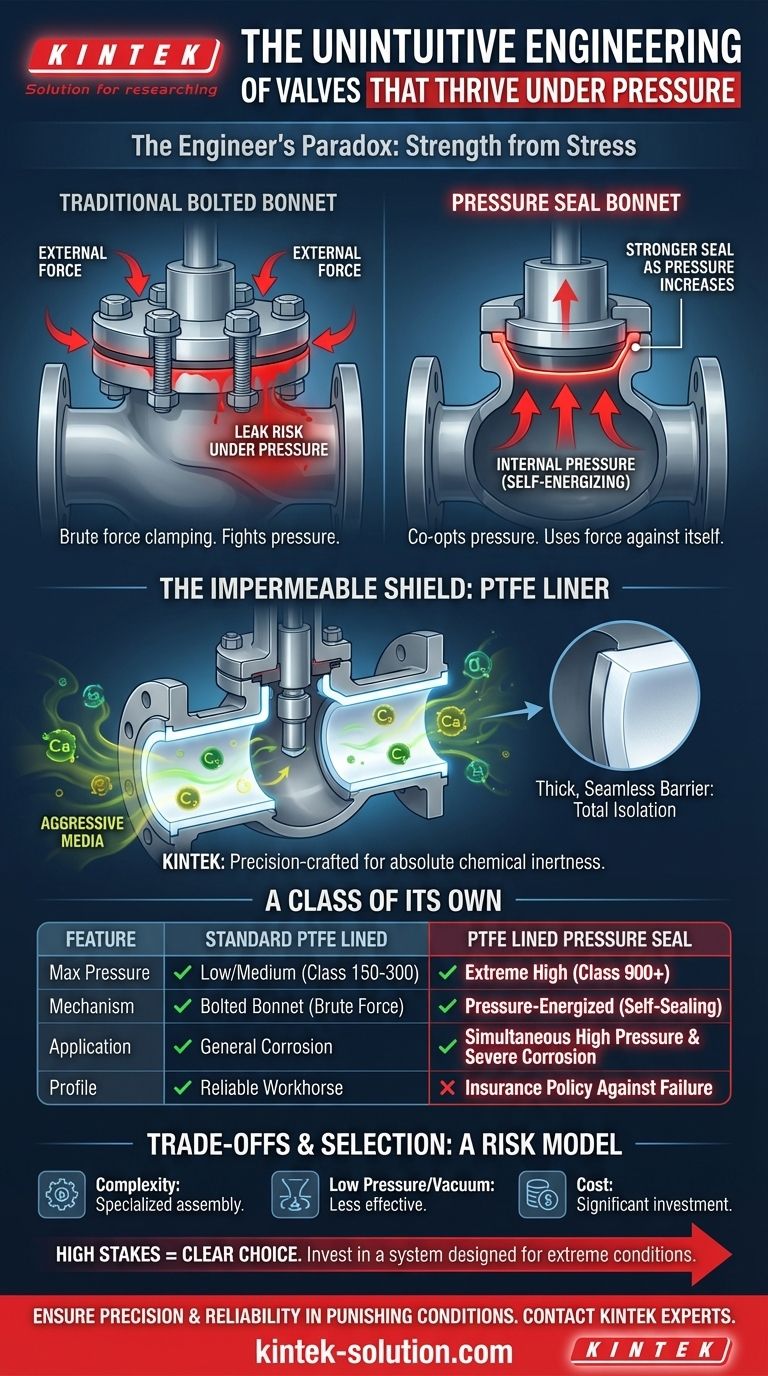

The Engineer's Paradox: Strength from Stress

In most mechanical systems, pressure is the enemy. It's a relentless force that seeks out weaknesses, fatiguing materials and exploiting the slightest flaw in a seal. We spend immense effort designing systems to resist it, often through brute force—thicker walls, more bolts, stronger materials.

But what if you could invert the problem? What if the very pressure trying to tear a system apart could be harnessed to hold it together?

This is the elegant, counter-intuitive principle behind the pressure seal valve. It’s a design philosophy that shares more in common with a submarine hatch than a traditional industrial valve. The deeper the submarine goes, the greater the external water pressure, and the tighter the hatch seals against its frame. The system becomes stronger precisely because the stress upon it increases.

When you combine this brilliant mechanical concept with a defense against chemical attack, you get a unique solution for the most hostile environments on earth: the PTFE Lined Pressure Seal Valve.

Deconstructing the Design: Two Problems, One Solution

This valve is not just a component; it's a strategic answer to two distinct, often simultaneous, industrial challenges: immense mechanical pressure and severe chemical corrosion.

To appreciate its design, you must look at its two core technologies not as separate features, but as a synergistic system.

Part 1: Using Force Against Itself - The Pressure Seal Bonnet

A standard valve uses a "bolted bonnet." The concept is simple: use a ring of bolts to squeeze a gasket between the valve body and its lid, hoping the clamping force is enough to contain the pressure inside. It's a contest of brute strength.

The pressure seal design is more sophisticated.

- As internal pressure builds, it pushes the bonnet upward.

- This upward force presses a tapered, specialized gasket into a tapered recess in the valve body.

- The higher the pressure, the more intensely the gasket is wedged into place, creating an exponentially tighter seal.

The bolts are only there to create an initial seal at low pressure. The system's own energy does the heavy lifting, creating a dynamic, self-energizing seal that is inherently safer for high-pressure service.

Part 2: The Impermeable Shield - The PTFE Liner

While the pressure seal mechanism handles mechanical stress, the internal PTFE lining tackles the chemical threat. This isn't just a thin coating; it's a thick, seamless barrier of Polytetrafluoroethylene that completely isolates the valve's metal body from the process media.

The integrity of this liner is everything. A single microscopic pinhole or imperfection would allow corrosive chemicals to attack the structural steel, rendering the valve's pressure-handling capabilities useless.

This is where material science and manufacturing precision become paramount. Crafting a flawless, dimensionally perfect PTFE liner—one that can withstand thermal cycling and mechanical stress without failing—is a specialized discipline. At KINTEK, we focus exclusively on this challenge, producing high-purity, custom-fabricated PTFE components like these liners and seals, ensuring they provide the absolute chemical inertness and non-stick performance required in these critical applications.

A Class of Its Own: When Other Lined Valves Fall Short

Understanding where this valve fits requires acknowledging the limits of more common designs. The choice is less about which is "best" and more about matching the tool to the specific level of risk.

| Feature | Standard PTFE Lined Valve | PTFE Lined Pressure Seal Valve |

|---|---|---|

| Max Pressure Rating | Low to Medium (e.g., ASME Class 150-300) | Extreme High Pressure (e.g., ASME Class 900+) |

| Primary Sealing Mechanism | Bolted Bonnet (Brute Force) | Pressure-Energized Bonnet (Self-Sealing) |

| Ideal Application | General Corrosion Resistance | Simultaneous High Pressure & Severe Corrosion |

| Psychological Profile | A reliable workhorse for known conditions. | An insurance policy against catastrophic failure. |

Standard lined gate, plug, or butterfly valves are excellent for managing corrosion in low-to-medium pressure systems. But they rely on the brute-force bolted bonnet, which has a practical ceiling. For the extreme energies found in power generation or severe chemical processing, you need a design that doesn't fight the pressure but co-opts it.

The Inevitable Trade-Offs

No engineering solution is perfect, and this specialized design comes with clear compromises. Acknowledging them is key to using it correctly.

- Complexity: The pressure seal mechanism is more complex to assemble and service than a simple bolted bonnet. The specialized gaskets require careful handling.

- Minimum Pressure: Because the design leverages system pressure, its sealing performance can be less effective in very low-pressure or vacuum scenarios.

- Cost: This is a high-performance, specialized piece of equipment. The combination of a pressure seal body and a high-integrity, precision-molded PTFE lining from a specialist like KINTEK makes it a significant investment.

A Mental Model for Selection

The decision to specify a PTFE Lined Pressure Seal Valve is ultimately a calculation of risk.

Ask yourself: what is the cost of failure?

If your primary challenge is corrosion in a low-pressure environment, a standard lined valve is a more practical, cost-effective choice. If it's high pressure with a non-corrosive fluid, a standard pressure seal valve suffices.

But if you face both extreme pressure and aggressive media simultaneously—where a seal breach could be catastrophic—the choice becomes clear. You are no longer just buying a valve; you are investing in a system designed to become more reliable as conditions become more severe.

It’s an elegant solution engineered for the edge cases, ensuring safety and longevity where other designs cannot. If your system operates in these punishing conditions, ensuring every component meets the highest standards of precision is critical. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics