The Milliseconds That Matter

In baseball, victory and defeat are measured in fractions. A tenth of a second in a runner's sprint, a few millimeters in a bat's position, a single mile per hour on a fastball.

This obsession with marginal gains forces players and engineers to look beyond raw talent and into the laws of physics. They hunt for any variable that can be controlled, any inefficiency that can be eliminated. Most of these variables come down to one fundamental force: friction.

Friction is the enemy of speed and the author of wear. In a sport decided by explosive, repetitive motion, overcoming it is not just an advantage; it's the entire game.

The Quiet Work of Low Friction

This is where material science enters the conversation. Polytetrafluoroethylene (PTFE) possesses a molecular structure that gives it one of the lowest coefficients of friction of any solid material. It's exceptionally "slippery."

This property isn't about magic; it's about physics. Its non-reactive, stable molecular bonds create a surface that other materials glide over with minimal resistance. Applying this principle to equipment fundamentally changes the equation of performance and durability.

The Swing and the Drag

The most intuitive application is on a baseball bat. A PTFE coating reduces the friction between the bat and the air, however minutely. In a game of milliseconds, this reduction in aerodynamic drag can translate into a faster swing, which in turn creates a higher exit velocity.

But this surface-level solution highlights a deeper principle. While a coating provides a temporary benefit, the true potential of PTFE is unlocked when it becomes an integral, structural part of the machine itself.

Engineering Consistency: The Heart of the Machine

Consider the automated pitching machine—the unsung hero of batting practice. Its only job is to be predictable. A machine that throws inconsistently doesn't just waste time; it ingrains bad habits and erodes a batter's confidence.

The Problem of Mechanical Variance

The enemy of a pitching machine is variance. It stems from two sources: friction and wear. The wheels that grip and propel the ball are under constant stress. As they wear down, their surface changes. Friction becomes inconsistent. The grip falters.

A pitch that was supposed to be a 90 mph fastball down the middle becomes an 88 mph slider in the dirt. The trust between the player and the machine is broken.

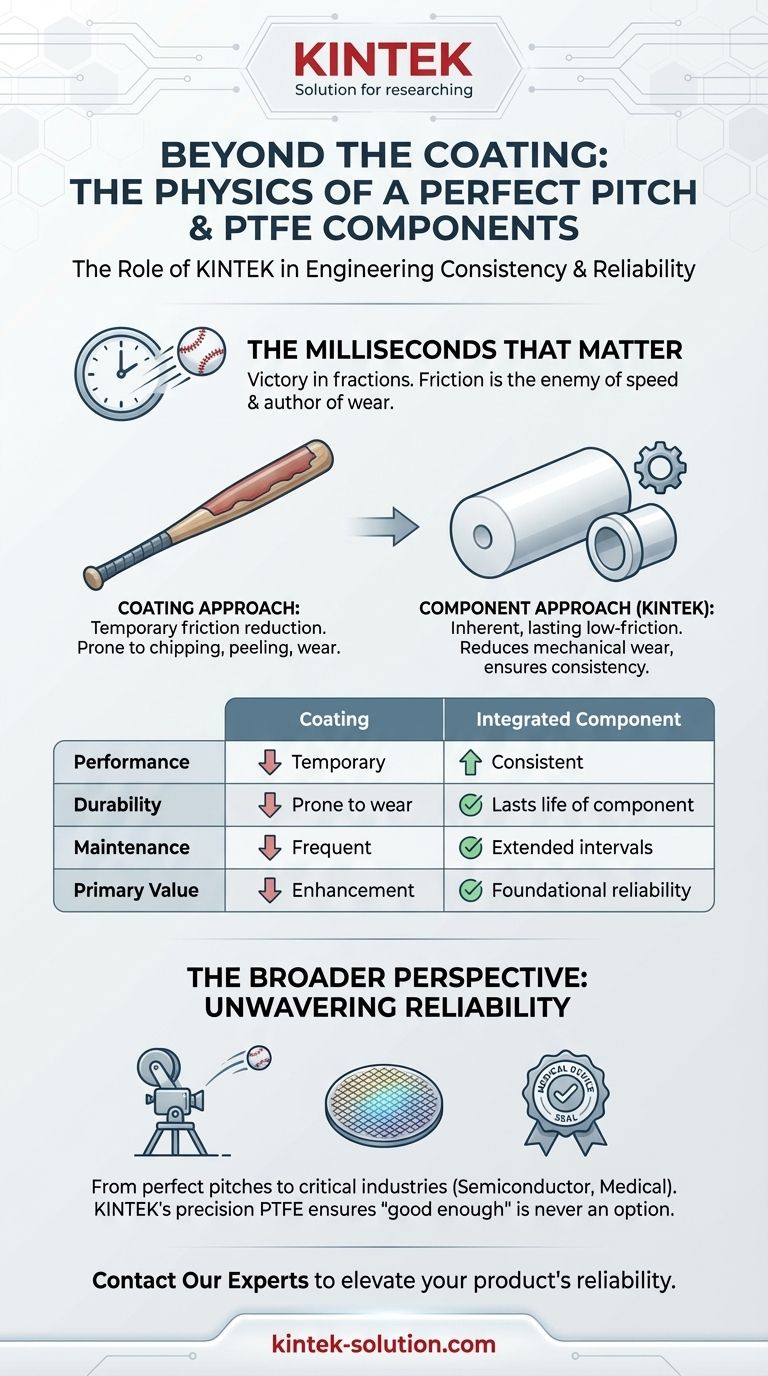

From Coating to Component: A More Robust Solution

While a PTFE coating on the launching wheels can help, it's a temporary fix on a high-wear surface. The coating can chip, peel, or wear away, reintroducing the very inconsistency it was meant to solve.

A more robust engineering solution is to build the machine with components made from solid PTFE or a filled PTFE composite. Instead of a coated wheel, imagine a precision-machined PTFE roller or a self-lubricating PTFE bushing for the motor's rotating assembly.

These are not just parts; they are systems designed for endurance.

- Solid PTFE rollers provide a consistently low-friction surface that doesn't degrade. The property is inherent to the material, not a thin layer on top.

- PTFE bushings and seals within the mechanics reduce wear on the motor and moving parts, ensuring the machine operates at its specified speed, day after day.

This is the difference between painting a surface and forging the engine block. One is an application; the other is a core design principle.

A Broader Perspective on Reliability

The need for unwavering reliability is not unique to baseball. The same principles that guarantee a perfect pitch are essential in far more critical environments.

In semiconductor manufacturing, a microscopic flake of a worn component can ruin millions of dollars in silicon wafers. In medical devices, a seal's failure can have life-or-death consequences.

Industries like these rely on KINTEK's precision-fabricated PTFE components because "good enough" is never an option. The material's purity, chemical inertness, and predictable performance under stress are non-negotiable. When a component is machined from a solid block of PTFE to exact tolerances, its performance isn't a feature—it's a guarantee.

This provides a valuable perspective. If the material science is trusted to perform in a sterile cleanroom or a life-saving device, its ability to elevate the reliability of a pitching machine is beyond question.

| Application Focus | Surface Coating Approach | Integrated Component Approach (KINTEK) |

|---|---|---|

| Performance | Provides temporary friction reduction. | Ensures consistent, predictable performance. |

| Durability | Prone to chipping, peeling, and wear. | Inherent properties last the life of the component. |

| Maintenance | May require frequent re-application. | Reduces mechanical wear and extends service intervals. |

| Primary Value | A performance enhancement. | A foundational element of reliability and longevity. |

True competitive advantage rarely comes from a simple, superficial fix. It is engineered from the inside out, built upon materials and components that you can trust to perform without fail. The goal isn't just a faster swing or a better pitch, but the confidence that comes from knowing your equipment will work exactly as designed, every single time.

To explore how precision-engineered PTFE components can bring a new level of reliability and performance to your products, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

Related Articles

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure