It’s a moment every design engineer dreads. The prototype, so flawless on the CAD screen, fails in the real world. Your new PTFE-lined catheter, designed for exceptional performance, suddenly kinks while navigating a simple test fixture. The flow is blocked. The test is a failure. Weeks of work and expensive materials are wasted, and you’re back at the drawing board with a frustrating question: what went wrong?

If this scenario feels uncomfortably familiar, you're not alone. This isn't just a catheter problem; it's a challenge that plagues engineers across semiconductor, industrial, and laboratory applications. A chemical processing hose collapses under vacuum. A high-purity fluid line is too rigid to install in a complex machine. The symptoms vary, but the cycle of failure is often the same.

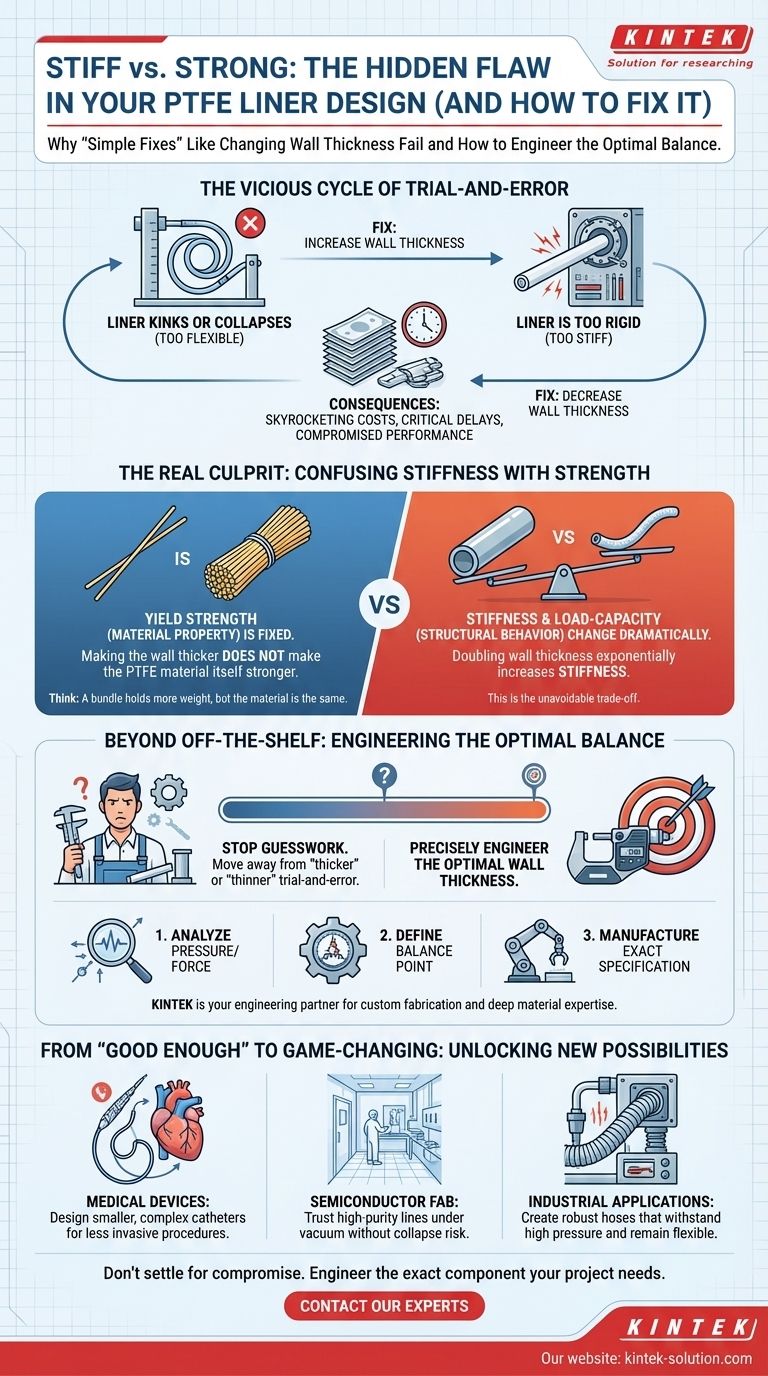

The Vicious Cycle of Trial-and-Error

When a PTFE liner fails, the instinct is to apply a simple, direct fix.

- Did it kink or collapse? "Simple," we think. "Let's increase the wall thickness to make it stronger."

- Was it too rigid to install or operate? "Easy fix. We'll just make the wall thinner for more flexibility."

You order a new prototype. It arrives. And all too often, you’ve just traded one problem for another. The new, thicker liner doesn't kink, but it's now so stiff it puts stress on mating components or makes the final device unusable. The new, thinner liner is wonderfully flexible, but it collapses the moment it’s put under negative pressure.

This cycle of trial, error, and costly re-prototyping isn't just a technical headache. It has serious business consequences:

- Skyrocketing Development Costs: Each failed prototype adds to material, tooling, and labor expenses.

- Critical Project Delays: What should have been a straightforward design phase becomes a months-long struggle, pushing back launch dates.

- Compromised Product Performance: You're forced to settle for a "good enough" design that doesn't quite meet performance targets, putting you at a disadvantage.

The reason these simple fixes fail is that they are based on a fundamental misunderstanding of how PTFE actually works.

The Real Culprit: Confusing Stiffness with Strength

The core of the problem lies in a common mix-up between a part’s structural behavior and its material properties.

Your PTFE Material Isn't Getting "Stronger"

Let's be clear: Yield strength is an intrinsic property of the PTFE material itself. It’s a fixed value, measured in PSI or MPa, that defines the maximum stress the material can take before it deforms permanently. Making a liner wall thicker or thinner does not change the yield strength of the PTFE.

Think of it like a single strand of uncooked spaghetti. It has a certain strength. If you grab a bundle of 20 strands, the bundle can hold much more weight before it breaks. You haven't made the spaghetti material itself stronger; you've just used more of it, increasing its overall load-bearing capacity.

This is exactly what happens when you thicken a PTFE wall. You increase the part's ability to withstand a total force (its load-bearing capacity), but you haven't made the material itself any stronger.

The Unavoidable Trade-Off: Stiffness vs. Flexibility

What does change, directly and unavoidably, is stiffness. Stiffness is the resistance to bending. When you double the wall thickness, you don't just double the stiffness—you increase it dramatically.

This is why your "simple fixes" backfire.

- When you thickened the wall to stop it from kinking, you weren't really making it "stronger." You were making it stiffer.

- When you thinned the wall to make it more flexible, you were accepting a lower load-bearing capacity.

The solution, therefore, isn't about finding a "stronger material." It's about precisely engineering the one variable that truly matters: the structural balance between integrity and flexibility for your specific application.

Beyond Off-the-Shelf: Engineering the Optimal Balance

To break free from the cycle of trial-and-error, you need to stop thinking in terms of "thicker" or "thinner." You need to start thinking in terms of the optimal wall thickness, engineered to the exact decimal point that delivers the performance you need without compromise.

This requires a tool capable of hitting that perfect target. The solution isn't just a part; it's a process rooted in deep material expertise and manufacturing precision. To solve this root problem, you need a partner who can:

- Analyze the specific forces at play in your application—pressure, vacuum, bend radius, and assembly stress.

- Define the precise point of balance where the liner has just enough rigidity to resist collapse, but remains flexible enough for its function.

- Manufacture a component to that exact specification, consistently and reliably.

This is precisely why we built KINTEK. We are not just a PTFE component supplier; we are engineering partners. Our foundation in precision production and custom fabrication is built on a deep understanding of this exact challenge. We leverage our expertise to move beyond generic, off-the-shelf sizes and help you engineer the component that is perfectly optimized for your application—from a single prototype to high-volume production. Our process is designed to deliver a part that isn't a compromise, but a solution.

From 'Good Enough' to Game-Changing: What Optimized PTFE Unlocks

When you stop fighting with your components and engineer them correctly from the start, you don't just solve a nagging problem. You unlock entirely new possibilities.

- Medical device engineers can now design smaller, more intricate catheters that can navigate complex vasculatures, enabling less invasive procedures.

- Semiconductor fab managers can trust their high-purity fluid and gas lines to perform flawlessly under vacuum without risk of collapse, boosting process reliability and yield.

- Industrial designers can create robust chemical hoses that withstand high pressures while remaining flexible enough for easy installation and maintenance in tight spaces.

Ultimately, mastering this trade-off is about more than just one liner. It's about accelerating your innovation, de-risking your product development, and building a final product that outperforms the competition because every single component is optimized to do its job perfectly.

Your project deserves more than a "good enough" solution born from frustrating compromises. It's time to engineer the exact component you need. Let's talk about the specific pressures, constraints, and goals of your project, and build a truly optimized solution together. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems