It’s a scenario every analytical chemist dreads. You run a critical HPLC analysis on a high-value sample, and an unexpected 'ghost peak' appears in your chromatogram. Or perhaps the results from today’s batch are wildly different from yesterday’s, even though you followed the exact same procedure. The data is compromised, and you have no idea why.

You’re not alone in this frustration. This phantom problem plagues labs across the pharmaceutical, biotech, and research industries, turning straightforward quality control into a high-stakes guessing game.

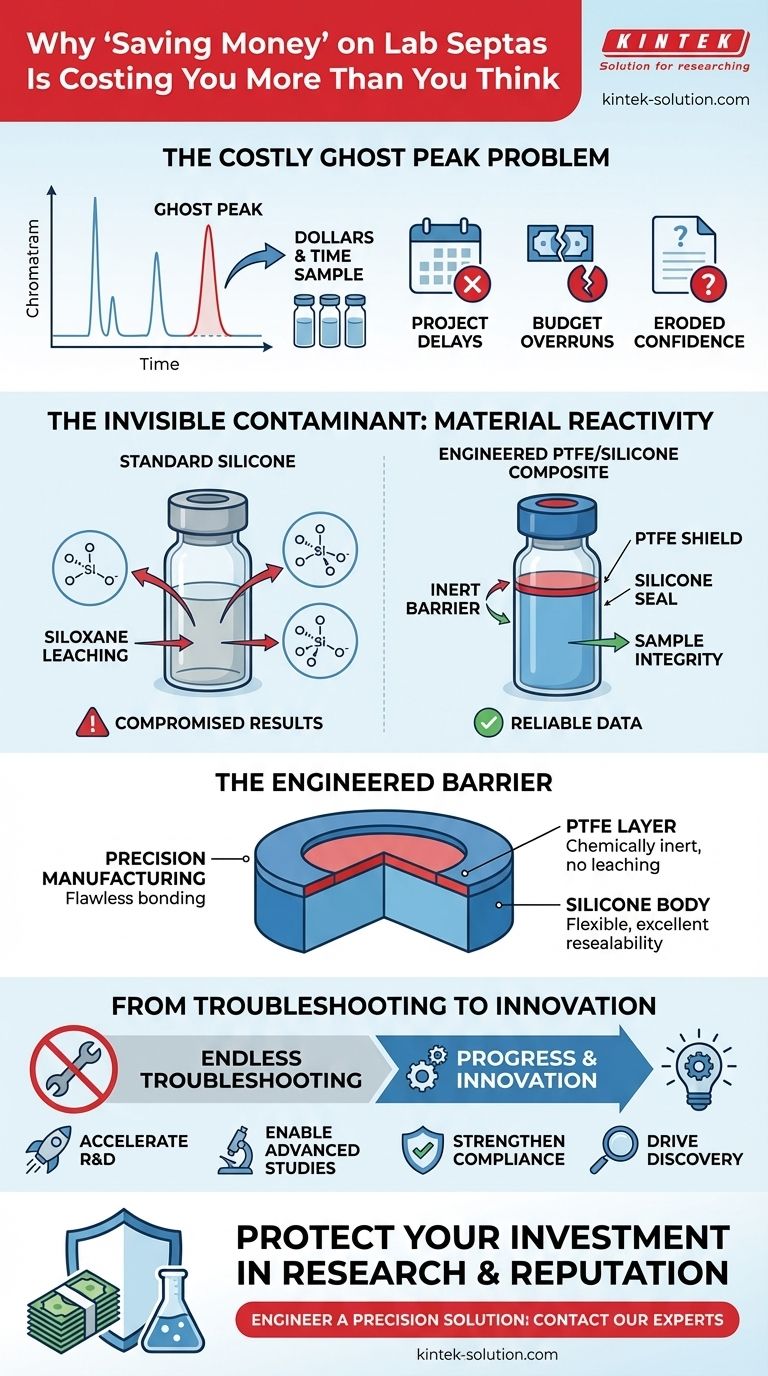

The Costly Checklist: Chasing Symptoms Instead of Causes

When faced with unreliable data, the troubleshooting checklist begins. Was it the solvent? The sample preparation? Does the instrument need recalibration?

Lab teams spend hours, sometimes days, rerunning analyses. They consume expensive solvents, burn through precious reference standards, and occupy valuable instrument time on multi-million dollar machines.

These aren't just scientific annoyances; they are significant business problems:

- Project Delays: A two-day troubleshooting session can derail a week-long sprint, pushing back critical development timelines.

- Budget Overruns: The cost of wasted materials, standards, and man-hours quickly adds up, eating into R&D and operational budgets.

- Eroded Confidence: Most importantly, inconsistent results undermine the integrity of your entire process. If you can't trust your data, how can you confidently move a drug candidate forward or release a product batch?

Many labs try to mitigate this by standardizing their procedures or increasing instrument maintenance. While these are good practices, they often fail to solve the problem. Why? Because they are focused on the process, not the source of the problem.

The Invisible Contaminant: It’s Not Your Method, It’s Your Material

After exhausting all the usual suspects, the investigation often leads to a surprising culprit: the tiny, seemingly insignificant septum sealing your sample vial.

The common assumption is that a septum is just a simple plug. The reality is that it's an active component in your analytical system. The root of the problem isn't your method or your machine. It's a fundamental material science issue: chemical reactivity.

Most standard, low-cost septas are made of silicone. While silicone provides an excellent physical seal, it is not chemically inert. Over time, or when in contact with certain solvents, it can leach trace amounts of chemicals called siloxanes directly into your sample.

This is the "ghost" in your machine. The leached siloxanes show up as unexpected peaks in your analysis, contaminating your results. Conversely, if your septum's material is reactive, it might absorb a tiny amount of your analyte, artificially lowering its measured concentration.

This is precisely why the common troubleshooting steps fail. They address the symptoms (bad data) but do nothing to stop the invisible contamination happening inside the vial. You can recalibrate your instrument a dozen times, but you will get the same flawed result if the sample itself is compromised before it ever reaches the injector.

An Engineered Barrier: The Role of Precision PTFE

To solve this problem at its core, you don't need a better troubleshooting protocol; you need a better material barrier. The solution must provide a perfect seal without reacting with the sample.

This is where a composite PTFE/silicone septum becomes essential. It's not just a single piece of material, but an engineered solution:

- The silicone body provides the mechanical flexibility and excellent resealability needed to withstand needle punctures.

- A thin, laminated PTFE (polytetrafluoroethylene) layer faces the sample, acting as a completely inert shield.

PTFE is one of the most non-reactive materials known to science. It will not leach into your sample, nor will it absorb your analyte. It creates a pristine environment inside the vial, ensuring that the sample you analyze is the sample you prepared.

But the material alone is not enough. The seal must be perfect. Even the smallest imperfection in manufacturing can lead to leaks, sample evaporation, and atmospheric contamination—rendering the inertness of PTFE useless. This is why at KINTEK, our focus extends beyond just using the right material. We are dedicated to precision manufacturing. A perfectly formed and bonded PTFE layer ensures a flawless seal, vial after vial, eliminating the variables that lead to analytical failure. Our components are designed from the ground up based on this deep understanding of material science, providing a reliable barrier you can trust.

From Troubleshooting to Innovation: What's Possible with Reliable Data

When you eliminate the phantom variable of sample contamination, the entire dynamic of your lab shifts. The focus moves from damage control to genuine progress.

With data you can trust implicitly, you unlock new potentials:

- Accelerate R&D: Your team can make faster, more confident decisions, moving promising candidates through the pipeline without the constant second-guessing caused by unreliable data.

- Enable Advanced Studies: Long-term stability studies and trace-level analyses that were previously too risky or difficult become feasible, as the threat of contamination over time is removed.

- Strengthen Regulatory Compliance: You can face audits from bodies like the FDA with a robust and defensible data record, knowing your components meet the highest standards of integrity.

- Drive Innovation: By freeing your best scientists from repetitive troubleshooting, you empower them to focus on what they do best: discovery and innovation.

Ultimately, investing in the right component is not about the cents you save on a single part. It’s about protecting the millions of dollars invested in your research, your products, and your reputation.

The principle of material integrity extends far beyond septas, impacting everything from chemical processing liners to medical device seals. If your projects demand absolute reliability and non-reactivity, your choice of material components is one of the most critical decisions you will make. Whether you're battling process contamination, ensuring biocompatibility, or scaling from a prototype to full production, our team of experts can help you engineer a precision PTFE solution that protects your work and your investment. Let's discuss your unique challenges and how to solve them at their root cause. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

Related Articles

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- The Unseen Component: How PTFE Became the Bedrock of Medical Device Reliability

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives