The Point of Failure

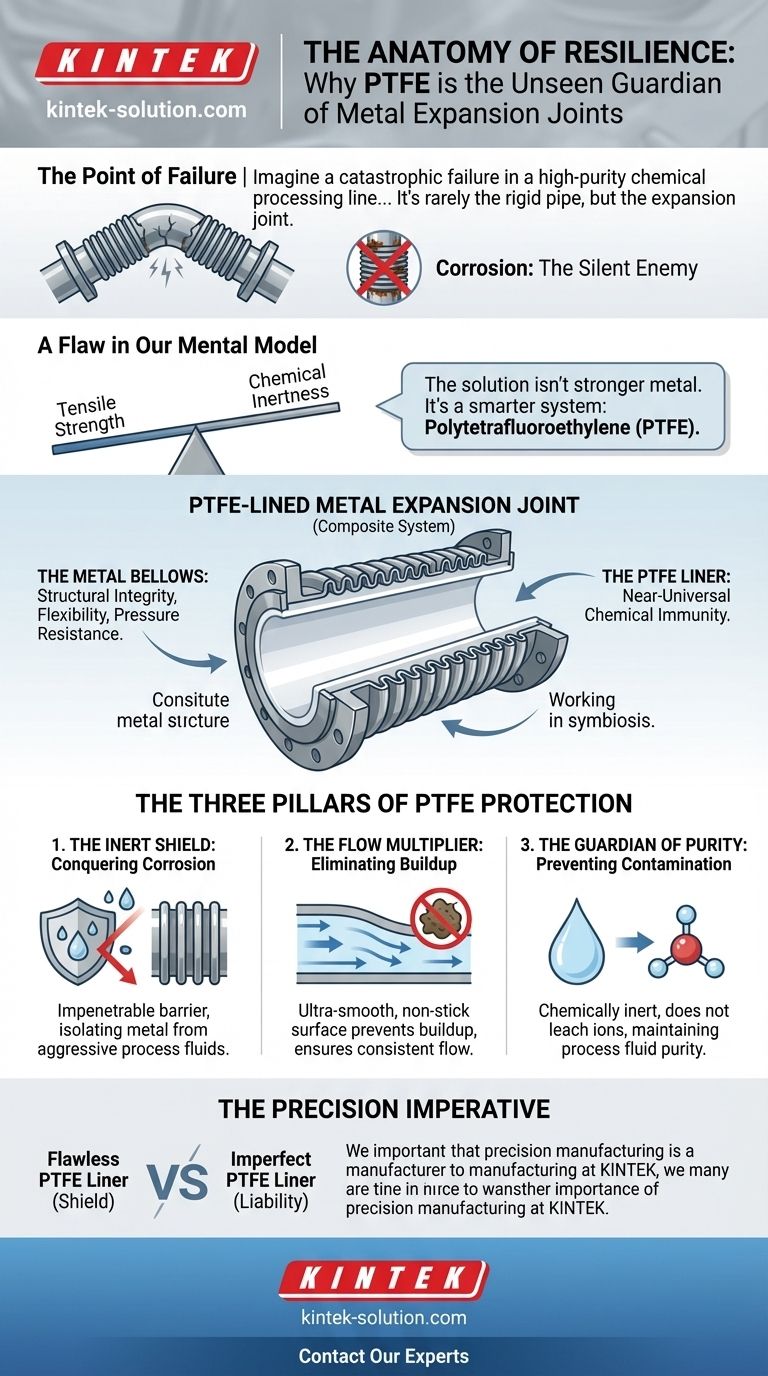

Imagine a catastrophic failure in a high-purity chemical processing line. It’s rarely the straight, rigid pipe that gives way. The failure almost always occurs at the point of greatest stress and movement: the expansion joint.

Engineers select robust metal expansion joints for their impressive mechanical strength. They are designed to withstand immense pressure, absorb vibration, and compensate for thermal expansion. We trust the steel. Yet, systems fail.

The root cause is often not a mechanical miscalculation but a chemical one. We focus so intently on pressure ratings and flexibility that we can overlook the slow, silent enemy: corrosion. A minuscule, persistent chemical attack on the metal bellows is all it takes to compromise the entire system.

A Flaw in Our Mental Model

This reveals a common cognitive bias in system design. We tend to prioritize visible, measurable strengths (like tensile strength) over invisible, preventative ones (like chemical inertness). The metal bellows are the muscle, but they have an Achilles' heel.

The solution isn't a stronger metal. It's a smarter system. It requires a shift in thinking—from designing for strength alone to designing for resilience. This is where a simple polymer, Polytetrafluoroethylene (PTFE), changes the entire equation.

A PTFE-lined metal expansion joint is not merely a metal joint with a coating. It is a composite system, a perfect marriage of two materials where each compensates for the other's weakness.

- The Metal Bellows: Provide the structural integrity, flexibility, and pressure resistance.

- The PTFE Liner: Provides near-universal chemical immunity.

This symbiotic design creates a component far more durable than the sum of its parts.

The Three Pillars of PTFE Protection

The PTFE liner's contribution isn't passive; it actively protects and enhances the system in three distinct ways.

1. The Inert Shield: Conquering Corrosion

The primary function of the PTFE liner is to serve as an impenetrable barrier. It becomes the primary wetted surface, completely isolating the structural metal from acids, caustics, and other aggressive process fluids. This single function transforms the expansion joint from a vulnerable component into a fortress, crucial in industries from semiconductor manufacturing to wastewater treatment.

2. The Flow Multiplier: Eliminating Buildup

PTFE is famous for its extremely low coefficient of friction. This creates an ultra-smooth, non-stick surface that prevents viscous fluids, sludge, or particulates from building up. This property is not just about convenience; it ensures consistent flow, reduces pressure drops, and simplifies system cleaning—an essential feature for hygienic applications in the pharmaceutical or food and beverage industries.

3. The Guardian of Purity: Preventing Contamination

In high-purity applications, the process fluid must remain pristine. Because PTFE is chemically inert, it does not leach ions or shed impurities into the media. A PTFE liner ensures that the product being transported—be it ultrapure water for semiconductor fabrication or a sensitive medical compound—remains uncontaminated by the system itself.

The Precision Imperative

However, this elegant solution is only as strong as its weakest link. The integrity of the composite system depends entirely on the perfection of the PTFE liner.

A liner with inconsistent wall thickness, pinholes, or surface imperfections is not a shield; it's a liability. It creates a false sense of security while allowing corrosive media to reach the metal bellows, accelerating failure precisely where you believe you are protected.

This is why the manufacturing process is paramount. Sourcing a liner isn't about acquiring a piece of plastic; it's about investing in a precision-engineered component. At KINTEK, we specialize in the custom fabrication of high-purity PTFE components. Our focus on precision production, from prototype to high-volume orders, ensures that every liner we deliver provides the flawless, uniform barrier required to guarantee the resilience of your entire system.

| Key Benefit | Role of the PTFE Liner |

|---|---|

| Corrosion Resistance | Acts as the primary barrier, shielding metal bellows from aggressive chemicals. |

| Non-Stick Surface | Prevents buildup of viscous fluids or particulates, ensuring smooth flow. |

| System Purity | Maintains media integrity by preventing contamination from metallic ions. |

| Temperature Range | Withstands wide temperature fluctuations, enhancing joint reliability. |

The Human Element: Execution is Everything

Even with the best components, success hinges on human discipline.

- Installation: Proper pipe alignment is non-negotiable. Misalignment creates unnatural stress on the liner, leading to folds or cracks that become failure points.

- Inspection: Regular visual checks for discoloration, wear, or damage are a critical part of any preventative maintenance protocol. The liner is your first line of defense; treat it as such.

Ultimately, choosing a PTFE-lined expansion joint is a strategic decision to build a more robust, reliable, and safer system. It’s an acknowledgment that true strength lies not just in resisting force, but in neutralizing threats before they can cause harm.

To ensure your critical systems are built on a foundation of chemical and mechanical resilience, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work