When handling corrosive, toxic, or ultra-pure media, valve failures aren't just operational hiccups—they're potential disasters. PTFE-lined butterfly valves merge advanced material science with precision engineering to create barriers against leaks, contamination, and system breakdowns. Here’s how they deliver reliability where it matters most.

Safety Engineering in PTFE-Lined Butterfly Valves

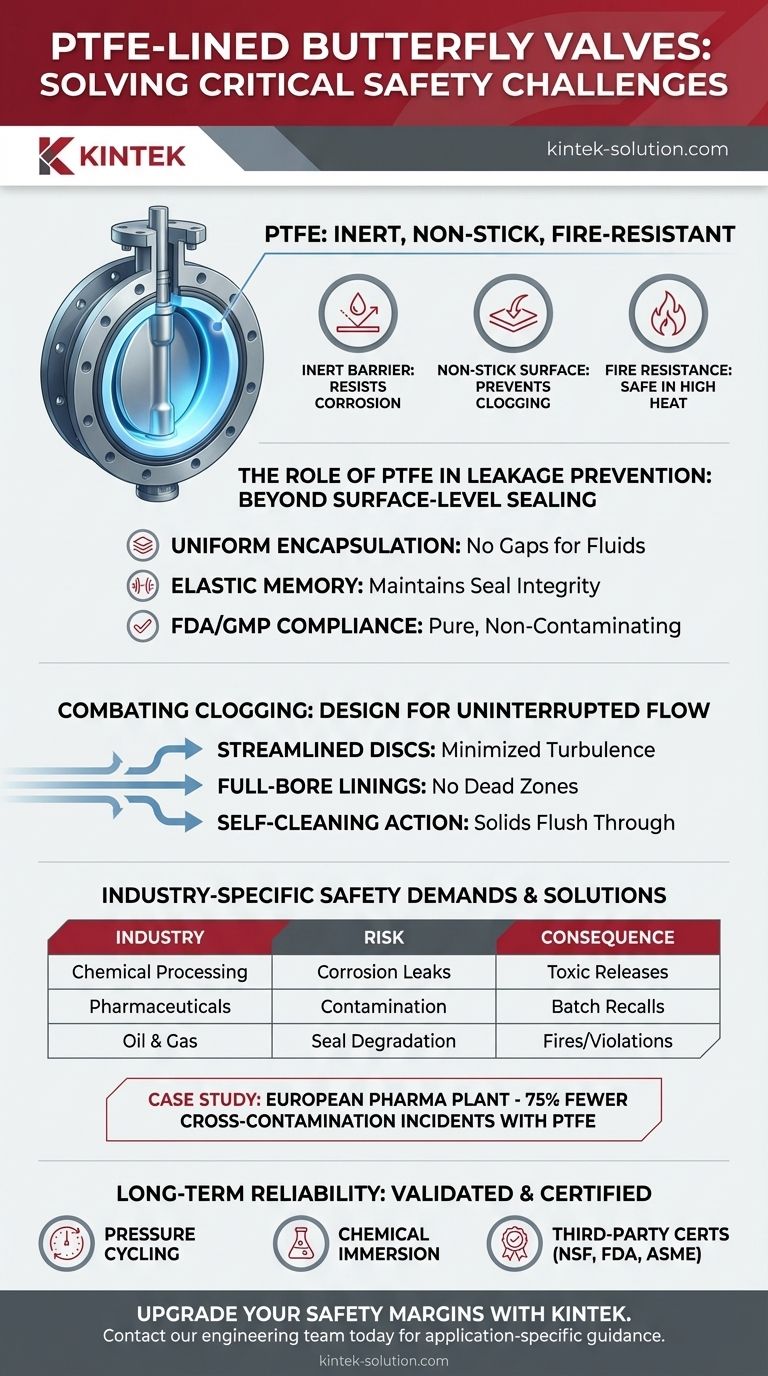

PTFE (polytetrafluoroethylene) transforms standard butterfly valves into safety-critical components. Unlike conventional designs, PTFE linings act as both a chemical shield and a fail-safe sealing layer. Research shows these valves reduce leakage incidents by over 90% in chemical processing plants compared to unlined alternatives.

Key Safety Mechanisms:

- Inert Barrier: PTFE's carbon-fluorine bonds resist virtually all acids, bases, and solvents, preventing corrosive attacks on metal valve bodies.

- Non-Stick Surface: The material’s low friction prevents clogging from viscous or particulate-laden fluids, common in wastewater and pharmaceutical applications.

- Fire Resistance: PTFE doesn’t ignite, a critical feature for oil/gas or high-temperature industrial settings.

For engineers, this means fewer emergency shutdowns and lower exposure risks for personnel.

The Role of PTFE in Leakage Prevention: Beyond Surface-Level Sealing

Leaks often start at microscopic gaps between valve components. PTFE linings address this through:

- Uniform Encapsulation: The lining molds seamlessly to the valve body, eliminating gaps where fluids could penetrate.

- Elastic Memory: Even under pressure fluctuations, PTFE maintains seal integrity without permanent deformation (unlike rubber or silicone).

- FDA/GMP Compliance: In food/pharma, PTFE’s purity prevents contamination—a non-negotiable for meeting regulatory audits.

Example: In semiconductor fabs, PTFE-lined valves prevent trace metal leaching into ultra-pure chemicals, safeguarding billion-dollar production batches.

Combating Clogging: Design Features That Ensure Uninterrupted Flow

Material buildup isn't just annoying—it's a safety hazard. PTFE’s non-stick properties combine with smart engineering to prevent flow disruptions:

- Streamlined Discs: Angled designs minimize turbulence where particles could accumulate.

- Full-Bore Linings: Smooth PTFE surfaces extend through pipe connections, eliminating dead zones.

- Self-Cleaning Action: The lining’s slickness encourages solids to flush through rather than adhere.

Industries like pulp/paper or mining rely on these features to avoid unplanned maintenance in abrasive slurry systems.

Industry-Specific Safety Demands: Where PTFE Valves Become Non-Negotiable

| Industry | Risk Mitigated by PTFE Valves | Failure Consequences |

|---|---|---|

| Chemical Processing | Corrosion-induced leaks | Toxic releases, equipment damage |

| Pharmaceuticals | Contamination from valve materials | Batch recalls, regulatory fines |

| Oil & Gas | Seal degradation under high heat/pressure | Fires, environmental violations |

Case Study: A European pharma plant replaced rubber-sealed valves with PTFE-lined units, cutting cross-contamination incidents by 75% in sterile API production.

Long-Term Reliability and Compliance: Certifications and Testing Protocols

PTFE valves aren't just durable—they're provably safe. Leading manufacturers validate performance through:

- Pressure Cycling Tests: Simulating decades of use to confirm seal longevity.

- Chemical Immersion Trials: Exposing linings to aggressive media for 10,000+ hours.

- Third-Party Certifications: NSF/ANSI, FDA 21 CFR, and ASME B16.34 compliance.

Pro Tip: When selecting valves, verify testing matches your actual operating conditions—especially for extreme pH or temperature swings.

Engineered Safety Starts With the Right Materials

PTFE-lined butterfly valves exemplify how material innovation meets real-world safety needs. Whether preventing leaks in a sulfuric acid line or ensuring vaccine purity, their reliability stems from PTFE’s unique chemistry and purpose-driven design.

Upgrade Your Safety Margins with KINTEK

For industries where failure isn't an option, KINTEK's PTFE components—from custom valve linings to semiconductor-grade labware—deliver precision-engineered solutions. Let’s collaborate to fortify your critical systems. Contact our engineering team today for application-specific guidance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work