It’s a scenario every analytical scientist dreads. You return to the lab in the morning to check on an overnight HPLC run, only to find the sequence aborted at vial #3. Or worse, the run completed, but the chromatogram is littered with phantom peaks you can’t explain. You spend the rest of the day—or the rest of the week—in a frustrating cycle of troubleshooting, questioning everything from your mobile phase to your instrument calibration.

What if the source of this chaos isn't your multi-million dollar instrument or your carefully prepared standards, but a component that costs mere cents?

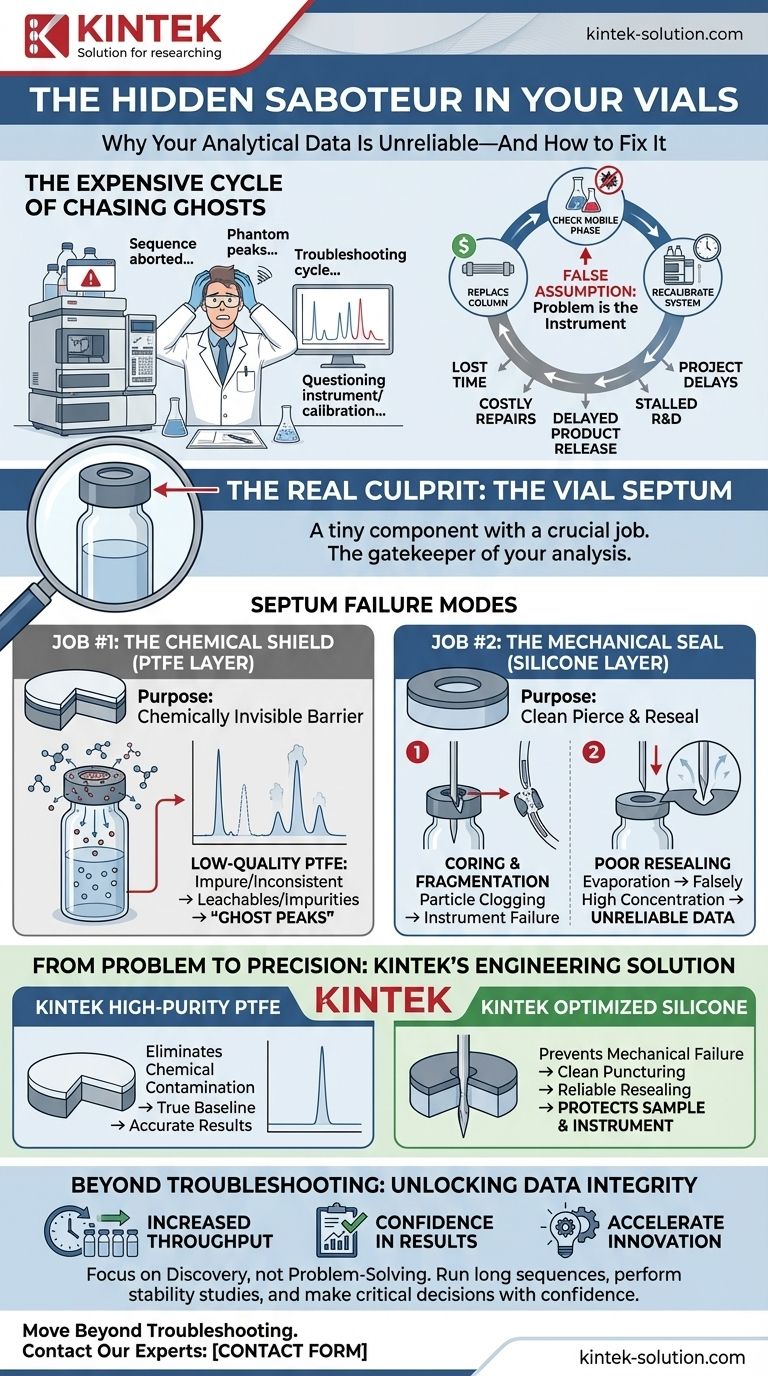

The Expensive Cycle of Chasing Ghosts

When analytical data goes haywire, the typical response is a frantic, and often fruitless, troubleshooting process. We check and re-check the usual suspects:

- "Maybe the mobile phase is contaminated." You spend hours preparing fresh solutions.

- "The column must be failing." You install a new, expensive column, hoping for the best.

- "Let's recalibrate the entire system." Another half-day of instrument time is lost.

While you're hunting for the problem, the real consequences are piling up. Project timelines are pushed back. R&D efforts stall. In a manufacturing environment, a questionable result can delay the release of a multi-million dollar product batch. And when tiny particles from a failing component clog a delicate needle or valve, you’re not just facing downtime; you’re facing a four-figure repair bill.

This endless cycle of guesswork is exhausting and expensive. But it’s based on a false assumption: that the problem lies within the analytical instrument itself. In reality, the problem often starts before your sample even begins its journey.

The Real Culprit: A Tiny Component with a Crucial Job

The integrity of your entire analysis rests on a small, unassuming disc of material: the vial septum. We often think of it as just a lid, but its role is far more active and critical. It’s a gatekeeper, and if it fails, nothing that happens downstream can be trusted.

A high-performance septum has to do two jobs perfectly, and failure in either one leads to disaster. This is why they are engineered with a sophisticated dual-layer design.

Job #1: The Chemical Shield (The PTFE Layer)

The ultra-thin layer that faces your sample is made of PTFE (polytetrafluoroethylene). Its sole purpose is to be chemically invisible. It must form a perfect, inert barrier that doesn't react with your sample, leach impurities into it, or absorb parts of it.

When you use a low-quality septum, this PTFE layer can be impure or inconsistent. Trace chemicals from the manufacturing process can leach into your sample, appearing as those mysterious “ghost peaks” in your analysis. Your instrument isn’t hallucinating; it’s accurately detecting the contamination your septum introduced.

Job #2: The Mechanical Seal (The Silicone Layer)

The thicker, rubbery layer is typically made of silicone. Its job is purely mechanical: it must allow the autosampler needle to pierce it cleanly and then reseal perfectly the instant the needle is withdrawn.

If the silicone is of poor quality, two things go wrong:

- Coring and Fragmentation: The needle punches out a tiny piece of the septum material, which falls into your sample. This particle can be drawn into the autosampler, clogging delicate tubing and leading to catastrophic instrument failure.

- Poor Resealing: If the septum doesn't seal tightly after being punctured, volatile solvents can evaporate. This changes the concentration of your sample, making your quantitative results falsely high and completely unreliable.

The "common solutions" of recalibrating instruments or changing columns fail because they don't address this fundamental point of failure. You are trying to fix a problem in the control room when the leak is happening back at the source.

From Problem to Precision: Engineering the Right Solution

To permanently solve these issues, you don’t need to work harder at troubleshooting. You need a better gatekeeper. You need a septum that is purpose-built based on a deep understanding of these failure modes.

This is precisely where precision engineering makes a difference. An effective solution isn't just a piece of PTFE bonded to silicone; it's a component designed from the ground up to guarantee chemical purity and mechanical reliability. KINTEK’s PTFE/silicone septas are not just products; they are the embodiment of this solution-first mindset.

- To eliminate chemical contamination: Our components are made with exceptionally high-purity PTFE. This ensures that the only thing your instrument sees is your sample, providing a true and accurate baseline free of leachable impurities.

- To prevent mechanical failure: We utilize optimized silicone formulations and precision manufacturing processes that drastically reduce the risk of coring and fragmentation. Our septas are designed for clean puncturing and reliable resealing, protecting both your sample's integrity and your instrument's health, even across thousands of injections in a high-throughput workflow.

Choosing the right septum isn't a matter of luck; it's a matter of selecting a component engineered to prevent the root cause of your problems.

Beyond Troubleshooting: What Unwavering Data Integrity Unlocks

When you can finally trust your data, a fundamental shift happens in the lab. The focus moves away from reactive problem-solving and towards proactive discovery.

With a reliable seal, you can confidently run long, automated sequences overnight and on weekends, dramatically increasing your lab's throughput. You can perform stability studies on volatile compounds without fear of evaporation skewing your results. Your team can stop wasting time and resources chasing ghosts and instead invest that energy into developing new methods, accelerating product development, and making critical decisions with confidence. This isn't just about getting cleaner data; it's about unlocking your lab's full potential for innovation and efficiency.

The solution to your most persistent analytical challenges might be smaller than you think. Let our team of specialists help you move beyond troubleshooting and into a new era of confidence and productivity. We can help you select or custom-fabricate the precise component that solves your core problem, turning a point of failure into a source of strength. To discuss your unique project and ensure your results are always true, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions