You’ve done everything right. You specified a "high-purity," "chemically resistant" component for your critical fluid handling system. Yet, you’re staring at the results of a catastrophic failure: an entire batch of semiconductor wafers ruined by micro-contamination, a pharmaceutical line halted due to a compromised seal, or a dangerous leak in a chemical processing plant.

The cost is immense, not just in lost product, but in downtime, frantic troubleshooting, and damaged reputation. You blame the component, find a slightly different alternative, and hope for the best. But the problem often comes back. It feels like you're chasing a ghost in the machine.

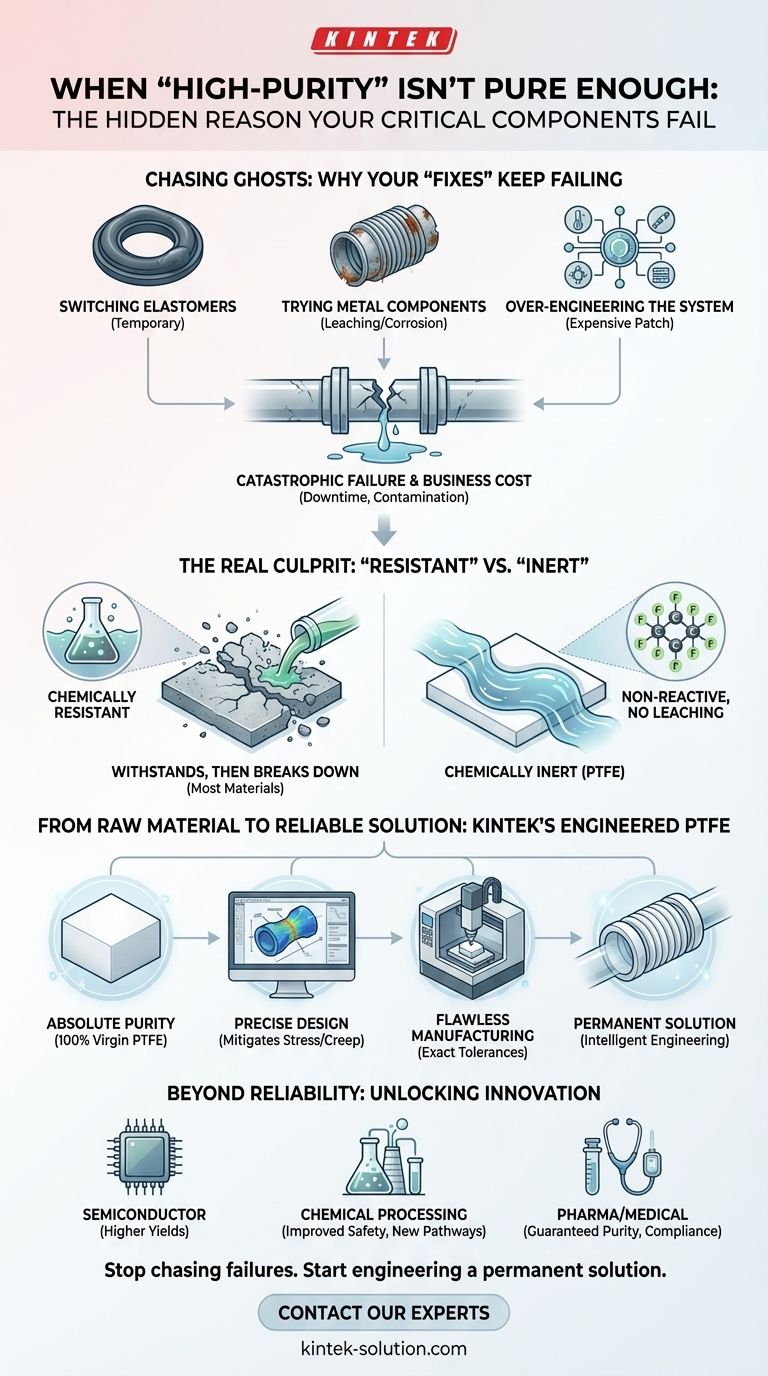

Chasing Ghosts: Why Your "Fixes" Keep Failing

If this scenario sounds familiar, you're not alone. In industries where performance is non-negotiable—like semiconductor, medical, and chemical processing—engineers are locked in a constant battle for process integrity. When a flexible joint, seal, or liner fails, the reaction is often a frantic search for a quick replacement.

The typical troubleshooting playbook looks something like this:

- Switching Elastomers: You swap one "chemically resistant" rubber or plastic for another, hoping the new material holds up better. It might work for a while, but eventually, it swells, degrades, or leaches unseen contaminants back into your system.

- Trying Metal Components: You opt for a stainless steel bellow, thinking it's indestructible. But then you encounter issues with ion leaching in an ultra-pure process or discover that aggressive acids are causing subtle but critical corrosion over time.

- Over-Engineering the System: You add extra filters, sensors, and monitoring equipment to catch failures before they happen. You're no longer solving the problem; you're just building a more expensive system to manage it.

These "solutions" are really just temporary patches. They fail because they address the symptom (a broken part) instead of the underlying disease. The business consequences are severe and recurring: project delays, spiraling operational costs, and an ever-present risk to product quality and safety.

The Real Culprit: The Difference Between "Resistant" and "Inert"

Here is the turning point. The fundamental reason these components repeatedly fail is a common misunderstanding of material science in zero-tolerance environments. You haven't been choosing the wrong components; you've been using the wrong category of material.

Most materials are merely chemically resistant. This means they can withstand a chemical attack for a certain period before they begin to break down, swell, or leach. For many industrial applications, this is good enough.

But in your world, "good enough" is a recipe for disaster. Your process demands a material that is chemically inert.

An inert material doesn't fight a chemical battle; it simply doesn't participate in the reaction at all. Think of it like a spectator at a chaotic event, completely unaffected. Polytetrafluoroethylene (PTFE) is the prime example of such a material. Its unique molecular structure, a fortress of tightly bonded carbon and fluorine atoms, makes it virtually non-reactive to almost all chemicals. It doesn’t leach, it doesn’t corrode, and it doesn’t contaminate.

The "fixes" mentioned earlier fail because they rely on materials that are merely resistant. Over time, under the stress of aggressive chemicals, extreme temperatures, or constant flexing, they inevitably give in. A PTFE component, when properly designed and manufactured, does not.

From Raw Material to Reliable Solution: Engineering the Perfect PTFE Component

However, simply choosing PTFE is not the whole story. The source article mentions that PTFE can be susceptible to "creep" (cold flow) under load. This is not a flaw in the material itself, but a failure of design and manufacturing.

To truly solve the problem, you need more than just a piece of PTFE. You need a component that has been intelligently engineered by specialists who understand the material's unique behavior. You need a solution where:

- Purity is Absolute: The component is fabricated from 100% virgin, high-purity PTFE resin, ensuring there are no additives or recycled materials that could become a source of contamination.

- Design is Precise: The component’s geometry, wall thickness, and convolution profile are specifically designed to handle your application's pressure, temperature, and movement, mitigating stresses that could lead to failure or creep.

- Manufacturing is Flawless: The part is machined to exact tolerances, creating a perfect seal and fit that eliminates weak points.

Why a KINTEK Component is Not Just Another PTFE Part

This is where we come in. At KINTEK, we don't just sell PTFE parts; we engineer PTFE solutions. We recognize that in your world, a component is not a commodity—it's a critical enabler of your entire process. Our precision production process is built on a deep understanding of PTFE's properties. We partner with you to design and fabricate custom components, from a single prototype to high-volume orders, ensuring that the part you receive is the permanent solution to the problem you're facing. We deliver the inertness of PTFE, fortified with the intelligence of expert engineering.

Beyond Reliability: What New Frontiers Can You Explore?

When you stop wasting time and resources chasing component failures, what becomes possible?

Freed from the constant worry of contamination and downtime, you can finally focus on innovation.

- Semiconductor fabs can push the limits of their etching and cleaning processes, developing next-generation chips with higher yields and greater confidence.

- Chemical plants can extend maintenance cycles, improve operational safety, and explore more aggressive or efficient chemical pathways that were previously too risky.

- Pharmaceutical and medical device manufacturers can guarantee batch-to-batch purity and integrity, accelerating time-to-market and simplifying regulatory compliance.

Solving this persistent component problem doesn't just bring you back to baseline; it unlocks a new level of performance, efficiency, and innovation.

Your process has unique demands, and your challenges require more than an off-the-shelf part. It's time to stop applying temporary fixes and start engineering a permanent solution. Let our team of specialists help you design a PTFE component that eliminates risk and unlocks new potential for your projects. Contact Our Experts to start the conversation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure