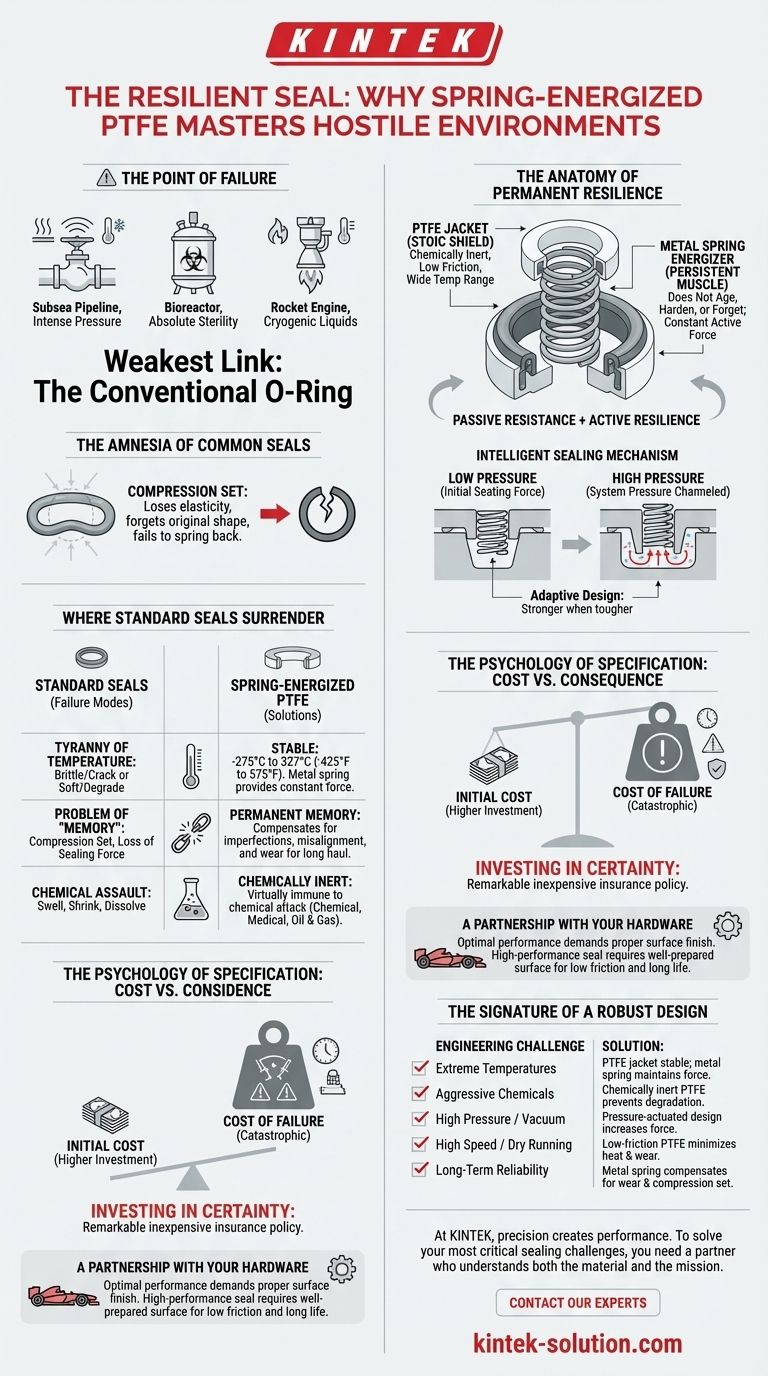

The Point of Failure

Imagine a valve on a subsea pipeline, miles below the surface. The pressure is immense, the temperature is near freezing, and the cost of a single failure is catastrophic.

Now, imagine a bioreactor processing a life-saving drug, where sterility is absolute. Or a rocket engine fuel pump, where cryogenic liquids meet violent forces.

In these scenarios, the weakest link is often the smallest, most overlooked component: the seal. And here, the conventional rubber O-ring reaches its physical limits.

The Amnesia of Common Seals

Standard elastomeric seals suffer from a form of material amnesia.

Over time, under constant pressure and temperature fluctuations, they experience "compression set." They lose their elasticity, forget their original shape, and fail to spring back. This is a quiet, gradual failure—a slow leak that becomes a critical breach.

This isn't a defect; it's the fundamental nature of the material. For applications where failure is not an option, a different engineering philosophy is required.

The Anatomy of Permanent Resilience

A spring-energized seal is an elegant solution born from this need. Its design is a partnership between two dissimilar materials, each covering the other's weaknesses.

A Tale of Two Materials

The design combines a precision-machined jacket, typically made of Polytetrafluoroethylene (PTFE), and a metal spring energizer.

- The PTFE Jacket acts as the stoic shield. It is chemically inert, unfazed by nearly any industrial fluid. It has an incredibly low coefficient of friction and a vast operating temperature range.

- The Metal Spring Energizer is the persistent muscle. Unlike an elastomer, it does not age, harden, or forget. It provides a constant, active mechanical force, ensuring the seal lips are always engaged.

The jacket provides the passive resistance; the spring provides the active resilience.

An Intelligent Sealing Mechanism

The genius of the design is how it uses the system's own energy to its advantage.

At low pressure, the spring provides the initial seating force, creating a tight seal. As system pressure increases, that pressure is channeled into the U-shaped cavity of the jacket, pushing the sealing lips against the hardware with immense force.

The seal gets stronger precisely when the challenge gets tougher. It is an inherently adaptive design.

Where Standard Seals Surrender

This synergy directly solves the failure modes that plague traditional seals in extreme environments.

The Tyranny of Temperature

Elastomers become brittle and crack at cryogenic temperatures or turn soft and degrade at high heat.

A spring-energized PTFE seal operates flawlessly from -275°C (-425°F) to 327°C (575°F). The PTFE jacket remains stable, and the metal spring continues to provide a constant sealing force, regardless of the thermal shock.

The Problem of "Memory"

As mentioned, elastomers suffer from compression set. The metal spring, by contrast, has a perfect, permanent memory.

This allows the seal to compensate for minor hardware imperfections, shaft misalignment, and, most importantly, the natural wear of the PTFE jacket over its long service life. It ensures reliability for the long haul.

The Chemical Assault

Aggressive solvents, acids, and bases will cause elastomers to swell, shrink, or dissolve.

The near-universal chemical inertness of PTFE means the seal is virtually immune to chemical attack, making it the default choice for chemical processing, medical devices, and oil & gas applications.

The Psychology of Specification: Cost vs. Consequence

While superior, these seals are specialized components. Their adoption requires a shift in engineering mindset from focusing on unit cost to focusing on the total cost of failure.

Investing in Certainty

A spring-energized seal has a higher initial cost than a simple O-ring. This often creates a moment of hesitation.

However, the true cost of a component is not its purchase price. It is the price of its failure. When you factor in the cost of downtime, product recalls, environmental cleanup, or safety incidents, the higher initial investment becomes a remarkably inexpensive insurance policy.

A Partnership With Your Hardware

Optimal performance demands a proper surface finish on the mating hardware. This isn't a flaw of the seal; it's a characteristic of any high-performance system.

You wouldn't put economy tires on a Formula 1 car. Similarly, a high-performance seal requires a well-prepared surface to deliver its full potential for low friction and long life.

The Signature of a Robust Design

Deciding to use a spring-energized seal is a clear indicator that reliability is a primary design driver. The choice becomes clear in several key scenarios.

| Engineering Challenge | How the Spring-Energized Seal Solves It |

|---|---|

| Extreme Temperatures | PTFE jacket remains stable; metal spring maintains constant force. |

| Aggressive Chemicals | Chemically inert PTFE jacket prevents degradation, swelling, or failure. |

| High Pressure / Vacuum | Pressure-actuated design uses system pressure to increase sealing force. |

| High Speed / Dry Running | Low-friction PTFE minimizes heat generation and wear. |

| Long-Term Reliability | Metal spring compensates for wear and eliminates compression set. |

Designing for extreme environments requires more than just a clever component; it demands manufacturing precision. The theoretical resilience of a spring-energized seal is only realized through exacting production standards and deep material expertise.

At KINTEK, we specialize in manufacturing custom PTFE components that transform robust designs into reliable realities. Whether for semiconductor, medical, or industrial applications, the principle remains the same: precision creates performance. To solve your most critical sealing challenges, you need a partner who understands both the material and the mission.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems