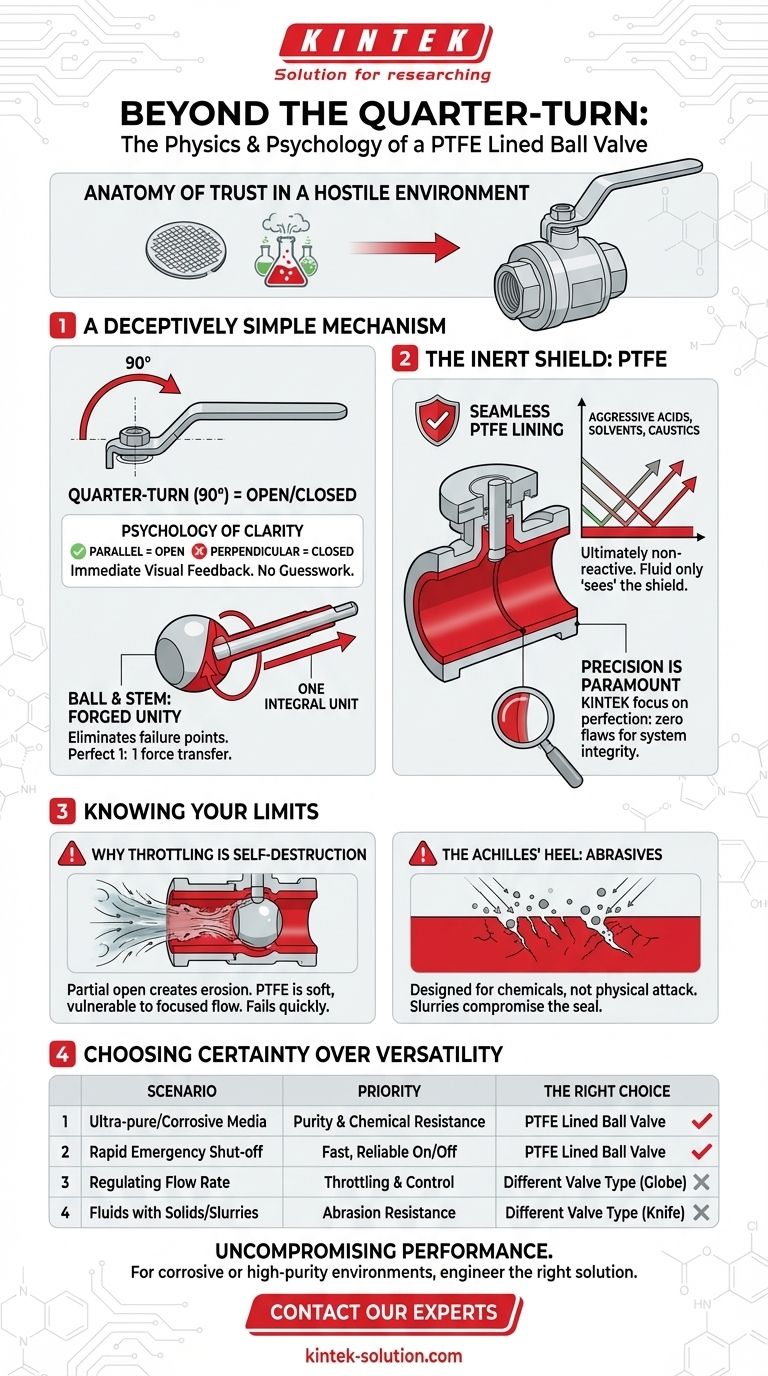

The Anatomy of Trust in a Hostile Environment

Imagine a semiconductor fabrication plant. Inside, billions of microscopic transistors are etched onto silicon wafers using brutally corrosive acids. A single drop of contamination, a single microscopic leak, can ruin millions of dollars in product.

Now, picture a chemical processing facility where volatile reagents are mixed under pressure. Here, a leak isn't just a financial loss; it's a catastrophic safety failure.

In these environments, you don't need components that are just "good enough." You need systems built on a foundation of absolute certainty. This is where we must appreciate the quiet genius of a component often overlooked: the PTFE lined ball valve. It is a masterclass in designing for trust where trust is the only thing that matters.

A Deceptively Simple Mechanism

At its heart, the valve is an exercise in elegant simplicity. A 90-degree turn of a handle—a quarter-turn—is all it takes to go from fully open to fully closed.

This isn't just about speed, though it is crucial for emergency shut-offs. It's about psychology. The handle's position provides immediate, unambiguous visual feedback. Parallel is open. Perpendicular is closed. There is no guesswork, no ambiguity, no "partially open" state to misinterpret. In a high-stakes system, clarity is safety.

The Ball and Stem: Forging an Unbreakable Will

The operator's intent is transferred to the flow-blocking ball via a stem. In superior designs, the ball and stem are forged as a single, integral unit.

Why does this small detail matter? Because it eliminates a potential point of failure. A two-piece design could twist, slip, or break under stress. An integral design ensures a perfect, 1:1 transfer of force. It forges an unbreakable link between human command and mechanical action. The valve does exactly what you tell it to, every single time.

The Inert Shield: Where Material Science Becomes a Promise

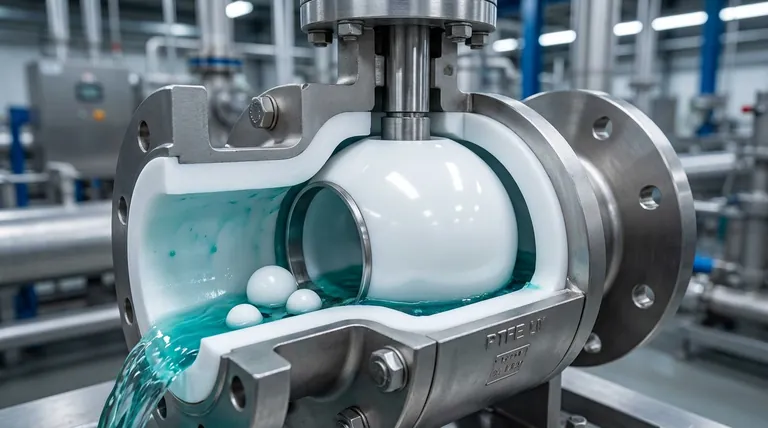

The true brilliance of this valve lies in its lining. The interior of the valve body, the entire surface of the ball—every part the fluid could possibly touch—is coated in a seamless layer of Polytetrafluoroethylene (PTFE).

PTFE is a marvel of material science. It is one of the most non-reactive substances known to man. It is the ultimate stoic, refusing to engage with the aggressive acids, solvents, and caustics that would destroy even specialized metal alloys. The fluid passing through the valve never "sees" the structural metal. It only ever sees the impassive PTFE shield.

This is where the precision of the lining becomes paramount. A microscopic flaw, an invisible pinhole, or an inconsistent thickness, and the entire system's integrity is compromised. This is why specialized manufacturers like KINTEK focus obsessively on the quality of PTFE components, from seals to custom liners. The promise of inertness is only as good as the perfection of its application.

The Wisdom of Knowing Your Limits

A great design understands not only what it is for, but also what it is not for. The PTFE lined ball valve is designed for one job: absolute, on/off isolation. Its limitations are a direct consequence of its specialized strengths.

Why Throttling Is an Act of Self-Destruction

It is tempting to use a ball valve to regulate or "throttle" flow by leaving it partially open. This is a critical mistake.

A partially open ball creates high-velocity, turbulent flow that acts like a sandblaster against the soft PTFE lining. The very properties that make PTFE chemically inert—its softness and lubricity—make it vulnerable to this kind of focused, physical erosion. The valve will quickly fail, leaking even when fully closed. It is a tool designed for two states: order (open) and security (closed). Introducing the chaos of throttling destroys it.

The Achilles' Heel: Abrasives

Similarly, the valve's PTFE shield is designed to repel chemical attacks, not physical ones. Slurries or fluids containing abrasive particles will scratch and gouge the soft lining, compromising the bubble-tight seal. It is a chemical shield, not a suit of armor.

Choosing Certainty Over Versatility

The decision to use a PTFE lined ball valve is a decision to prioritize safety and purity above all else. You choose it when the cost of a leak or contamination is unacceptably high.

| Scenario | Your Priority | The Right Choice |

|---|---|---|

| Handling ultra-pure or corrosive media | Purity & Chemical Resistance | PTFE Lined Ball Valve |

| Needing rapid emergency shut-off | Fast, Reliable On/Off Control | PTFE Lined Ball Valve |

| Regulating the flow rate of a fluid | Throttling & Control | A different valve type (e.g., Globe) |

| Moving fluids with solids/slurries | Abrasion Resistance | A different valve type (e.g., Knife) |

The integrity of these critical systems doesn't come from the valve body alone, but from the flawless PTFE components within. Ensuring that liner, that seal, is manufactured to perfection is the first and most important step toward building a truly robust process. If your application demands uncompromising performance in corrosive or high-purity environments, we can help you engineer the right solution. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The PTFE Paradox: Why Using Less of This 'Miracle' Material Unlocks More Performance

- The Weakest Link: How PTFE Bellows Engineer Resilience into Critical Systems

- When 'Tougher' Isn't Enough: The Hidden Reason Your Industrial Components Are Failing

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics