The Psychology of Trust in Data

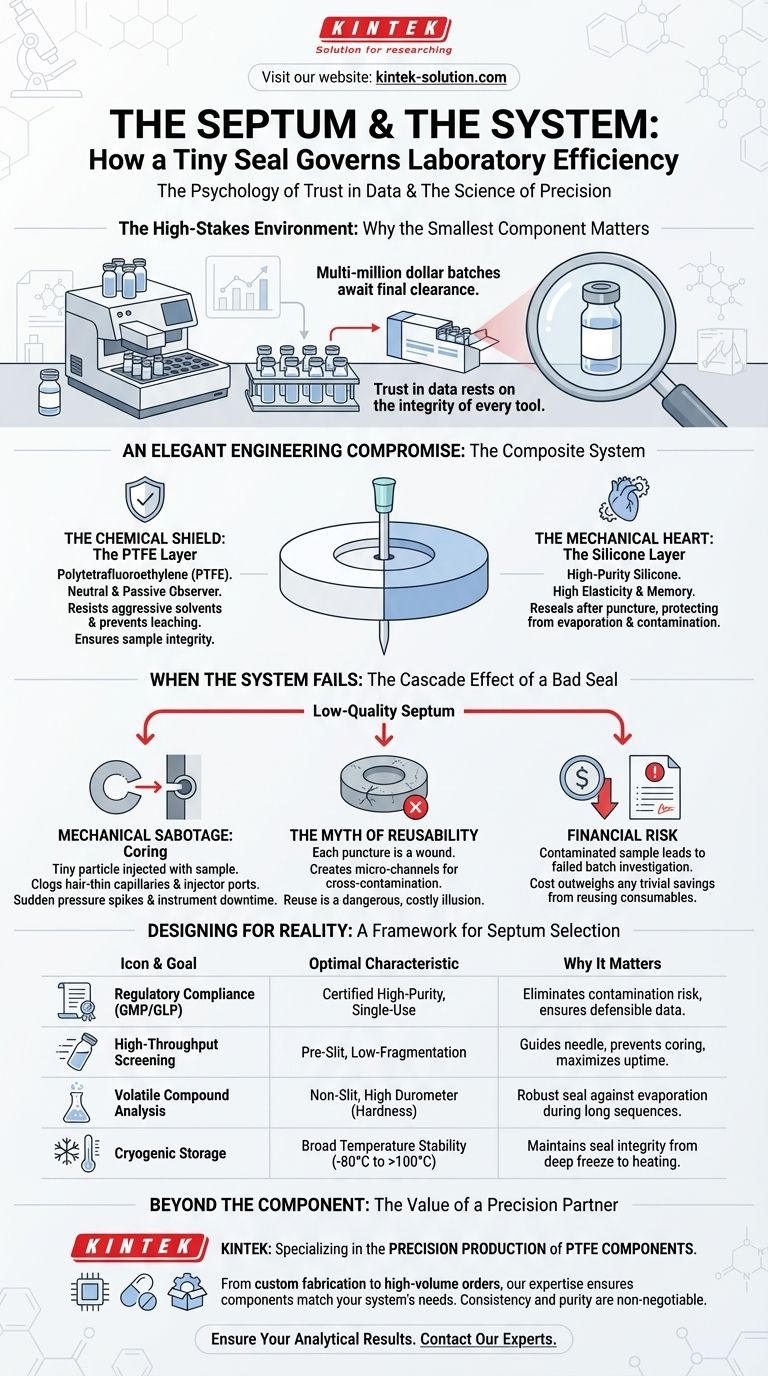

Imagine a multi-million dollar pharmaceutical batch awaiting its final quality control clearance. An analyst loads a series of vials into an HPLC autosampler, a machine engineered for micron-level precision. The entire validation of the batch, and the trust in the product, rests on the data this machine will generate over the next few hours.

In this high-stakes environment, we focus on the complex chemistry and the sophisticated machinery. Yet, the single greatest point of vulnerability might be the smallest, most overlooked component in the entire workflow: the thin septum sealing the vial.

The failure of this tiny seal introduces doubt. And in scientific analysis, doubt is a catastrophic cost, forcing re-runs, quarantine, and investigation. The integrity of our data is built on a foundation of trust in our tools, starting with the most basic.

An Elegant Engineering Compromise

The core function of a septum is to solve two contradictory problems: it must allow a needle to pass through it, yet it must also maintain a perfect seal before, during, and after that event. The PTFE/silicone septum is an elegant solution born from this engineering challenge.

It’s not one material, but a composite system. Each layer has a single, critical job.

The Chemical Shield: The PTFE Layer

Facing the sample is a micro-thin layer of Polytetrafluoroethylene (PTFE). Its role is one of perfect neutrality. In the world of aggressive solvents and sensitive drug formulations, PTFE is the ultimate passive observer. It does not react, it does not leach, it does not contaminate. It ensures the sample you analyze is the sample you prepared.

The Mechanical Heart: The Silicone Layer

Behind the PTFE shield lies a thicker, softer layer of silicone. This is the mechanical engine of the septum. Its high-purity elasticity allows a needle to pierce it with minimal force. More importantly, it has a "memory." After the needle withdraws, the silicone reseals the puncture path, protecting the sample from the outside world once more.

This resealing is not trivial. It prevents solvent evaporation that could falsely concentrate a sample, rendering the resulting data precisely wrong.

When the System Fails: The Cascade Effect of a Bad Seal

A modern analytical laboratory is a finely tuned system. When one small component fails, the consequences cascade, leading to failures far more expensive than the part itself. A low-quality septum is a common agent of this chaos.

Mechanical Sabotage: Coring and Downtime

When a needle punctures a poorly made septum, it can punch out a tiny piece of the material, a phenomenon called "coring." This small particle is then injected along with the sample directly into the heart of the analytical instrument.

This single fleck can clog the hair-thin capillaries of an HPLC or the injector port of a GC. The result is a sudden pressure spike, a failed sequence, and an instrument that is out of commission. The marvel of engineering, worth hundreds of thousands of dollars, is brought to a halt by a component that costs pennies. This is why precision production isn't a luxury; it's a fundamental requirement for system reliability.

The Myth of Reusability

In a regulated environment (GMP/GLP), the idea of reusing a septum to save costs is a dangerous illusion. Each puncture is a wound. Even with excellent resealing, it creates a potential micro-channel for cross-contamination.

The financial risk of a single contaminated sample leading to a failed batch investigation far outweighs any trivial savings from reusing consumables. The most efficient labs recognize that true economy comes from eliminating variables, not from reusing parts designed for single, critical use.

Designing for Reality: A Framework for Septum Selection

Choosing the right septum is not about finding the "best" one, but the correct one for the task at hand. The objective dictates the design.

| Analytical Goal | Optimal Septum Characteristic | Why It Matters |

|---|---|---|

| Regulatory Compliance (GMP/GLP) | Certified High-Purity, Single-Use | Eliminates any risk of contamination, ensuring data is defensible for audits. |

| High-Throughput Screening | Pre-Slit, Low-Fragmentation | Guides the needle to prevent coring, maximizing instrument uptime and run success. |

| Volatile Compound Analysis | Non-Slit, High Durometer (Hardness) | Provides the most robust seal against evaporation during long analytical sequences. |

| Cryogenic Storage | Broad Temperature Stability (-80°C to >100°C) | Maintains seal integrity from deep freeze to heating, preserving the sample. |

This level of specificity often moves beyond off-the-shelf solutions. For unique instruments or particularly sensitive assays, the ability to specify the exact material, durometer, and configuration becomes critical.

Beyond the Component: The Value of a Precision Partner

A vial septum is not a commodity. It is a critical component whose performance is directly linked to data integrity, instrument health, and overall laboratory throughput. Therefore, the manufacturer you choose is more than a supplier; they are a partner in your scientific mission.

At KINTEK, we specialize in the precision production of PTFE components. Our expertise, honed across demanding industries from semiconductors to medicine, is built on the understanding that consistency and purity are non-negotiable. We offer custom fabrication, from prototypes for new applications to high-volume orders for established workflows, ensuring your components are perfectly matched to your system's needs.

By focusing on the quality of the smallest parts, we help protect the integrity of the entire system. To ensure your analytical results are built on a foundation of certainty, Contact Our Experts.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

Related Articles

- The Physics of 'Fit and Forget': How PTFE Re-engineers Mechanical Systems

- The Specialist's Dilemma: Understanding the Critical Trade-offs of PTFE-Lined Valves

- Why Your Lab Plugs Stick and Contaminate: The Hidden Science of Surface Energy

- The Unbreakable Bond: Why PTFE Defines Chemical Containment and Purity

- The Hidden Cost of Chemical Containers: Why Yours Are Failing and How to Fix It