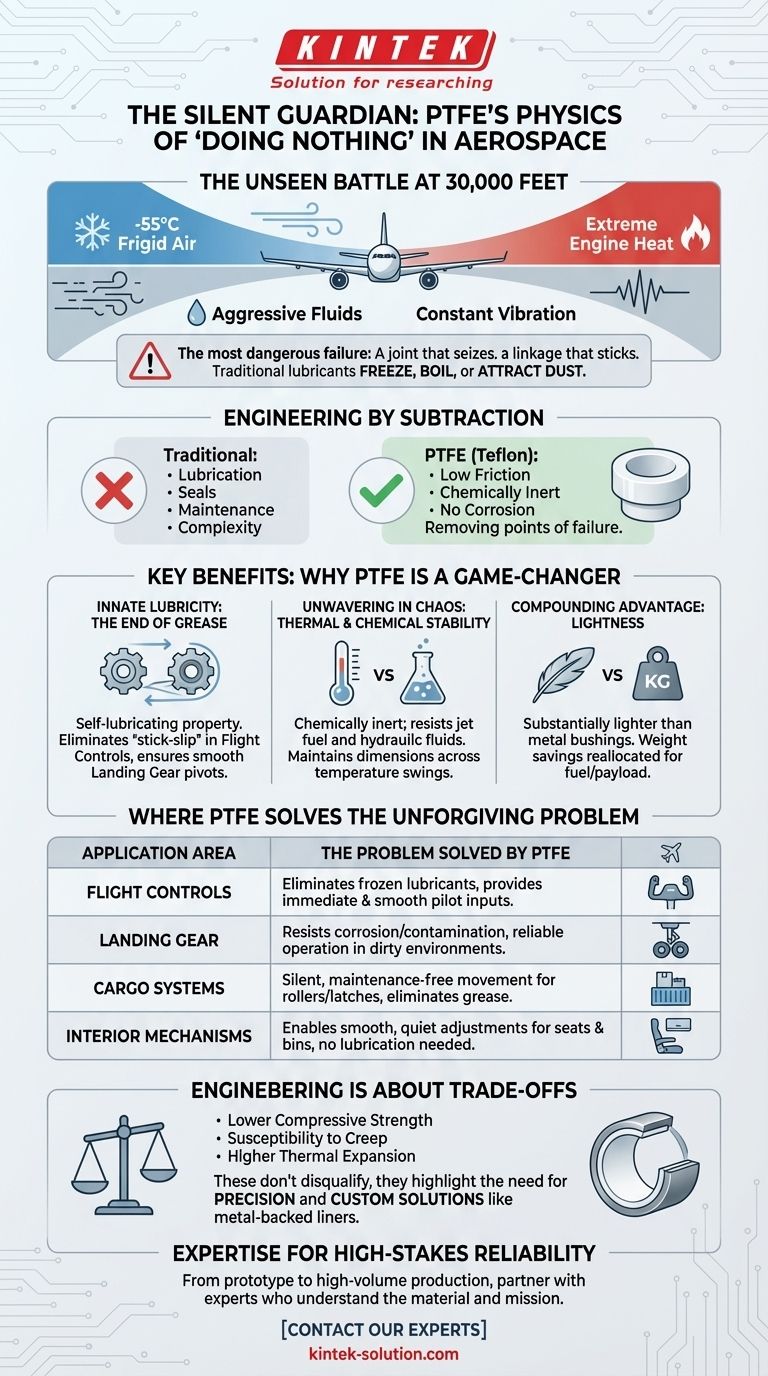

The Unseen Battle at 30,000 Feet

An aircraft is a marvel of managing extremes. At cruising altitude, the outside air is a frigid -55°C. Near the engines, temperatures can soar. During flight, its systems are bathed in aggressive hydraulic fluids and subject to constant vibration.

In this hostile world, the most dangerous failure is often the most mundane: a joint that seizes, a linkage that sticks.

The traditional solution—grease and oil—becomes a liability. Lubricants can freeze solid, boil away, or attract abrasive dust that grinds down critical components. This isn't just a maintenance problem; it's a fundamental risk to a system where reliability is measured in fractions of a percent.

The solution, it turns out, is not a better lubricant, but a material that makes lubrication obsolete.

A Different Philosophy: Engineering by Subtraction

The brilliance of Polytetrafluoroethylene (PTFE), commonly known as Teflon, in aerospace is not what it does, but what it doesn't do. It doesn't corrode, it doesn't need oil, and it doesn't seize across vast temperature swings.

It solves problems by removing the points of failure. This is a psychological shift for engineers: designing not by adding complexity (lubrication systems, seals, maintenance schedules), but by subtracting it.

Innate Lubricity: The End of Grease

PTFE has one of the lowest coefficients of friction of any solid material. Parts glide against each other with an effortless smoothness that is inherent to the material itself.

This self-lubricating property is a game-changer.

- In flight control linkages, it eliminates "stick-slip" behavior, ensuring the pilot's inputs translate into immediate, predictable actions without lag or resistance.

- In landing gear pivots, it guarantees smooth deployment after being exposed to runway grit, de-icing fluids, and ground-level temperature extremes. The joint works reliably without a drop of grease.

Unwavering in Chaos: Thermal and Chemical Stability

The true value of an aerospace component is its predictability. PTFE is almost entirely chemically inert. It simply does not react with jet fuel, Skydrol hydraulic fluid, or other corrosive agents. It will not swell, soften, or degrade.

Simultaneously, it maintains its dimensions and performance from the cold soak of high altitude to the heat of a tarmac in summer. This stability ensures that precision-engineered tolerances are held, and a joint that moves freely on the ground will move just as freely in the sky.

The Compounding Advantage of Lightness

In aerospace, weight is a constant tax on performance. Every gram saved is a gram that can be reallocated to fuel, payload, or efficiency.

PTFE bushings are substantially lighter than the bronze or steel bearings they often replace. While one bushing is a small victory, hundreds of them across an airframe add up to a significant, compounding advantage.

Where PTFE Solves the Unforgiving Problem

These properties converge to solve specific, high-stakes challenges where failure is not an option.

| Application Area | The Problem Solved by PTFE |

|---|---|

| Flight Controls | Eliminates the risk of frozen lubricants, providing immediate and smooth response for pilot inputs. |

| Landing Gear | Resists corrosion and contamination, ensuring reliable operation in one of the aircraft's dirtiest environments. |

| Cargo Systems | Provides silent, maintenance-free movement for rollers and latches, eliminating grease that can soil luggage. |

| Interior Mechanisms | Enables smooth, quiet adjustments for seats and overhead bins without the need for periodic lubrication. |

Engineering is About Trade-offs

No material is a panacea. PTFE's strengths are balanced by limitations that every engineer must account for.

-

Lower Compressive Strength: Compared to steel, PTFE is soft. It cannot bear the same extreme static loads without deforming. The solution is often a composite design, like a metal-backed bushing, where a steel shell provides structural strength and a thin PTFE liner provides the low-friction surface.

-

Susceptibility to Creep: Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon must be calculated and designed for to ensure critical tolerances are maintained over the aircraft's multi-decade service life.

-

Higher Thermal Expansion: PTFE expands and contracts with temperature changes more than metals do. The design of the housing and joint must accommodate this movement to prevent the bushing from binding or becoming loose.

These trade-offs don't disqualify the material; they highlight the need for precision. The success of a PTFE component is as much in the design and manufacturing as it is in the raw material itself.

This is where expertise in fabrication becomes critical. Achieving the perfect fit, accounting for thermal expansion, and creating custom solutions like metal-backed liners are what transform a remarkable polymer into a reliable aerospace-grade component. For systems that demand this level of precision and custom engineering, you need a partner who understands the material and the mission.

When reliability is paramount, from prototype to high-volume production, ensuring your components are engineered to perfection is the only path forward. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

Related Articles

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Your "Inert" PTFE Component Might Be the Real Source of System Failure