It’s a scenario every analytical chemist knows and dreads. You’ve meticulously prepared your samples, programmed a long overnight sequence for your GC or LC, and you return the next morning expecting clean, actionable data. Instead, you find a mess: phantom peaks appearing out of nowhere, a baseline that drifts inexplicably, or analyte concentrations that are simply not reproducible. A full day's work—or more—is down the drain, and you have no idea why.

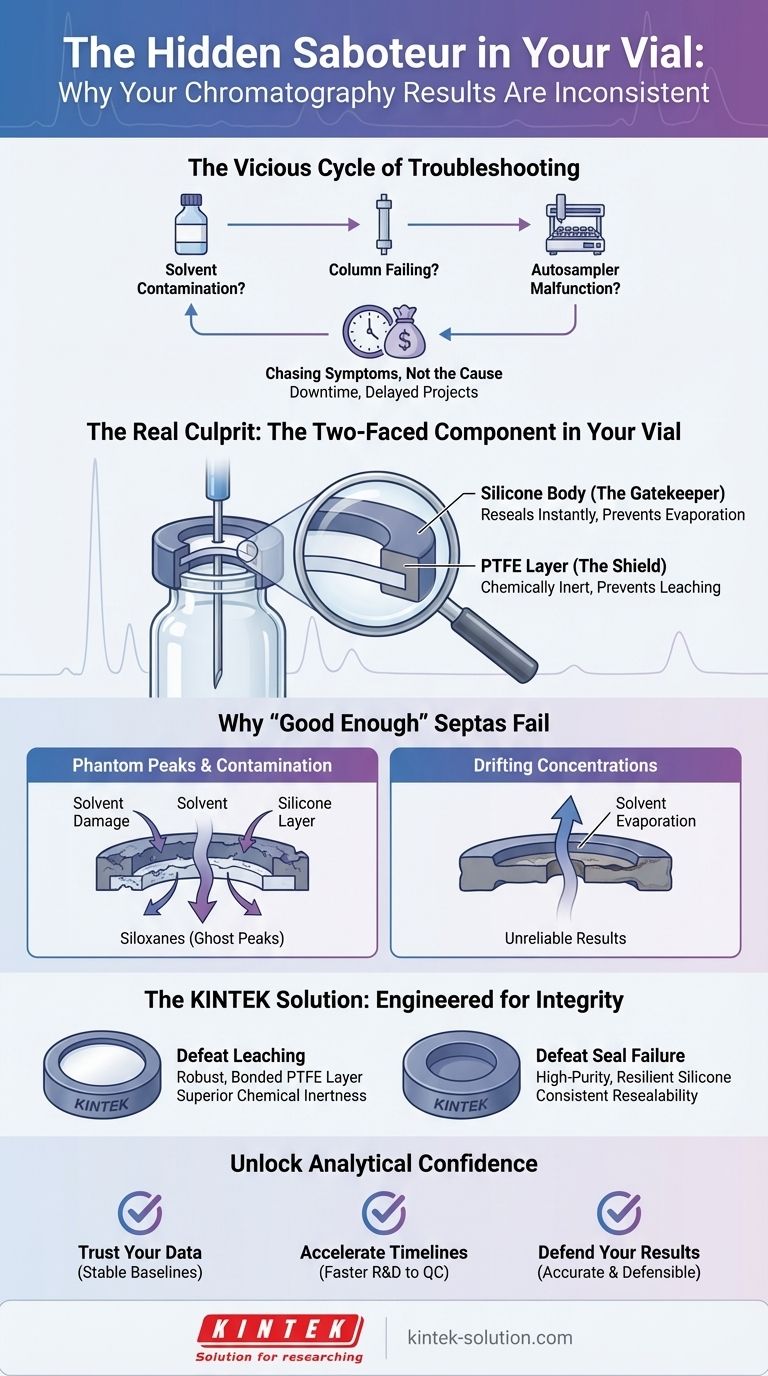

The Vicious Cycle of Troubleshooting: Chasing Symptoms, Not the Cause

When faced with this data integrity crisis, the typical response is a costly and time-consuming witch hunt. You start with the usual suspects:

- Is the solvent contaminated? You open a fresh, expensive bottle of high-purity solvent and re-run the samples. The problem persists.

- Is the column failing? You spend hours flushing the system, or worse, you install a brand-new, thousand-dollar column. Still no improvement.

- Is the autosampler malfunctioning? You start to question your multi-thousand-dollar instrument and schedule a service call, leading to days of downtime.

Each step burns through valuable time, resources, and budget. Project timelines get pushed back. In a pharmaceutical QC lab, it can even lead to delayed batch releases and difficult questions from management. Some labs, in an effort to cut costs, even reuse septas, unknowingly inviting this very problem and making the source of the error almost impossible to trace.

You’re stuck in a frustrating loop, treating symptoms without ever diagnosing the disease. The truth is, the culprit is often not a complex system failure, but one of the smallest, most overlooked components in your entire workflow.

The Real Culprit: The Two-Faced Component in Your Vial

The problem, in many cases, lies with the humble PTFE/silicone septum sealing your sample vial. It seems simple, but its performance is based on a delicate partnership between two materials with very different jobs. When this partnership fails, your analysis fails with it.

The Teflon Shield and The Silicone Gatekeeper

Think of your septum as a high-tech security door.

-

The PTFE Layer (The Shield): This ultra-thin layer faces your sample. PTFE is one of the most chemically inert materials known to science. Its job is to act as an impenetrable shield, preventing any reaction between your sample and the septum itself. It ensures nothing leaches out of the septum into your sample.

-

The Silicone Body (The Gatekeeper): This is the thick, elastic part of the septum. Its job is to form a perfect, gas-tight seal and, crucially, to reseal itself instantly after the autosampler needle withdraws. This prevents your sample's solvent from evaporating and stops air from getting in.

Why "Good Enough" Septas Inevitably Fail

The "common solutions" from the previous section fail because they ignore this fundamental mechanism. Your inconsistent results are often direct consequences of a septum failing at one of its two jobs:

- Phantom Peaks & Contamination: This happens when the PTFE shield is of poor quality, poorly laminated, or damaged. Aggressive solvents can then interact directly with the underlying silicone, causing it to swell and leach siloxanes and other impurities into your sample. These show up as the "ghost peaks" that ruin your chromatogram.

- Drifting Concentrations: This is a failure of the silicone gatekeeper. If the silicone is low-grade or has been punctured too many times, it loses its ability to reseal perfectly. Even a microscopic gap allows volatile solvent to evaporate, steadily increasing your analyte's concentration over a long run and making your results completely unreliable.

You aren't going crazy; your equipment isn't broken. You are simply the victim of a tiny component that failed to do its job.

From Understanding the Problem to Engineering the Solution

To truly guarantee data integrity, you don’t just need a septum; you need a septum that is engineered from the ground up with a deep understanding of these failure modes. It requires a flawless PTFE shield and a perfectly resilient silicone body.

This is the core principle behind KINTEK's precision-manufactured components. We don’t just sell septas; we engineer solutions to the problems that plague analytical labs. Our PTFE/silicone septas are not an afterthought—they are designed specifically to eliminate the root causes of analytical failure.

- To defeat chemical leaching: Our septas feature a robust, flawlessly bonded PTFE layer. We ensure superior lamination so that even when exposed to aggressive solvents used in pharmaceutical analysis, the shield remains intact. This provides the true chemical inertness your sensitive analyses demand, ensuring your sample's purity is never compromised.

- To defeat seal failure and evaporation: We use high-purity, high-performance silicone manufactured to precise tolerances. This guarantees an excellent, consistent seal and superior resealability, maintaining sample concentration and integrity from the first injection to the last, even during long, heated analytical runs.

Our septas are not a commodity; they are the embodiment of a solution, born from a deep understanding of the problem.

Beyond Troubleshooting: Unlocking a New Level of Analytical Confidence

When you eliminate the septum as a source of random error, the impact is transformative. The hours and days spent chasing phantom problems can be reinvested into what truly matters: your science.

Imagine a workflow where you can:

- Trust Your Data, Unconditionally: Run long, complex sequences overnight with the confidence that your baseline will be stable and your results reproducible in the morning.

- Accelerate Project Timelines: Move faster from R&D to QC to market by eliminating costly re-runs and troubleshooting-related delays.

- Push the Boundaries of Your Research: Confidently use a wider range of aggressive solvents for novel analyses, knowing your sample integrity is protected.

- Defend Your Results: Whether for an internal audit or a regulatory submission, you have rock-solid data that is accurate and defensible.

This isn't just about fixing a technical glitch; it's about elevating the reliability and potential of your entire laboratory.

Your analytical challenges are unique, and a one-size-fits-all component is rarely the right answer. Instead of letting a tiny, overlooked part dictate your success, it's time to choose a partner who understands the science behind the seal. Let's move the conversation from troubleshooting components to achieving your project goals. Contact Our Experts to discuss how precision-engineered PTFE components can bring a new level of confidence and consistency to your work.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives