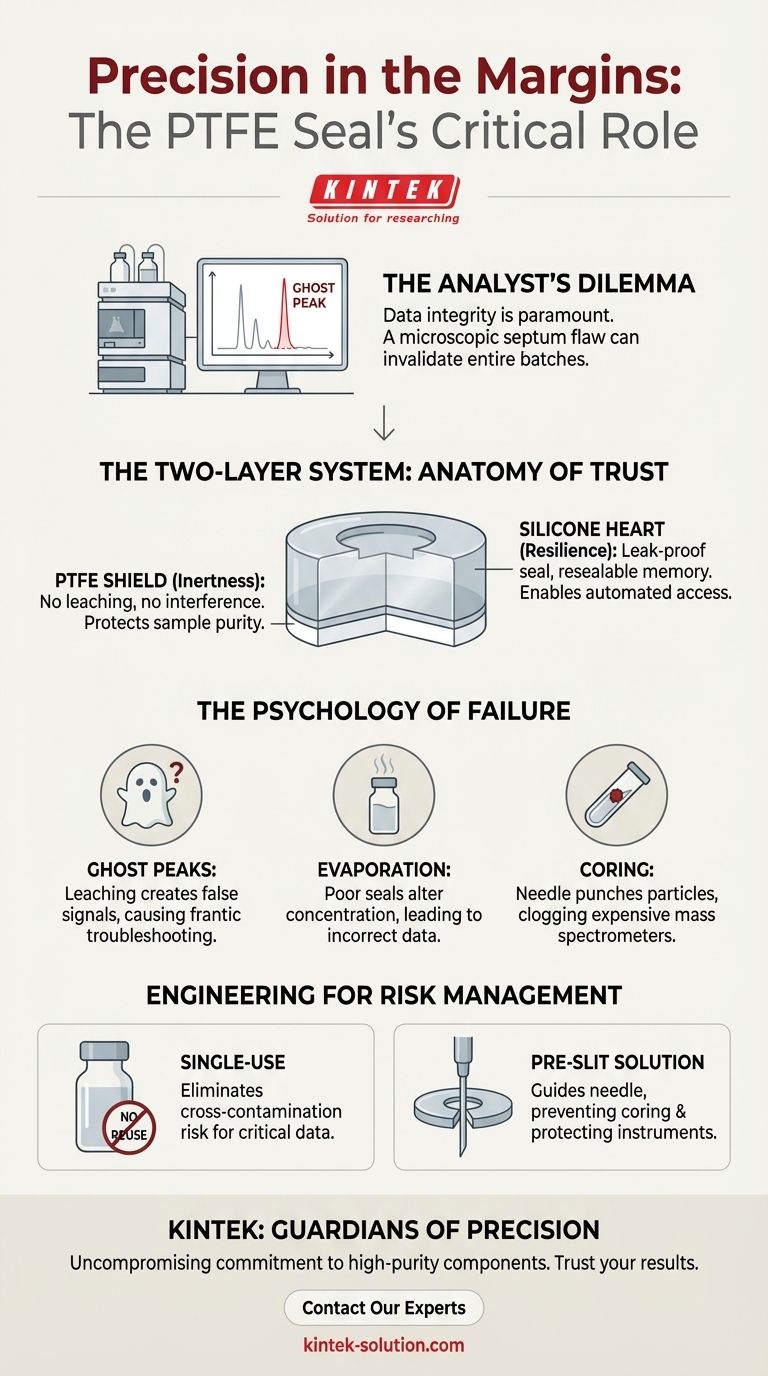

The Analyst's Dilemma

In pharmaceutical science, fortunes are built on data. An analyst running a High-Performance Liquid Chromatography (HPLC) analysis isn't just mixing chemicals; they are verifying the purity of a compound that could become a life-saving drug.

The pressure is immense. A single, unidentified peak on a chromatogram can invalidate an entire batch, trigger a costly investigation, and delay a critical timeline.

The source of such an error is often assumed to be a major failure in process or chemistry. But frequently, the culprit is microscopic. It’s a flaw in something no bigger than a fingernail: the vial septum.

The Anatomy of Trust: A Two-Layer System

A PTFE silicone septum is not a simple plug. It's an elegant piece of engineering designed to resolve a fundamental conflict: the need to keep a container hermetically sealed while also allowing repeated, clean access.

Its design is a partnership between two materials, each with a distinct and vital role.

The PTFE Shield: A Vow of Silence

The inner layer, facing the precious sample, is a micro-thin sheet of Polytetrafluoroethylene (PTFE). Its defining characteristic is its profound chemical inertness.

PTFE makes a simple promise to the sample: "I will not interfere." It doesn't leach impurities, react with aggressive solvents, or alter the sample's delicate chemical balance in any way. This inertness is the foundation of data integrity. Without it, you are not analyzing your sample; you are analyzing your sample plus contamination from its container.

The Silicone Heart: Resilience and Recovery

Bonded to the PTFE is a thicker, softer layer of high-purity silicone. This is the muscle. Its elasticity creates a firm, leak-proof seal against the vial's rim, protecting the contents from atmospheric contamination and evaporation.

More importantly, it has a memory. When a syringe needle pierces it, the silicone yields. When the needle is withdrawn, it recovers, resealing the puncture path. This remarkable resealability is what enables automated, high-throughput analysis and preserves the sample for confirmatory testing.

The Psychology of a Failed Analysis

A compromised septum doesn't just create bad data; it creates chaos. It introduces doubt, the most corrosive element in any scientific process.

- The Ghost in the Machine: When a non-PTFE seal leaches impurities, it can create "ghost peaks" in the analysis. This sends the team on a frantic hunt for a phantom contaminant, wasting hours or days troubleshooting equipment and re-validating methods.

- The Quiet Lie of Evaporation: A poor seal allows volatile solvents to evaporate, slowly but surely increasing the concentration of the active ingredient. The resulting data appears valid but is fundamentally wrong—a quiet lie that could lead to incorrect dosage calculations or a rejected regulatory submission.

- The Catastrophic "Coring" Event: "Coring" happens when a needle punches a tiny disc from the septum into the vial. This small particle can clog the delicate tubing of a multi-million dollar mass spectrometer, causing instrument downtime and expensive repairs.

Engineering for Unseen Risks

These failures are why selecting the right septum isn't a trivial choice about lab consumables. It's a strategic decision about risk management.

The Myth of Reusability

In a regulated environment, the idea of reusing a septum is a dangerous illusion. The minuscule cost saving is dwarfed by the unacceptable risk of cross-contamination. For any analysis that matters—from quality control to clinical trial data—septa must be single-use. The integrity of the result is paramount.

The Pre-Slit Solution

To prevent the mechanical failure of coring, a simple but brilliant innovation was introduced: the pre-slit septum. A small cross or star-shaped slit guides the needle, parting the material instead of punching through it. This dramatically reduces the piercing force required and virtually eliminates the risk of coring, protecting both the sample and the analytical instrument.

| Consideration | Low-Risk Application (e.g., R&D) | High-Risk Application (e.g., FDA Submission) |

|---|---|---|

| Purity | High-purity materials are preferred. | Only the highest-purity, certified materials are acceptable. |

| Design | Standard septa may suffice. | Pre-slit septa are mandatory to prevent coring. |

| Usage | Reusability might be considered (with caution). | Strictly single-use to eliminate cross-contamination. |

Ultimately, the septum is more than a seal. It's a guardian. Its performance reflects a lab's commitment to a culture of precision—a mindset where every detail is recognized as critical.

This philosophy of uncompromising precision is essential for components used in the semiconductor, medical, and laboratory fields. It demands manufacturing partners who understand that the reliability of a final product often depends on the integrity of its smallest parts. At KINTEK, we build custom and standard high-purity PTFE components, from seals to labware, with this exact principle in mind. We provide the foundational reliability so you can trust your results.

When the stakes are this high, your data deserves a guardian you can depend on. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault