that "PTFE is PTFE" is the root of the problem. While the material offers unmatched chemical resistance, its effectiveness depends entirely on its construction. There are two fundamentally different architectures for PTFE expansion joints, and choosing the wrong one for your application is like sending a world-class sprinter to compete in a weightlifting competition. Failure is inevitable.

Architecture 1: The Formed (Pure) PTFE Joint

Think of this as a pure glass sculpture. It is molded entirely from 100% pure PTFE.

- Its Strength: Unbeatable purity. Since nothing touches your media except virgin PTFE, it's the perfect choice for systems where even the slightest contamination is unacceptable, like in pharmaceutical or semiconductor manufacturing.

- Its Weakness: It's structurally delicate. Like that glass sculpture, it has low tolerance for physical stress—specifically, high pressure, system vibration, or mechanical shock.

When you put a pure, formed joint into a high-pressure industrial chemical line, the constant force causes the material to slowly stretch, deform, and "creep" until it ultimately fails.

Architecture 2: The Lined (Composite) PTFE Joint

Think of this as a knight in shining armor. It consists of a thin, pure PTFE liner on the inside, protected by a robust outer shell made of rubber or metal.

- Its Strength: It combines the best of both worlds. You get the universal chemical immunity of the PTFE liner on the inside, plus the immense mechanical strength and pressure resistance of the outer armor.

- Its Weakness: The outer shell materials may not be suitable for ultra-high-purity applications where wetted-path purity is the absolute priority.

This is the workhorse for demanding industrial environments like power generation or heavy chemical plants, where pressure and vibration are constant challenges.

The common troubleshooting steps fail because replacing a fragile "glass sculpture" with another one in a high-stress environment will always lead to the same result. You're solving the wrong problem.

Matching the Tool to the Task: Why Construction is Everything

The permanent solution is not to find "better PTFE." It is to ensure the architecture of the joint perfectly matches the demands of your system. You need a tool designed for the specific task at hand.

This means moving beyond off-the-shelf solutions and embracing an engineered approach. To guarantee reliability, you need a component designed with a deep understanding of its application.

This is precisely where KINTEK’s expertise lies. We don’t just manufacture PTFE components; we engineer solutions based on a first-principles diagnosis of your system's needs.

- For your high-purity, low-pressure pharmaceutical line: We deliver precision-molded formed (pure) PTFE expansion joints, ensuring zero contamination and absolute product integrity.

- For your high-pressure, heavy industrial chemical system: We fabricate robust lined (composite) PTFE expansion joints, providing the structural durability to withstand years of vibration and pressure without compromising chemical resistance.

Because we specialize in custom fabrication from prototype to high-volume production, we don’t force a one-size-fits-all product into your critical system. We build the exact component your application demands, eliminating the architectural mismatch that causes chronic failures.

From Preventing Leaks to Pushing Limits: The New Standard of Reliability

When you solve the chronic failure problem at its source, you do more than just stop leaks. You unlock new potential for your entire operation.

Instead of reactively managing downtime, your team can focus on proactive optimization. You can confidently increase operating pressures or temperatures to improve process efficiency. You can guarantee the consistency and purity of every batch, reducing waste and improving your bottom line. Commissioning new lines becomes faster and more predictable because you can specify the correct, failure-proof component from day one.

You move from a state of hoping parts don't fail to engineering a system that you know will succeed. This is the new standard of reliability.

The key is to stop treating expansion joints as commodities and start treating them as critical, engineered components. A conversation about your specific operating conditions—pressure, temperature, media, and purity goals—is the first step toward building a truly resilient system. Let our team help you diagnose your challenge and engineer the permanent solution. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

Related Articles

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work