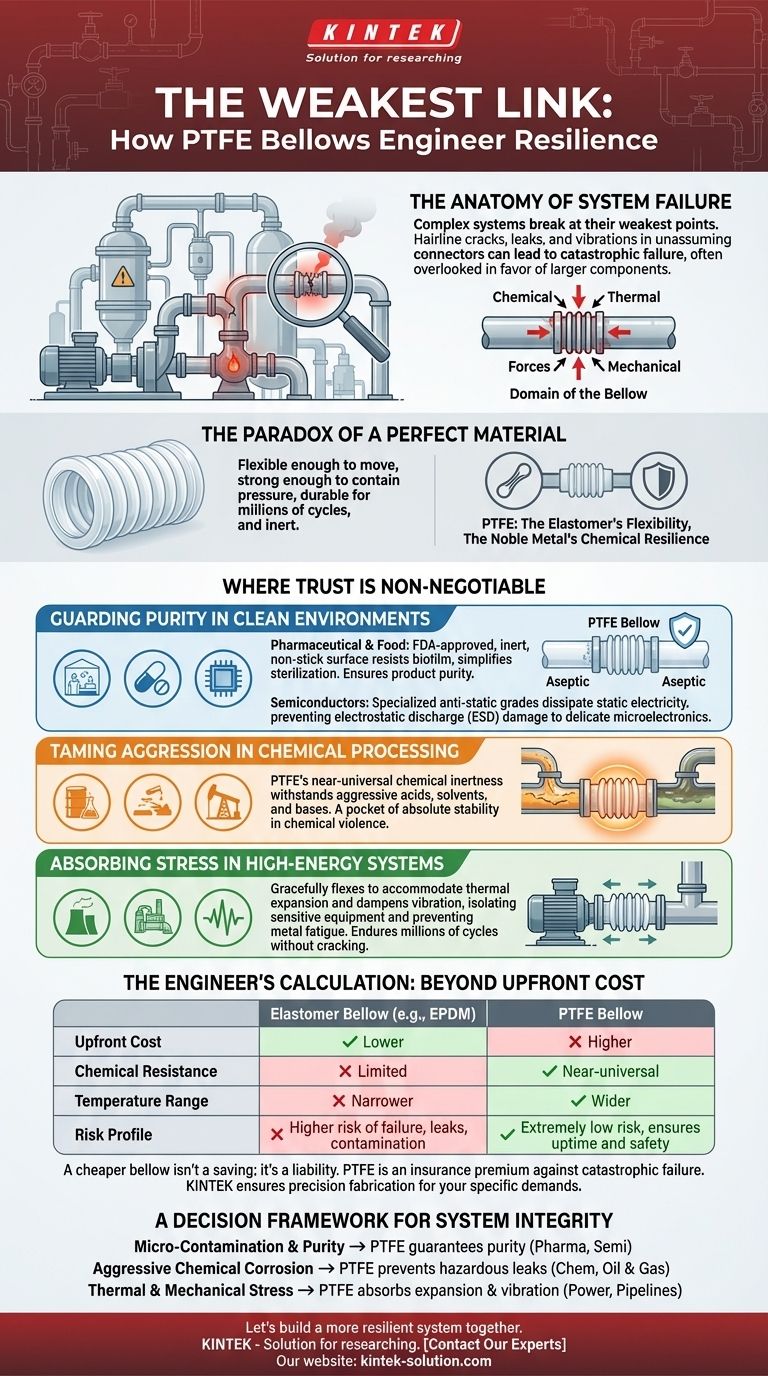

The Anatomy of System Failure

A complex system—be it a pharmaceutical production line, a chemical reactor, or a semiconductor fab—is an intricate chain of dependencies. We invest immense resources in the primary components: the pumps, the vessels, the monitoring equipment. Yet, catastrophic failures often originate not in these monoliths, but in the small, unassuming connections between them.

A hairline crack in a pipe joint. A microscopic leak from a valve seal. A vibration that propagates unabated until a critical weld fractures.

From a psychological standpoint, our attention is drawn to the biggest, most expensive parts of the system. We overlook the connectors, the joints, the flexible interfaces. Yet, this is precisely where the greatest stresses—chemical, thermal, and mechanical—are concentrated. This is the domain of the bellow, an engineered component designed to absorb the chaos that would otherwise break the system.

The Paradox of a Perfect Material

The choice of material for a bellow is a profound engineering decision. It must be flexible enough to move, yet strong enough to contain pressure. It must be durable enough to withstand millions of cycles, yet inert enough not to react with its environment.

This is where Polytetrafluoroethylene (PTFE) presents a unique paradox. It combines seemingly contradictory properties into a single, elegant solution. It offers the flexibility of an elastomer with the chemical resilience approaching that of a noble metal. This unique combination makes it the default choice for guarding the integrity of our most vulnerable systems.

Where Trust is Non-Negotiable

In certain environments, "good enough" is a recipe for disaster. The choice of a component is not just about performance, but about trust. Engineers choose PTFE bellows when the cost of failure—in financial, safety, or reputational terms—is simply too high.

Guarding Purity in Clean Environments

In pharmaceutical and semiconductor manufacturing, the enemy is contamination. A single foreign particle or a trace chemical leach can compromise a multi-million dollar batch of medicine or a wafer of microchips.

- Pharmaceutical & Food: PTFE is FDA-approved, fundamentally inert, and possesses a non-stick surface that resists biofilm buildup and simplifies sterilization. A PTFE bellow in an aseptic valve doesn't just connect two pipes; it creates an impenetrable, sterile barrier that ensures product purity.

- Semiconductors: Standard polymers can build up static electricity, and a sudden electrostatic discharge (ESD) can destroy delicate microelectronics. Specialized anti-static PTFE grades safely dissipate this charge, eliminating a silent but potent threat in the cleanroom.

Taming Aggression in Chemical Processing

Imagine a chemical plant: a labyrinth of pipes carrying fluids that can dissolve metal. Here, a bellow is the last line of defense. Its job is to accommodate movement and vibration while containing substances that are actively trying to destroy it.

PTFE's near-universal chemical inertness means it doesn't degrade when exposed to the most aggressive acids, solvents, and bases. A PTFE bellow isn't just a flexible connector; it's a pocket of absolute stability in an environment of chemical violence.

Absorbing Stress in High-Energy Systems

Thermal expansion is a relentless force. In power generation or petrochemical pipelines, temperature fluctuations cause rigid pipe systems to expand and contract, placing immense stress on welds and joints. Vibration from pumps and turbines adds another layer of destructive energy.

A PTFE bellow acts as an engineering shock absorber. It gracefully flexes to accommodate thermal expansion and dampens vibration, isolating sensitive equipment and preventing metal fatigue across the entire system. It endures these stresses for millions of cycles without cracking, extending the life of everything it's connected to.

The Engineer's Calculation: Beyond Upfront Cost

While PTFE is a premium material, seasoned engineers understand that its true value isn't measured by its initial price. The calculation is about total cost of ownership, which is fundamentally a risk assessment.

| Decision Factor | Elastomer Bellow (e.g., EPDM) | PTFE Bellow |

|---|---|---|

| Upfront Cost | Lower | Higher |

| Chemical Resistance | Limited to specific families | Near-universal |

| Temperature Range | Narrower | Wider |

| Risk Profile | Higher risk of premature failure, leaks, and contamination in aggressive environments. | Extremely low risk, ensuring system uptime and safety. |

| True Cost | The cost of the bellow + the potential cost of a failed batch, downtime, or a safety incident. | A predictable investment in long-term system reliability. |

A cheaper bellow isn't a saving; it's a liability. The higher investment in a PTFE component is an insurance premium against catastrophic failure.

This is where manufacturing expertise becomes critical. A superior material is only as effective as its fabrication. Turning raw PTFE into a precision bellow that meets exacting tolerances for a semiconductor or medical application requires specialized knowledge. At KINTEK, we work with engineers from prototype to high-volume production, ensuring that the design and execution of the component are perfectly matched to the system's demands.

A Decision Framework for System Integrity

Choosing the right bellow isn't about the component itself; it's about identifying the primary threat to your system's integrity.

| If Your Primary Threat Is... | Your Environment Is Likely... | Why a PTFE Bellow Is the Solution |

|---|---|---|

| Micro-Contamination & Purity | Pharmaceutical, Food & Beverage, Semiconductor | Its inert, non-stick surface guarantees purity. Anti-static grades prevent ESD. |

| Aggressive Chemical Corrosion | Chemical Processing, Oil & Gas | Its near-universal chemical resistance prevents degradation and hazardous leaks. |

| Thermal & Mechanical Stress | Power Generation, Industrial Pipelines | It absorbs expansion and vibration, preventing fatigue in surrounding equipment. |

When the integrity of your entire system rests on a single, flexible component, precision isn't just a goal; it's a prerequisite. At KINTEK, we specialize in manufacturing custom PTFE bellows, seals, and liners engineered for the world's most demanding applications.

Let's build a more resilient system together. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure