It’s 3 AM on a North Sea oil platform. An alarm blares. A critical flange connection shows a pressure drop. A maintenance engineer, battered by wind and sea spray, puts a wrench on a series of bolts that haven’t been touched in five years.

The first bolt is seized, its head rounded by corrosion. The second shears off under torque. The system failure isn't the leaking gasket; it's the simple, overlooked fastener that now stands between control and catastrophe.

This scenario isn’t a failure of material strength. It's a failure of foresight—a miscalculation of the invisible forces of friction and chemistry that relentlessly degrade mechanical assemblies. It highlights a psychological blind spot in engineering: we often prioritize the calculated strength of a component over its long-term, real-world resilience.

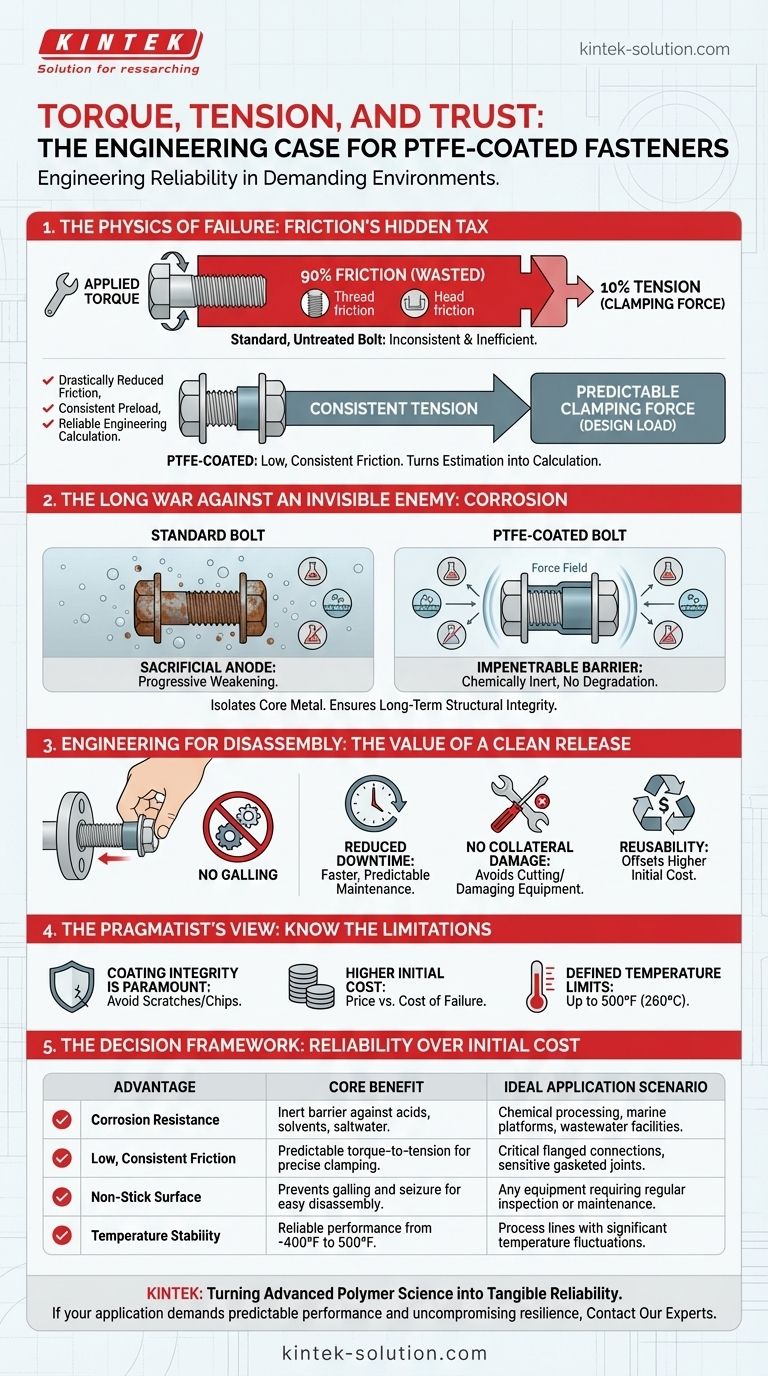

The Physics of Failure: Friction's Hidden Tax

When an engineer tightens a bolt, their goal is not torque. Their goal is tension, or preload—the clamping force that holds a joint together.

Yet, on a standard, untreated bolt, up to 90% of the applied torque is consumed simply by overcoming friction in the threads and under the head. This isn't just inefficient; it's dangerously inconsistent. The friction varies based on surface finish, lubrication, and corrosion, making the relationship between the torque you measure and the tension you achieve a matter of guesswork.

This is the first problem that Polytetrafluoroethylene (PTFE) coatings solve with an almost beautiful elegance.

PTFE has one of the lowest coefficients of friction of any solid material. By coating a fastener, you drastically reduce this "friction tax." More importantly, you make it consistent. The torque applied translates directly and predictably into bolt tension, ensuring every fastener in a pattern carries its designed load. This transforms a high-stakes estimate into a reliable engineering calculation.

The Long War Against an Invisible Enemy

Mechanical components exist in a constant state of war with their environment. In chemical plants, marine environments, or even semiconductor cleanrooms, aggressive acids, saltwater, and solvents wage a slow, relentless attack.

Corrosion isn't just a cosmetic issue; it's a progressive weakening of a material's structural integrity. A standard bolt acts as a sacrificial anode, slowly dissolving until it can no longer bear its load.

Here, PTFE's second core property comes into play: it is almost completely chemically inert. A PTFE coating acts as an impenetrable barrier, isolating the core metal from the hostile environment. It doesn’t rust, degrade, or react. It simply endures, ensuring the fastener’s mechanical properties remain intact for years.

Engineering for Disassembly: The Value of a Clean Release

A well-engineered system is not only defined by how it is assembled but also by how it can be disassembled. Maintenance is not an afterthought; it is a planned part of a component's lifecycle.

The non-stick nature of PTFE prevents galling, a form of adhesive wear where fastener threads seize under pressure, a common nightmare with stainless steel. For the engineer on the oil rig, this means a bolt that comes off cleanly and easily, even after a decade of service.

This single property translates into:

- Reduced Downtime: Maintenance is faster and more predictable.

- No Collateral Damage: Seized bolts don't have to be cut off, which risks damaging expensive flanges or equipment.

- Reusability: Fasteners can often be reused, offsetting their higher initial cost.

The Pragmatist's View: Know the Limitations

PTFE-coated fasteners are a specialized solution, not a universal one. Acknowledging their trade-offs is crucial for proper application.

- Coating Integrity is Paramount: The PTFE layer is relatively soft. Improper tools or careless handling can scratch or chip the coating, creating a breach point for corrosion to begin.

- Higher Initial Cost: The specialized coating process makes these fasteners more expensive upfront than standard zinc-plated bolts. This is a classic "price vs. cost" decision. The price is paid once; the cost of failure or difficult maintenance is paid repeatedly.

- Defined Temperature Limits: PTFE performs exceptionally well up to 500°F (260°C), but it is not suitable for extreme-heat applications like furnace or engine exhaust components.

The Decision Framework: Reliability Over Initial Cost

Choosing the right fastener is an exercise in risk management. The decision hinges on the consequences of failure and the value of predictability.

| Advantage | Core Benefit | Ideal Application Scenario |

|---|---|---|

| Corrosion Resistance | An inert barrier against acids, solvents, and saltwater. | Chemical processing, marine platforms, wastewater facilities. |

| Low, Consistent Friction | Predictable torque-to-tension for precise clamping. | Critical flanged connections, sensitive gasketed joints. |

| Non-Stick Surface | Prevents galling and seizure for easy disassembly. | Any equipment requiring regular inspection or maintenance. |

| Temperature Stability | Reliable performance from -400°F to 500°F. | Process lines with significant temperature fluctuations. |

Ultimately, specifying a PTFE-coated fastener is a declaration that long-term reliability, safety, and ease of maintenance are more important than minimizing the initial bill of materials.

Solving these systemic challenges requires more than just choosing a coating; it demands a manufacturing partner who understands the nuances of material science and precision fabrication. At KINTEK, we specialize in creating custom PTFE components—from high-integrity seals and liners to coated fasteners—for the world's most demanding industries, including semiconductor, medical, and industrial processing. We turn advanced polymer science into tangible reliability.

If your application demands predictable performance and uncompromising resilience, Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions